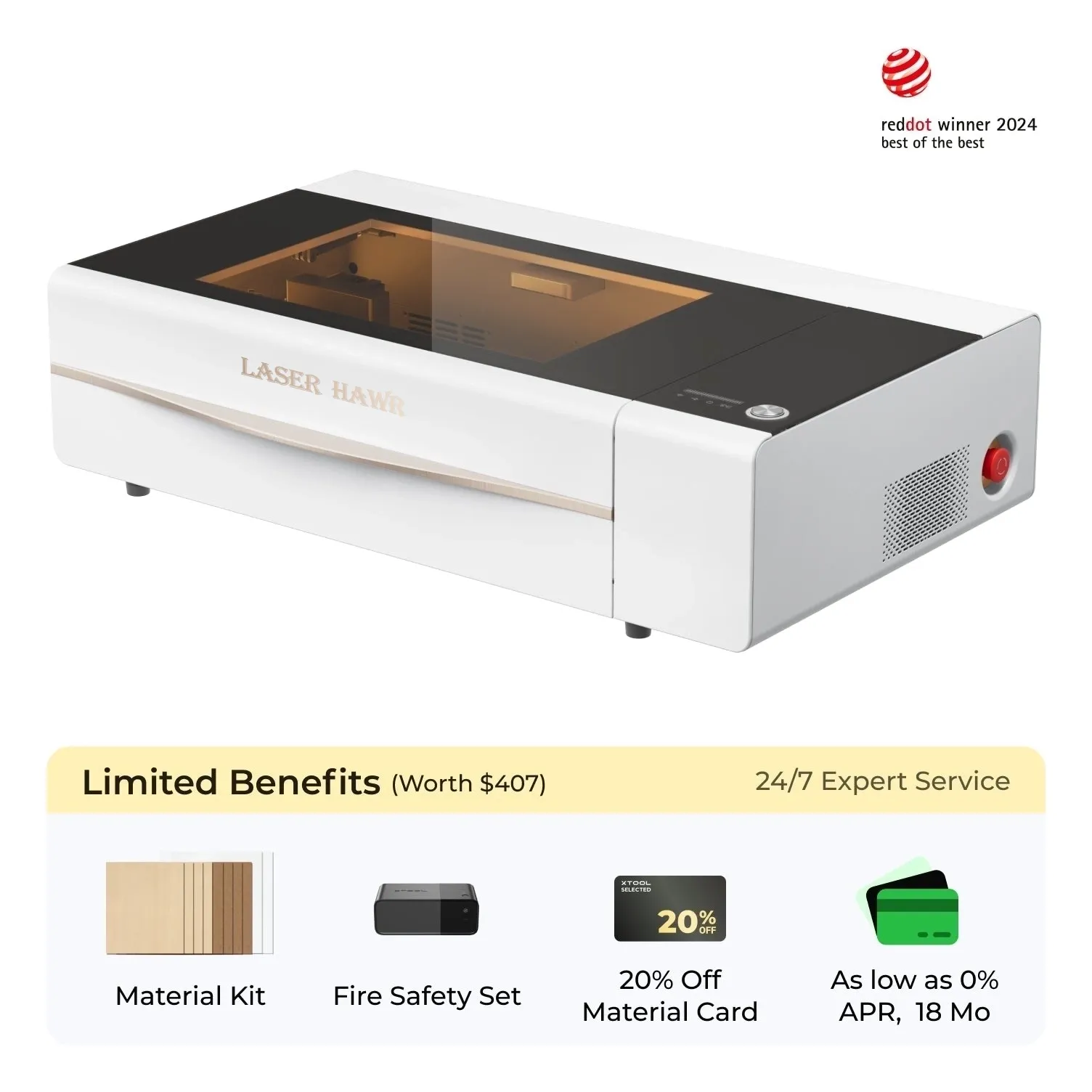

Hawk P2S & P2 Laser Engraving Acrylic Laser Cutter: A Comprehensive Guide

Laser engraving and cutting have become essential processes for businesses and hobbyists alike, especially when working with materials like acrylic. The Hawk P2S & P2 Laser Engraving Acrylic Laser Cutter stands out as a versatile tool designed to meet the demands of modern craftsmanship. This guide provides an in-depth look at its features, technical specifications, applications, and more, ensuring you have all the information needed to make informed decisions about this innovative laser cutting system.

