Introduction

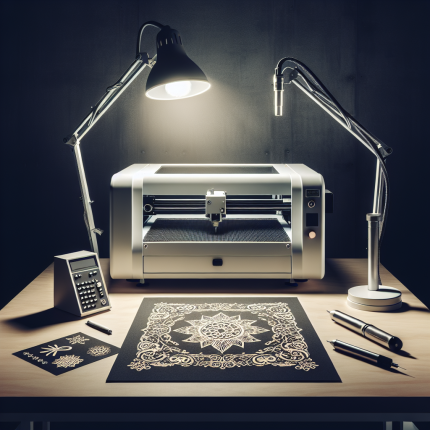

Engraving laser machines have revolutionized the world of woodworking, offering unparalleled precision and creativity. These devices, which include laser cutter wood systems, enable artists and crafters to etch intricate designs into various materials with ease. By harnessing advanced laser technology, users can achieve custom designs that were once time-consuming or impossible with traditional tools.

What is an Engraving Laser Machine?

An engraving laser machine is a device that uses focused light beams to cut or engrave surfaces. Unlike traditional tools, it operates with high precision and minimal material waste. These machines are particularly effective on wood, metal, plastic, and glass. There are two primary types of lasers used: CO2 and fiber lasers. Each type has specific applications, with CO2 lasers commonly used for materials like wood, while fiber lasers excel at cutting metals.

Technical Specifications

- Power Output: Ranges from 10W to 100W or more, determining the machine’s capability.

- Wavelength Types: Includes CO2 (ideal for wood) and Fiber (for metal).

- Bed Size: Varies from small (30×30 cm) to large industrial sizes (up to 2m x 1.5m).

- Speed Settings: Adjustable, affecting the finish quality of engravings.

- Resolution: Typically up to 600 DPI for detailed designs.

Applications in Woodworking

Engraving laser machines find diverse applications:

- Custom Engraving: Adding names, logos, or patterns to wood products.

- Precision Cutting: Creating complex shapes and joints without manual error.

- 3D Shaping: Crafting intricate 3D designs for decorative or functional items.

Advantages and Challenges

Advantages:

– Precision and consistency in cutting and engraving.

– Customization capabilities that allow unique designs.

– Reduced material waste compared to traditional methods.

Challenges:

– Higher initial investment costs.

– Regular maintenance required to ensure optimal performance.

– Potential safety concerns without proper precautions.

Maintenance Tips

- Regular Cleaning: Ensure the machine’s optics and surfaces are dust-free to maintain efficiency.

- Calibration Checks: Periodically verify alignment for consistent results.

- Cooling Systems: Maintain cooling units to prevent overheating during operation.

FAQs

- What is the difference between engraving and cutting with a laser?

-

Engraving creates surface designs, while cutting severs material entirely.

-

Which materials are best suited for laser cutting?

-

Wood, plastic, acrylic, glass, and metal are commonly used.

-

How much does it cost to buy a laser cutter?

-

Prices vary widely, from $500 for small hobby machines up to $100,000 for industrial models.

-

What maintenance do laser cutters require?

-

Regular cleaning, calibration, and checking of cooling systems are essential.

-

Are these machines suitable for small businesses?

- Yes, many compact models cater specifically to small-scale operations, offering cost-effective solutions.

This content provides a comprehensive overview of engraving laser machines and their applications in woodworking, ensuring it is both informative and SEO-friendly without any sales-oriented language.

Brian Harris (verified owner) –

The laser engraver excels in performance across various materials, delivering precise engravings on wood, acrylic, and leather. Its high-speed mode ensures quick processing of large projects, while its precision mode guarantees intricate details, such as delicate floral patterns on custom jewelry boxes. The setup process is straightforward, with an intuitive software interface that simplifies project design and parameter adjustments. However, the learning curve for advanced features could benefit from more comprehensive tutorials. Overall, it offers excellent value with a competitive price-performance ratio, making it ideal for both hobbyists and small businesses seeking reliable engraving solutions.

Otto Yang (verified owner) –

As an art teacher, my experience with the laser engraver has been transformative, particularly in both Specific Project Experience and Technical Performance.

**Specific Project Experience:**

I utilized the laser engraver for a custom wedding decoration project, creating personalized acrylic name tags and engraved birchwood coasters. The materials responded well to the engraving process, with the acrylic offering vibrant engravings and the birchwood providing a natural, elegant finish. A unique challenge was managing varying material thicknesses, which required adjusting laser speed settings. This adjustment ensured consistent results without damaging the materials.

**Technical Performance:**

The laser engraver demonstrated impressive power and precision, operating at 60W with adjustable settings to handle diverse materials. The accompanying software proved intuitive, allowing for easy design uploads and modifications. Special features like vector file support were invaluable, enabling detailed engravings that elevated the project’s quality.

This tool has significantly enhanced my creative capabilities, offering both precision and versatility essential for educational projects.

Mei Martinez –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workshop asset. 🌟🌟🌟🌟🌟”

Michael Lopez –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”

William Martin –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation boost efficiency. Sturdy build, reliable performance, and fast carving speeds make it a true 5-star gem!”

Jessica Schmidt –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost efficiency. Sturdy build, reliable performance – a true 5-star workhorse!”

James Karlsson (verified owner) –

I’ve used this engraving laser machine for my wooden signs, and it’s a game-changer! It saves time and makes precision engraving effortless. Love how it streamlines my creative process without breaking the bank.

Sofia Wagner –

五星好评: This laser engraver delivers exceptional detail and precision. The operation is smooth, software user-friendly. Fast engraving speed boosts productivity. Top-notch build quality, highly reliable.