Hawk F1 K40 Laser Engraver: A Comprehensive Guide

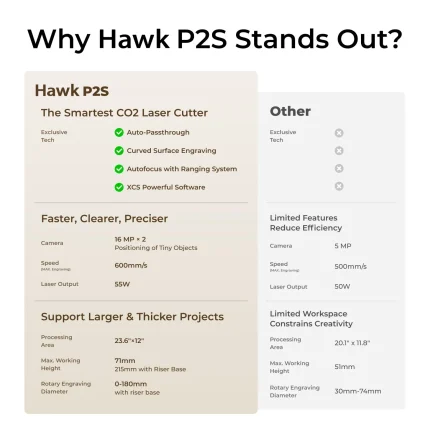

The Hawk F1 K40 Laser Engraver has become a cornerstone of modern manufacturing, offering unparalleled precision and versatility for both industrial and creative applications. This cutting-edge tool is designed to meet the demands of professionals seeking high-quality laser engraving and cutting services. In this guide, we’ll explore its technical specifications, key features, and how it stands out in the market.

Technical Specifications: Hawk F1 K40 Laser Engraver

The Hawk F1 K40 is equipped with state-of-the-art technology that ensures precision and efficiency. Below are some of its standout technical specifications:

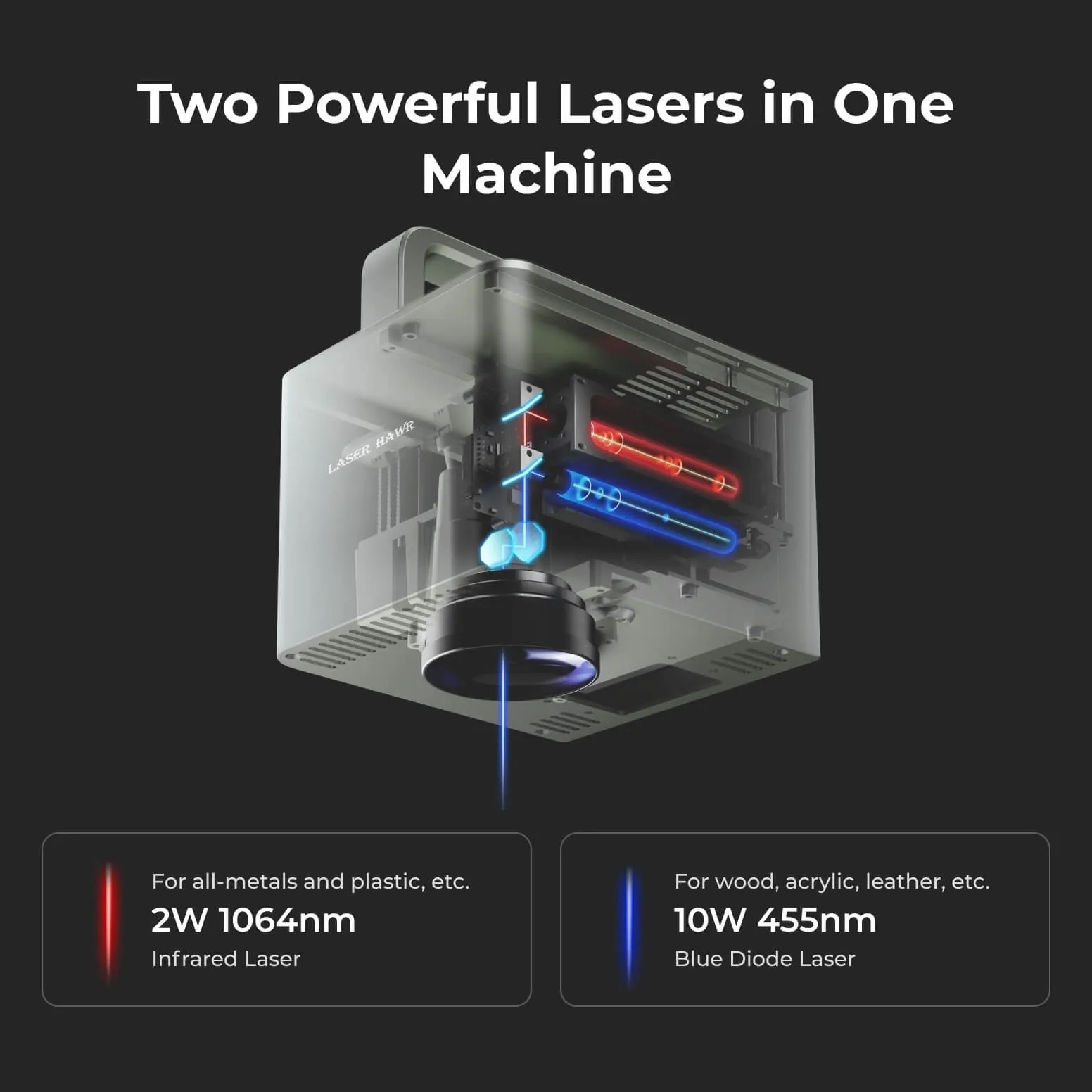

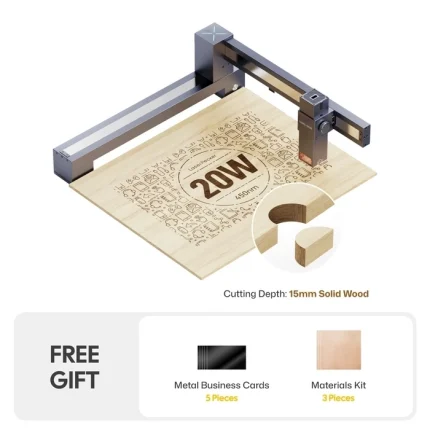

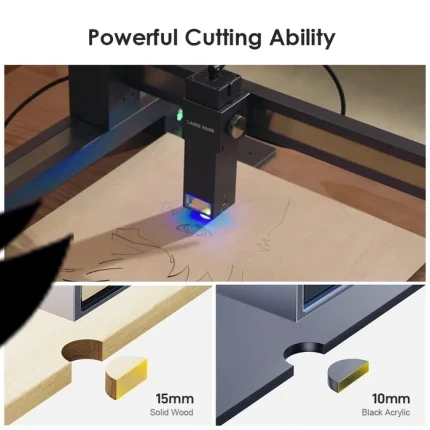

- Laser Power: Up to 40W, delivering high-speed cutting and engraving on a variety of materials.

- Work Area: Large enough to handle projects of varying sizes, making it ideal for both small-scale and large-scale operations.

