Exploring the Capabilities of a Laser Cutter CO2: A Comprehensive Guide

Laser technology has revolutionized various industries, offering precision, efficiency, and versatility that traditional methods often struggle to match. Among the many types of laser cutters available, the CO2 laser cutter stands out as a powerful tool for cutting and engraving metal and other materials. This article delves into the features, benefits, and applications of a laser cutter CO2, helping you understand why it has become an essential tool in modern manufacturing and craftsmanship.

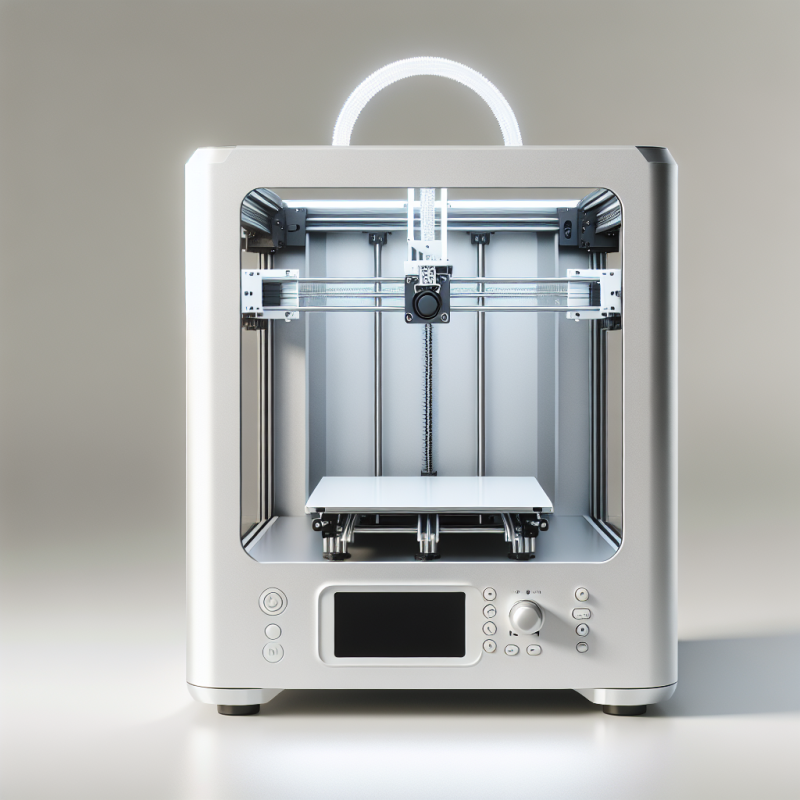

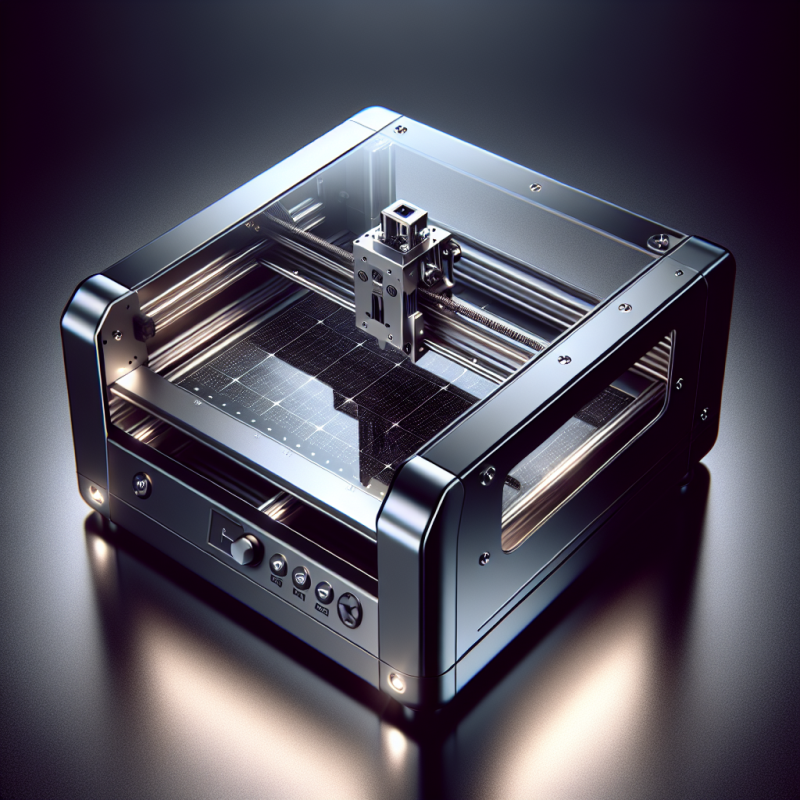

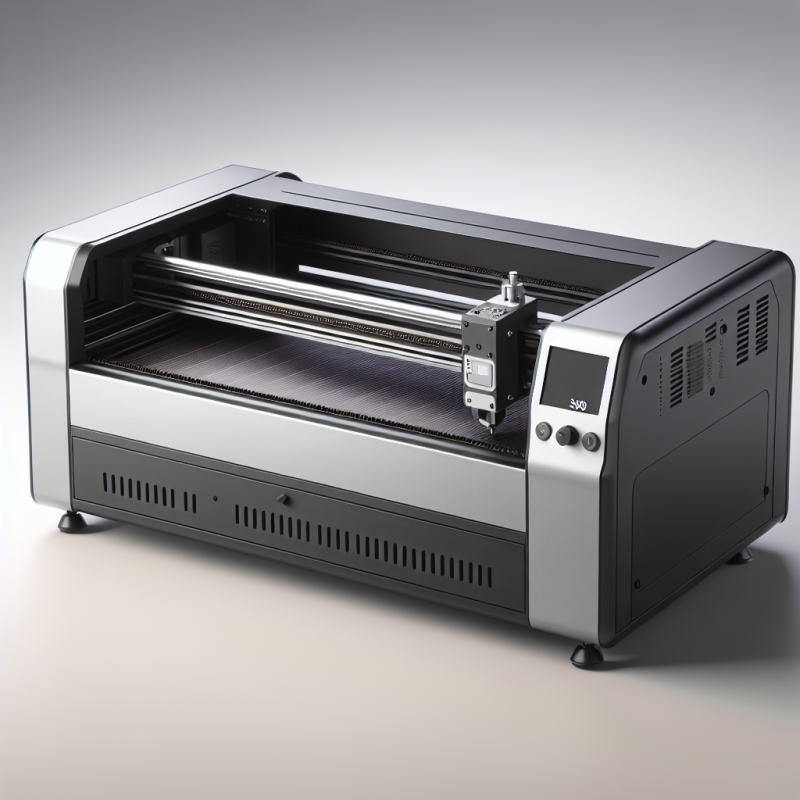

What Is a Laser Cutter CO2?

A laser cutter CO2 is a machine that uses a high-power laser to cut, engrave, or mark materials. Unlike traditional cutting methods, which rely on mechanical tools, the laser cutter CO2 delivers unparalleled precision and speed. The “CO2” in its name refers to the gas used within the laser tube, which generates the beam through electrical stimulation. This process creates a highly focused light source capable of melting, burning, or vaporizing materials with incredible accuracy.

The laser cutter CO2 is particularly popular for working with metal, as it can handle thick sheets and intricate designs without compromising quality. It is also widely used in industries such as signage production, jewelry making, and architectural detailing. If you’re considering investing in this technology, understanding its inner workings and benefits is essential.

How Does a Laser Cutter CO2 Work?

The operation of a laser cutter CO2 involves several key components:

- A CO2 laser tube filled with gas that generates the laser beam

- Mirrors or optical elements to focus and direct the beam

- A CNC (Computer Numerical Control) system for precise control

- An assist gas, such as oxygen or compressed air, to blow away molten material

When the laser is activated, it emits a high-energy beam that heats the material to its melting point. The assist gas then removes the molten material, creating a clean cut. This process is not only fast but also highly accurate, making it ideal for complex designs and tight tolerances.

Why Choose a Laser Cutter CO2?

There are several reasons why a laser cutter CO2 is a preferred choice over traditional cutting methods:

- Precision Cutting: The laser beam’s focus allows for intricate details and clean edges, even in thick materials.

- Speed: Compared to mechanical tools, the laser cutter CO2 can complete tasks much faster, reducing production time.

- Versatility: It can work with a wide range of materials, including metal, wood, plastic, and glass.

- Cost-Effective: Minimal material waste and reduced labor costs make it an economical choice for businesses.

If you’re working on custom projects or mass production, the laser cutter CO2 offers the flexibility to handle both with ease. Its ability to produce high-quality results consistently makes it a valuable asset in any workshop or manufacturing facility.