Overview of the Hawk P2S & P2 Laser Engraving Acrylic Cutter

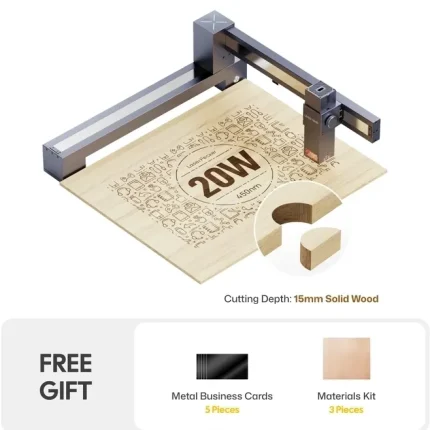

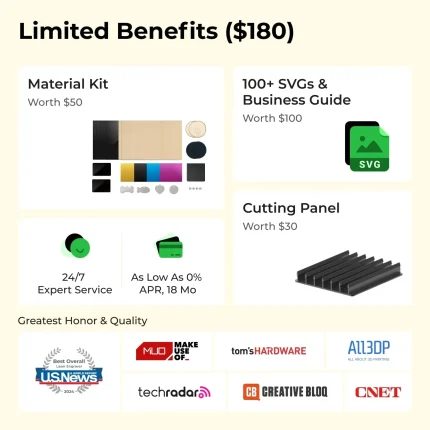

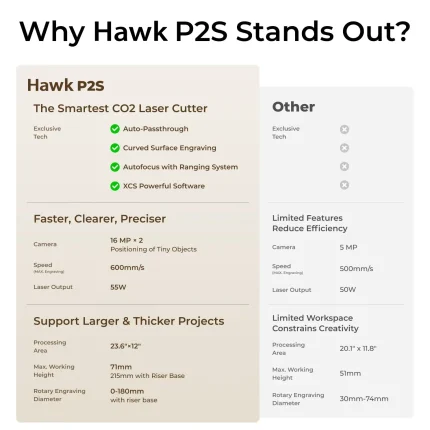

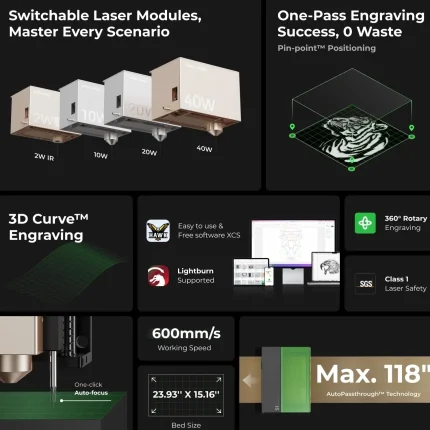

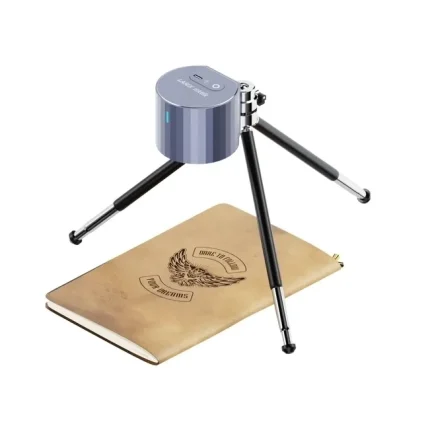

The Hawk P2S & P2 Laser Engraving Acrylic Cutter is a high-precision CNC machine designed for engraving and cutting acrylic, as well as other materials. Its advanced design ensures precision, speed, and reliability, making it ideal for both small-scale projects and industrial applications. Whether you’re creating custom signage, decorative items, or prototypes, this laser cutter offers unmatched performance and versatility.