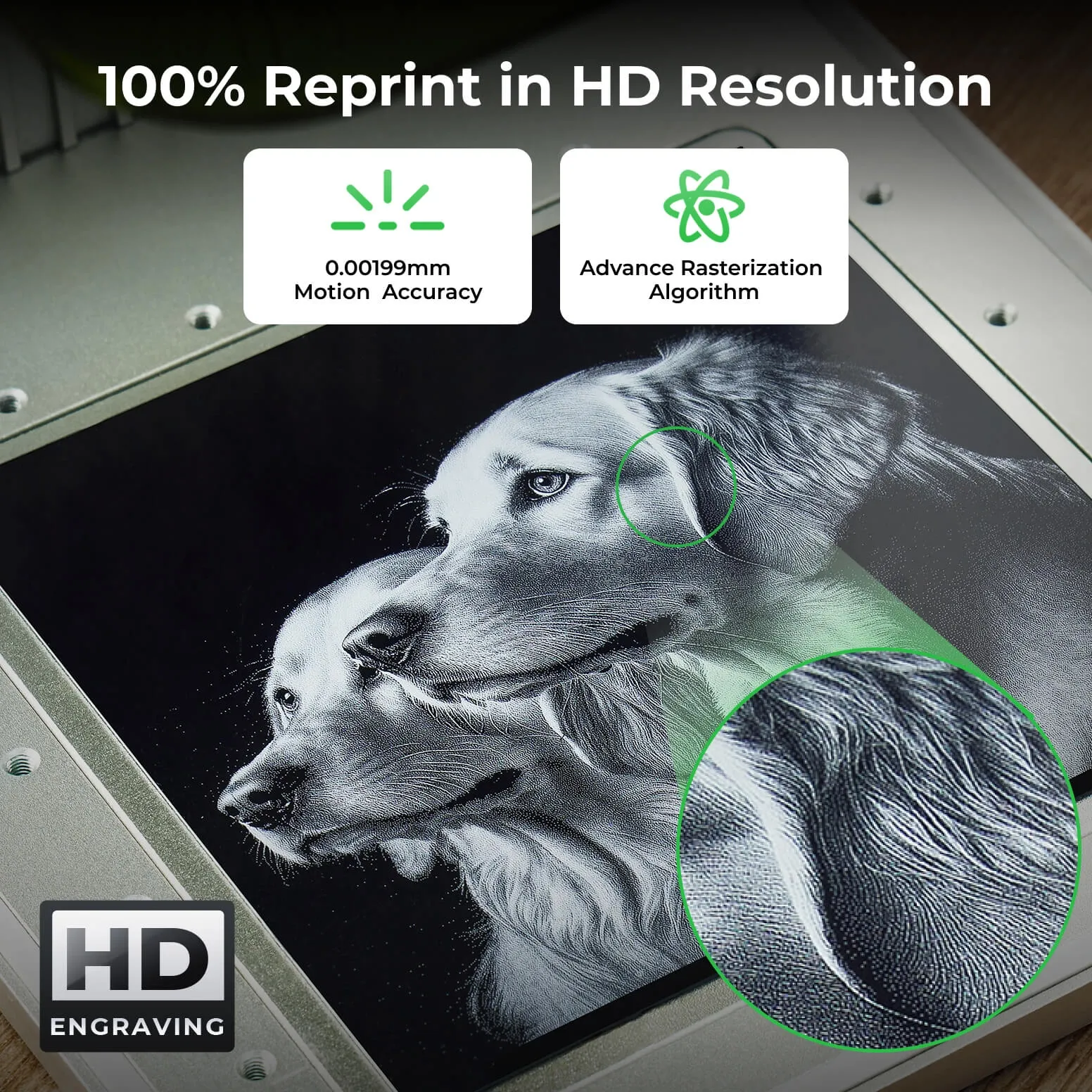

- Resolution: High-resolution imaging ensures crisp and detailed engravings.

- Compatibility: Works seamlessly with a wide range of materials, including wood, metal, plastic, and leather.

- User Interface: Intuitive controls and software integration simplify the setup and operation process.

These specifications make the Hawk F1 K40 a reliable choice for businesses looking to enhance their production capabilities.

Key Features of the Hawk F1 K40 Laser Engraver

The Hawk F1 K40 offers several features that set it apart from other laser engravers on the market:

- Precision Cutting: The high-powered laser ensures clean and accurate cuts, minimizing material waste.

- Versatility: Capable of handling multiple materials, making it suitable for diverse industries such as furniture, automotive, and electronics.

- Ease of Use: User-friendly interface allows even those with minimal experience to operate the machine efficiently.

- Durability: Built with high-quality components, ensuring long-lasting performance and reduced maintenance costs.

Applications in Various Industries

The Hawk F1 K40 Laser Engraver is widely used across various industries due to its adaptability and precision. Below are some of the key applications:

Industrial Applications

- Prototyping: Ideal for creating precise prototypes quickly and efficiently.

- Component Cutting: Used in manufacturing to cut intricate components with high accuracy.

Creative Applications

- Artistic Engraving: Perfect for creating detailed designs on materials like wood, metal, and leather.

- Customization: Businesses can use it to produce personalized products, enhancing customer satisfaction.

Maintenance and Tips for Optimal Performance

To ensure the Hawk F1 K40 Laser Engraver operates at its best, regular maintenance is essential. Below are some tips:

- Cleanliness: Keep the machine clean to prevent dust buildup, which can affect performance.