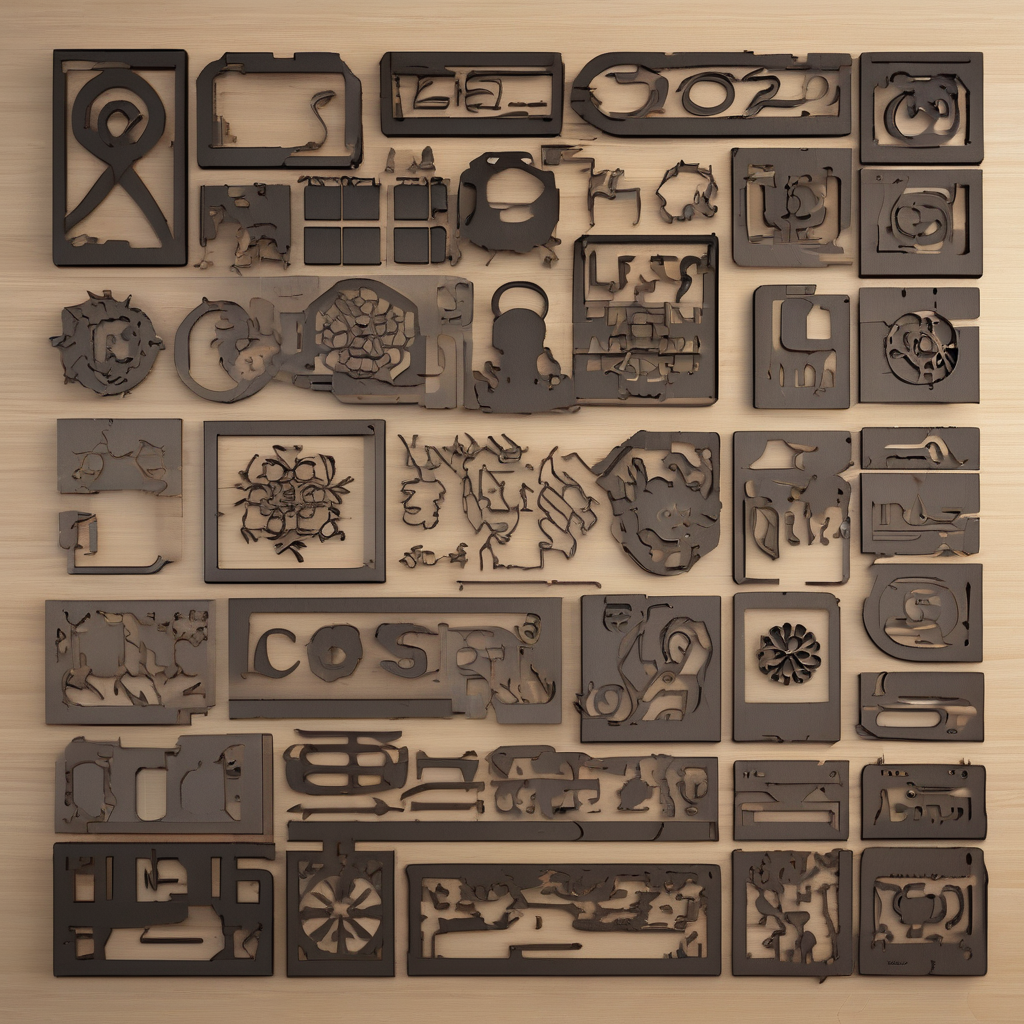

Applications of a Laser Cutter CO2

The versatility of a laser cutter CO2 means it can be applied to numerous industries and projects. Here are some common uses:

- Metal Engraving: Create detailed designs, logos, or text on metal surfaces with exceptional clarity.

- Cutting Thick Materials: Handle sheets of steel, aluminum, and other metals with ease, even at significant thicknesses.

- Signage Production: Craft custom signs, plaques, and nameplates with precise lettering and graphics.

- Jewelry Making: Engrave intricate patterns on precious metals to create unique pieces.

If you’re looking to diversify your capabilities or improve the quality of your output, a laser cutter CO2 is a must-have tool. Its adaptability ensures it can grow with your business needs.