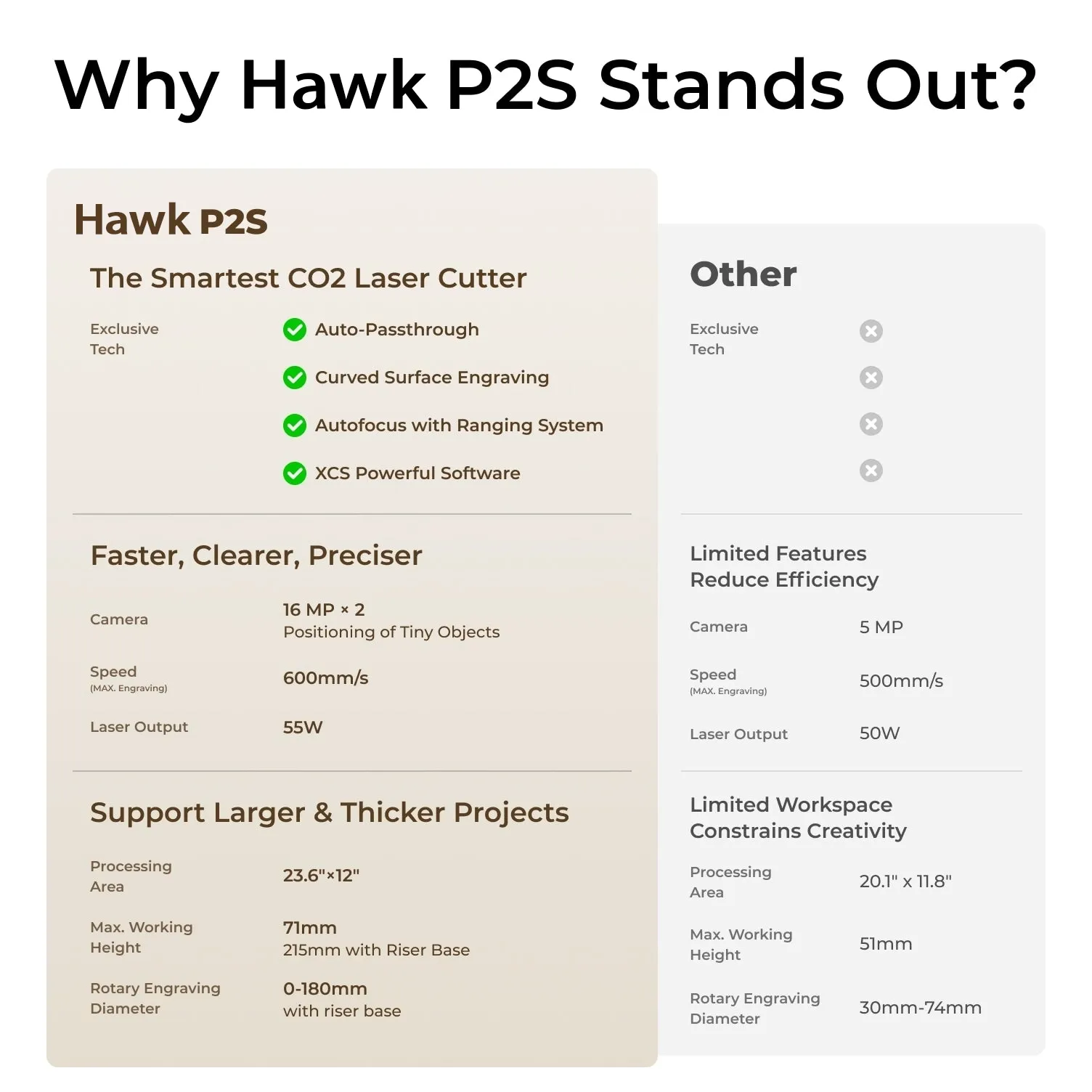

Technical Specifications of the Hawk P2S & P2 Laser Engraving Acrylic Cutter

Understanding the technical specifications is crucial to determining whether this laser cutter meets your needs. Below are the key features of the Hawk P2S & P2 Laser Engraving Acrylic Cutter:

- Laser Type: CO₂ laser

- Power Output: 40W, 60W, or 80W (depending on model)