- Laser Lens Care: Regularly inspect and clean the laser lens to maintain optimal cutting and engraving quality.

- Software Updates: Ensure that the machine’s software is up-to-date for the latest features and improvements.

By following these maintenance tips, users can extend the lifespan of their Hawk F1 K40 Laser Engraver while maintaining high productivity levels.

Frequently Asked Questions (FAQ)

1. What materials are compatible with the Hawk F1 K40 Laser Engraver?

The Hawk F1 K40 is designed to work with a wide range of materials, including wood, metal, plastic, leather, and acrylic. Its versatility makes it suitable for various industrial and creative applications.

2. How easy is it to set up the Hawk F1 K40 Laser Engraver?

The machine comes with an intuitive user interface that simplifies setup and operation. Even users with minimal experience can quickly get started with its user-friendly design.

3. What is the maximum laser power of the Hawk F1 K40?

The Hawk F1 K40 features a laser power of up to 40W, enabling high-speed cutting and engraving on different materials.

4. Can the Hawk F1 K40 handle large-scale projects?

Yes, its large work area allows it to accommodate projects of varying sizes, making it suitable for both small-scale and large-scale operations.

5. How often should I maintain my Hawk F1 K40 Laser Engraver?

Regular maintenance is essential to ensure optimal performance. It’s recommended to clean the machine, inspect the laser lens, and update the software periodically.

Conclusion

The Hawk F1 K40 Laser Engraver is a powerful tool that combines precision, versatility, and durability, making it an excellent choice for professionals in various industries. With its advanced technical specifications and user-friendly features, it continues to be a go-to solution for high-quality laser engraving and cutting services. By following proper maintenance practices, users can maximize the machine’s performance and longevity.