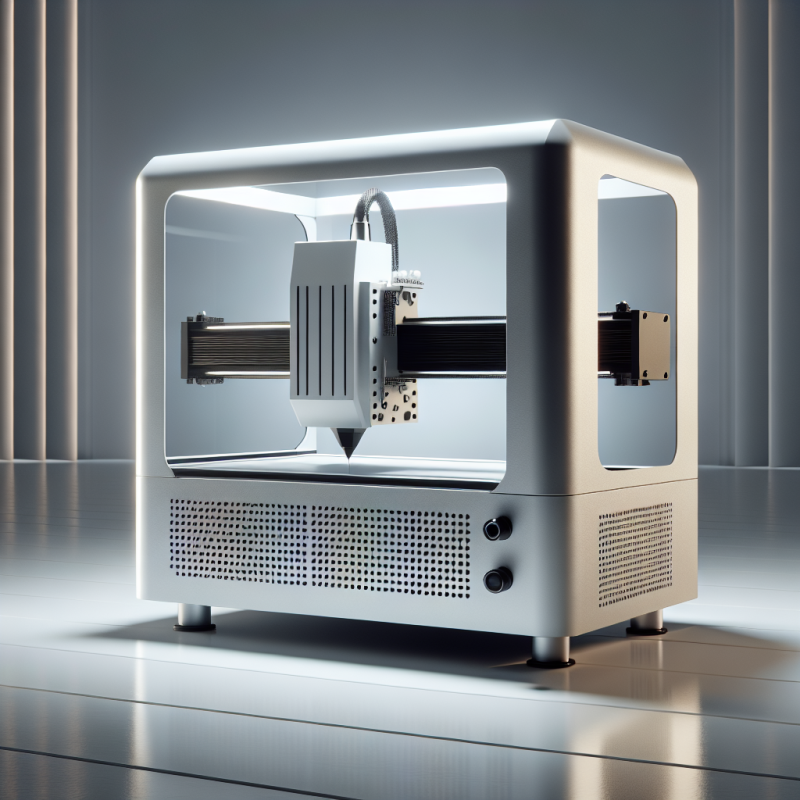

How to Choose the Right Laser Cutter CO2?

Selecting the right laser cutter CO2 depends on several factors:

- Material Thickness: Determine the maximum thickness of the materials you’ll be working with to choose an appropriately powered laser.

- Cutting Speed: Consider how quickly you need to complete tasks, as higher-powered lasers offer faster cutting speeds.

- Budget: Balance your budget with the features and performance level required for your projects.

Remember, investing in a high-quality laser cutter CO2 is a long-term decision that can significantly enhance your productivity and profitability. Take the time to research different models and read reviews to find the best fit for your needs.

Maintenance and Safety Tips

Like any precision tool, proper maintenance and safety protocols are crucial when using a laser cutter CO2:

- Regular Cleaning: Keep the optics and mirrors free from dust to ensure optimal performance.

- Gas Management: Monitor and replace the CO2 gas as needed to maintain laser efficiency.

- Safety Gear: Always wear protective eyewear, gloves, and clothing when operating the machine.

- Ventilation: Ensure proper ventilation to avoid inhaling fumes generated during cutting.

By following these guidelines, you can maximize the lifespan of your laser cutter CO2 while ensuring a safe working environment.

Frequently Asked Questions

1. Can a laser cutter CO2 be used for non-metal materials?

Yes, it can cut and engrave various materials like wood, plastic, and glass with the right settings. However, metal cutting requires higher power levels compared to softer materials.

2. Is a laser cutter CO2 suitable for small-scale projects?

Absolutely! Its precision makes it ideal for custom or small-batch production, ensuring high-quality results every time.

3. How long does a CO2 laser tube last?

The lifespan of a CO2 laser tube typically ranges from 10,000 to 20,000 hours, depending on usage and maintenance. Regular cleaning and gas refills can extend its life.

4. Can I upgrade my current machine with a laser cutter CO2?

Yes, many machines are designed to be compatible with laser cutting technology. Check your manufacturer’s specifications for compatibility details.

Conclusion

The laser cutter CO2 is more than just a tool; it’s a game-changer in the world of manufacturing and craftsmanship. Its ability to deliver precise, high-quality cuts on various materials makes it indispensable for professionals and hobbyists alike. Whether you’re working on custom projects or large-scale production, investing in a laser cutter CO2 can elevate your work to new heights.

If you’re ready to take your craftsmanship to the next level, consider exploring the options available in laser cutting technology. With careful selection and proper maintenance, a laser cutter CO2 will serve as a reliable partner for years to come.