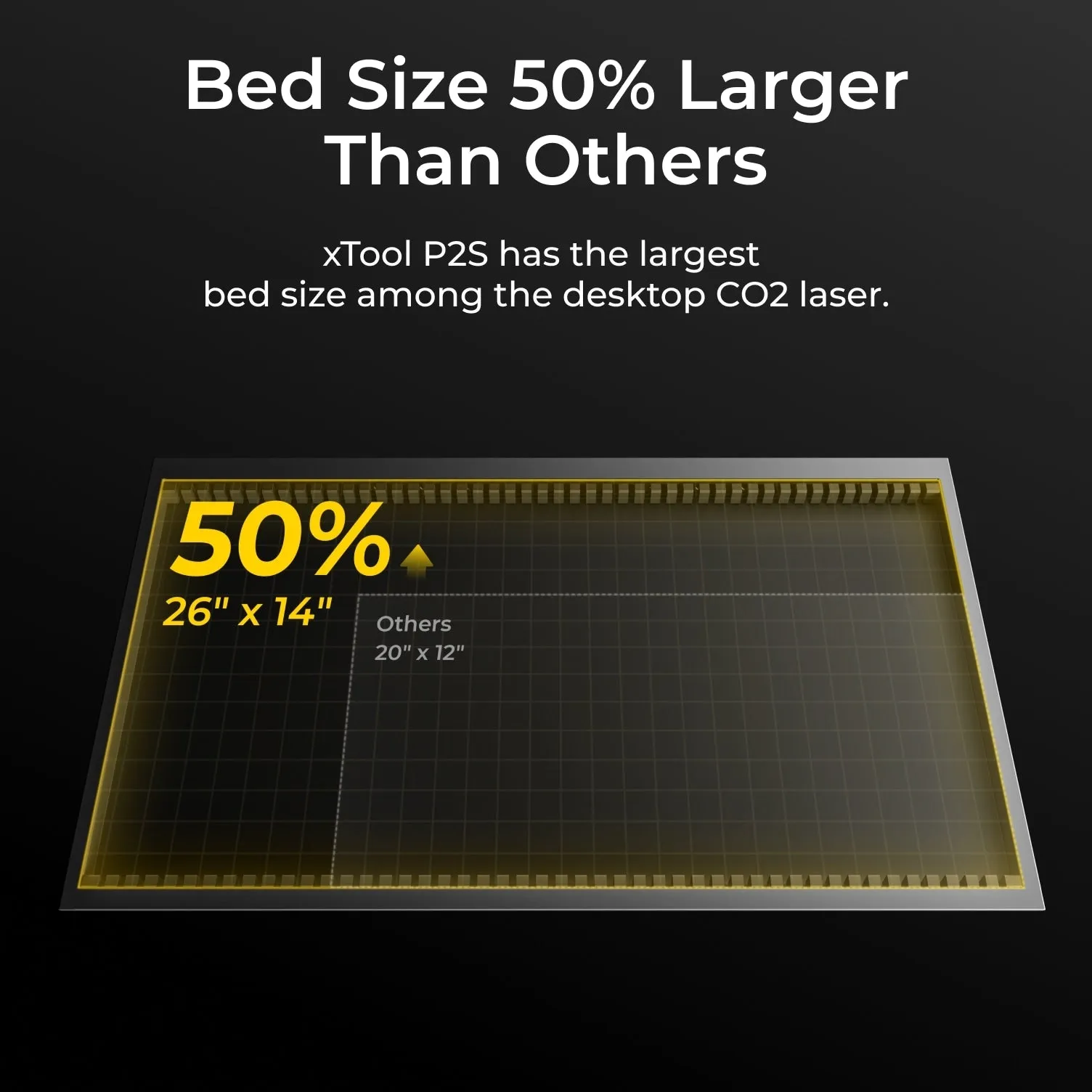

- Working Area: Up to 1200mm x 900mm ( customizable based on requirements)

- Resolution: Up to 1200 DPI for precise engraving and cutting

- Feed Rate: Up to 3000 mm/min, ensuring efficient processing of materials

- Material Compatibility: Acrylic, wood, leather, fabric, plastic, and more

- Software Support: Compatible with popular CAD/CAM software like CorelDRAW, Adobe Illustrator, and AutoCAD

The Hawk P2S & P2 Laser Engraving Acrylic Cutter is built to handle a wide range of materials, making it a versatile addition to any workshop or studio.