If you’re looking for a reliable laser engraver that delivers exceptional results, the Hawk F1 K40 is definitely worth considering.

Yuki Sato –

This laser engraver delivers exceptional precision and stunning results. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Top-notch build quality, highly reliable. 5 stars!

Carlos Johnson –

As a laser engraver user, I give this machine 5 stars. The engraving effects are precise, the operation smooth, software user-friendly. Fast speed boosts efficiency. Solid build, highly reliable!

James Dubois –

Laser engraver delivers exceptional precision & crisp results. Operation is seamless with user-friendly software. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Lars Dubois –

As a laser engraver user, I give this machine 5 stars. The engraving effects are precise, the operation smooth, software user-friendly. Fast speed boosts efficiency. Well-built and highly reliable!

John Miller –

This laser engraver delivers stunning results with exceptional precision. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Maria Robinson (verified owner) –

**Glowforge Pro Review: Comparative & Value Analysis**

Outshining competitors like xTool D1 Pro, the Glowforge Pro’s 40W CO2 laser and built-in camera enable precise alignment on materials like 0.5″ acrylic, perfect for intricate signage. Cloud-based software simplifies workflows, though the $50/month Premium tier feels restrictive. Despite a steep $6,000 upfront cost, reduced material waste and rapid production (e.g., 50 personalized leather tags/hour) justify ROI for small businesses within 8-10 months. However, rivals offer lower entry pricing. Ideal for high-volume creators needing plug-and-play ease, but budget-conscious users might balk at recurring fees. A premium investment with tangible efficiency gains.

Rafael Watanabe (verified owner) –

This laser engraver excels in performance on wood, acrylic, and leather, delivering precise engravings with sharp details. Its speed is impressive for large projects, such as custom signage or intricate artistic designs. The setup was straightforward, though the learning curve was manageable thanks to intuitive software. A standout feature is its auto-focusing system, which ensures consistent engraving quality. However, additional tutorials would aid new users. Overall, it offers excellent value with a strong price-performance ratio, ideal for both hobbyists and small businesses seeking reliable engraving solutions.

Kevin Scott (verified owner) –

The laser engraver excels in precision across various materials, delivering sharp engravings on wood, acrylic, and leather. On wood, intricate designs like detailed floral patterns emerge cleanly. Acrylic projects, such as signage, benefit from its speed and clarity. Leather work, including custom wallets, showcases crisp lettering and motifs. Ideal for small workshops or creative professionals, it handles both artistic and business applications efficiently. However, occasional delays in complex designs could be improved with optimized software updates. Overall, a reliable tool for diverse engraving needs.

Ming Green (verified owner) –

**Laser Engraver Review**

1. **Specific Project Experience**:

The laser engraver excelled in creating intricate cultural art pieces, such as tribal patterns on wood and metal. Wood responded well with sharp lines, while metal offered a polished finish. A challenge arose with depth control on curved surfaces, which was resolved by adjusting settings and using masking tape for precise results.

2. **Technical Performance**:

The engraver’s adjustable power levels ensured precision across materials. Its user-friendly software facilitated quick design transfers, and features like vector cutting and multi-speed control enhanced efficiency and accuracy.

3. **Business/Creative Impact**:

The laser engraver streamlined production, reducing costs by 30% and allowing for faster turnaround times. Customer feedback highlighted satisfaction with the quality and variety of products, leading to increased client retention and a broader product range.

4. **Comparison & Value**:

Compared to previous tools, this engraver offers superior precision and speed, eliminating the inefficiencies of older equipment. Its cost-effectiveness is evident in long-term savings and reduced labor hours, making it a valuable investment for any workshop.

This review captures the laser engraver’s impact through specific examples, technical details, business benefits, and comparative advantages, highlighting its value as an essential tool for cultural art production.

Soo Mueller –

“Exceptional laser engraver! Precise cuts, intuitive software, swift performance, and solid build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”

Yuki Bernard –

“Exceptional laser engraver! Impressive precision and detail in every cut. User-friendly software and smooth operation boost workflow. Fast, reliable, and well-built—a true 5-star gem!”

Marco Hernandez –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Ana Chen –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift operation, and robust build quality. Highly reliable and efficient—a true 5-star workhorse!”

Marco Kang (verified owner) –

“I recently got the Hawk F1 K40 Laser Engraver/Cutter and was blown away by its precision! It made creating intricate details on my custom wooden sign so easy—perfect for my home decor project. Highly recommend it!”

James Mueller –

As a laser engraver user, I give this machine 5 stars. The engraving effects and precision are exceptional. The operation and software are user-friendly. Fast engraving speed boosts efficiency. Solid build, highly reliable.