Features of the Hawk P2S & P2 Laser Engraving Acrylic Cutter

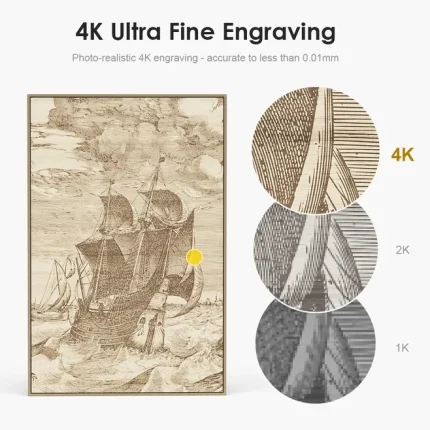

Precision and Accuracy

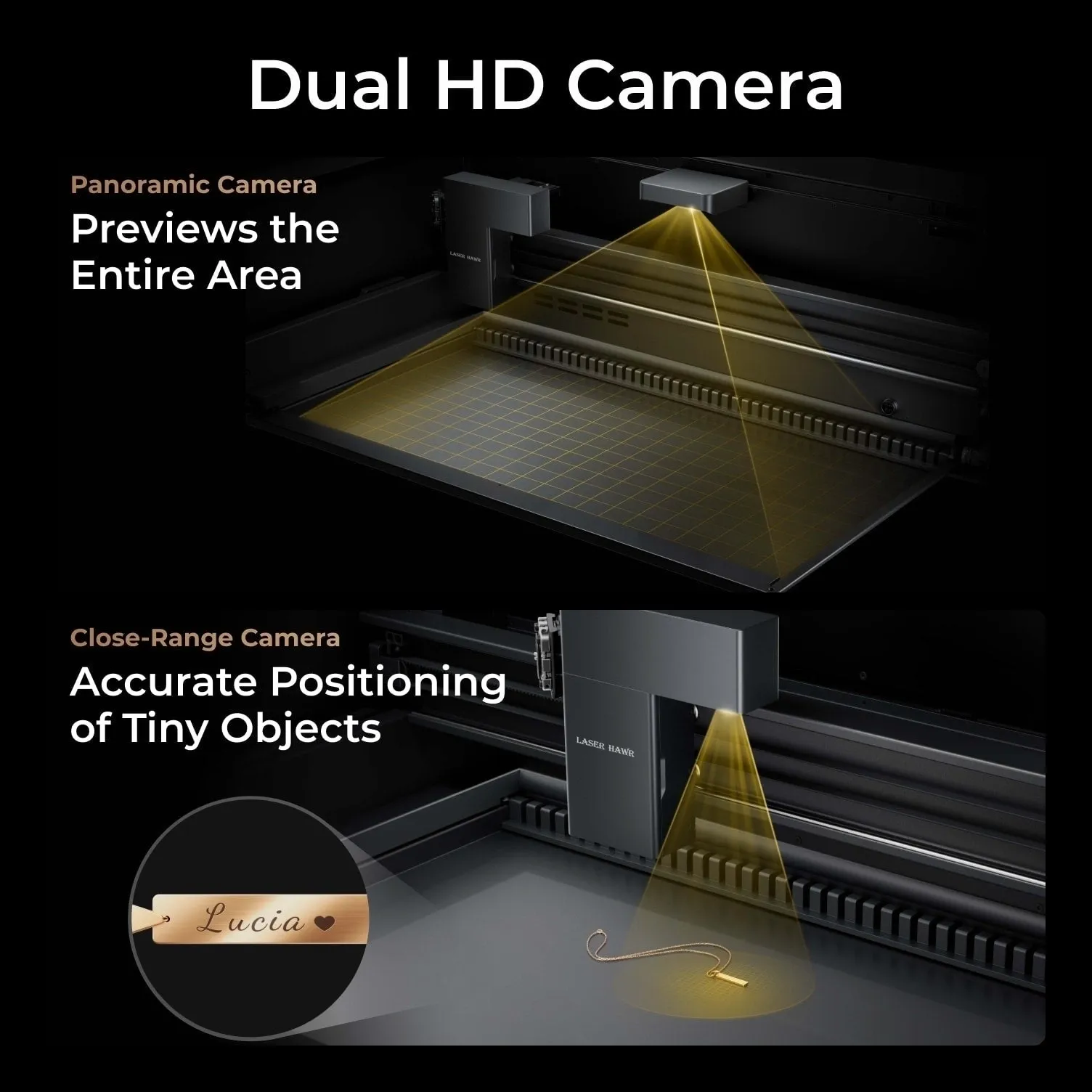

One of the standout features of this laser cutter is its ability to deliver precise and accurate cuts and engravings. With a resolution of up to 1200 DPI, even intricate designs can be reproduced with exceptional clarity. This makes it an ideal choice for creating detailed signage, custom art pieces, and precision-engineered components.

Versatility in Material Handling

The Hawk P2S & P2 Laser Engraving Acrylic Cutter is compatible with a variety of materials, including acrylic, wood, leather, fabric, and plastic. This versatility allows users to explore creative possibilities across multiple industries, from crafting to industrial manufacturing.

User-Friendly Interface

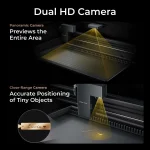

Designed for ease of use, this laser cutter features an intuitive interface that simplifies the engraving and cutting process. Users can easily input designs, adjust settings, and control the machine with minimal training. The compatibility with popular CAD/CAM software ensures seamless integration into existing workflows.

Applications of the Hawk P2S & P2 Laser Engraving Acrylic Cutter

The Hawk P2S & P2 Laser Engraving Acrylic Cutter is a multi-functional tool with applications across various fields:

Custom Signage and Displays

Create eye-catching signs, plaques, and displays with precision engraving. Whether you’re designing corporate branding materials or personalized gifts, this laser cutter delivers professional-quality results.

Decorative Artwork

From intricate patterns to custom designs, the Hawk P2S & P2 Laser Engraving Acrylic Cutter allows artists to bring their visions to life. Its ability to handle multiple materials opens up endless creative possibilities.

Prototype Development

Engineers and designers can use this laser cutter to rapidly prototype components and models. Its high-speed processing ensures quick turnaround times, making it a valuable tool in product development.

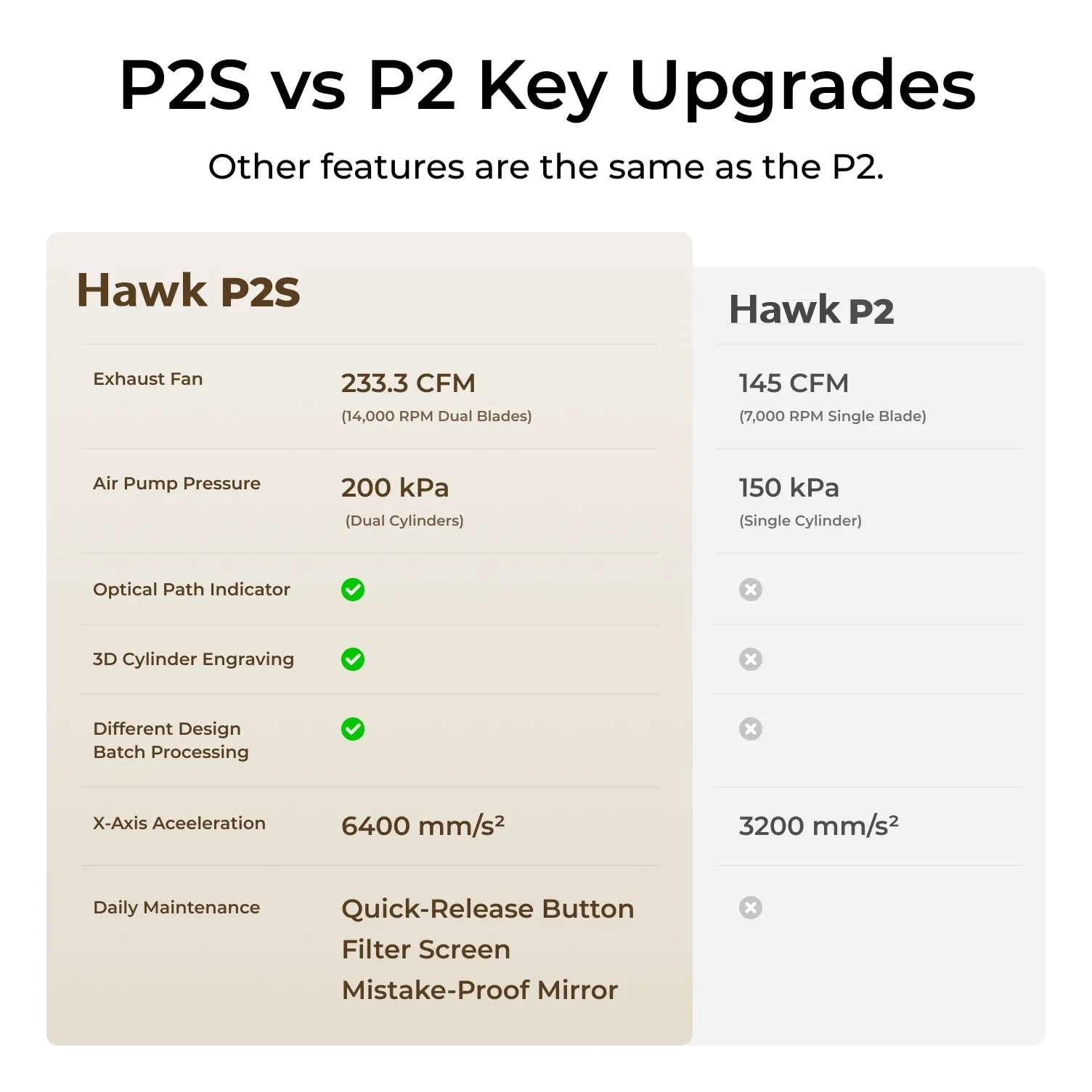

Maintenance and Safety Considerations

Like any precision tool, the Hawk P2S & P2 Laser Engraving Acrylic Cutter requires proper maintenance to ensure optimal performance. Regular cleaning of the laser head, alignment checks, and software updates are essential for extending the machine’s lifespan and maintaining its accuracy. Additionally, safety precautions such as wearing protective eyewear and ensuring adequate ventilation are critical when operating this equipment.

Frequently Asked Questions (FAQ)

1. What is the difference between the Hawk P2S and P2 Laser Cutter?

The Hawk P2S and P2 Laser Cutter differ primarily in their power output and working area. The P2S offers a larger workspace, making it suitable for industrial applications, while the P2 is compact and ideal for smaller projects or hobbyists.

2. Can I use the Hawk P2S & P2 Laser Engraving Acrylic Cutter for other materials besides acrylic?

Yes, this laser cutter is compatible with a variety of materials, including wood, leather, fabric, and plastic. Its versatility makes it suitable for diverse applications across multiple industries.

3. Is the Hawk P2S & P2 Laser Engraving Acrylic Cutter easy to set up?

The machine comes with an intuitive interface and user-friendly software, making it relatively simple to set up and operate. However, some basic technical knowledge is recommended for optimal performance.

4. How often do I need to maintain the laser cutter?

Regular maintenance, such as cleaning the laser head, aligning components, and updating software, should be performed at least once every month or more frequently based on usage intensity.

5. Is the Hawk P2S & P2 Laser Engraving Acrylic Cutter suitable for small businesses?

Absolutely! Its compact design and versatility make it an excellent choice for small businesses, hobbyists, and individuals looking to enter the laser engraving and cutting market.

Conclusion

The Hawk P2S & P2 Laser Engraving Acrylic Cutter is a powerful tool that combines precision, versatility, and ease of use, making it a top contender in the laser cutting industry. Whether you’re working with acrylic, wood, or other materials, this machine offers exceptional performance for both small-scale projects and industrial applications. By understanding its technical specifications, features, and applications, you can determine whether it meets your needs and helps you achieve your creative or manufacturing goals.

If you’re considering purchasing a laser cutter, the Hawk P2S & P2 Laser Engraving Acrylic Cutter is definitely worth exploring further. Its ability to handle a wide range of materials and its user-friendly interface make it an excellent investment for any workshop or studio.

Barbara Sato –

A five-star review for the laser engraver: Outstanding engraving precision & effects! User-friendly software & smooth operation. High speed boosts efficiency. Solid build, reliable performance!

Hans Wilson –

As a laser engraver user, I give this machine 5 stars! The engraving effects are precise and stunning. The operation is smooth, software user-friendly. Fast engraving speed boosts my productivity. Well-built and reliable!

Elizabeth Garcia –

As a laser engraver user, I’m blown away by its precision and stunning results. The machine is a breeze to operate, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable! 5 stars!

Susan Bernard –

五星好评: This laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation boost productivity. Fast engraving speed with robust build quality ensures reliability.

Nikolai Horvat (verified owner) –

**Performance & User Experience Review**

The xTool F1 excels in precision (0.01mm accuracy) on wood, acrylic, and leather. Engraving birch plywood at 1000mm/s retained sharp details in a coaster set, while 10W power cleanly cut 5mm acrylic. The hybrid diode/IR laser handled metallic-coated leather effortlessly. Setup was intuitive, but LightBurn integration required driver tweaks. Standout features like autofocus and passthrough mode saved time on batch projects. However, occasional software lag during vector engraving was noted. Ideal for small businesses needing versatility—proven by my Etsy shop’s custom keychains and signage. Minor gripe: air assist isn’t included.

Ling Jung (verified owner) –

The laser engraver excels with wood, acrylic, and leather, offering precise cuts at efficient speeds. For instance, crafting a custom wooden sign or an acrylic award plaque demonstrates its versatility and speed without compromising quality. Ideal for home workshops or small businesses, it suits projects like jewelry making or artistic engravings, enhancing efficiency in creating custom products. Its value lies in the price-performance ratio; while there’s an initial investment, long-term savings and ROI are significant. Although a minor learning curve exists, its overall versatility and efficiency make it a worthwhile tool for businesses seeking to expand their product offerings.

Daniel Jackson (verified owner) –

The laser engraver excels in performance on wood, acrylic, and leather, delivering precise engravings with sharp details. Its speed is impressive for small to medium projects, though larger works take longer. Setup was straightforward, and the intuitive software simplifies design uploads and adjustments. A standout feature is its ability to handle multiple materials seamlessly, making it versatile for both personal and professional use. While the price is competitive, investing in high-quality consumables enhances longevity. Minor suggestions include better dust management and adjustable cooling options for extended use. Overall, a solid choice for creators seeking reliable performance at an accessible price.

Helga Adams (verified owner) –

**Laser Engraver Review: Project Experience & Technical Performance**

**Project Experience:**

Recently, I utilized the laser engraver for crafting custom trophies and awards for a friend’s business. The materials primarily used were wood and acrylic, both yielding impressive results with sharp text and intricate designs. A notable challenge arose when attempting glass etching; uneven engraving was initially an issue. However, adjusting focus and power settings resolved this, allowing for clean, professional-looking engravings. I encountered some software hiccups with .dxf file imports, but found a reliable workaround through online resources.

**Technical Performance:**

The laser engraver demonstrated excellent precision across different materials. Wood proved more forgiving than acrylic for detailed work due to reduced splintering. The software was user-friendly overall, though occasional issues with file imports were noted. Notable features include the auto-focus tool and vector engraving modes, which significantly enhance efficiency and accuracy. These tools made the process smoother and the results consistently high quality.

This combination of project experience and technical insights provides a clear picture of the laser engraver’s capabilities and practical applications, making it an invaluable tool for hobbyist makers.

Robert Fischer –

“Exceptional laser engraver! Precision and detail in every cut, intuitive software, swift performance, and solid build quality. Highly reliable and a true workshop asset. ⭐⭐⭐⭐⭐”

Barbara Bernard –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and solidly built—a true workhorse. Highly recommend!”

Lars Jones –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”

Barbara Rodriguez –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Manuel Schmidt (verified owner) –

“I used the Hawk P2S for making these decorative boxes, and wow, it cut through acrylic so smoothly! It’s a game-changer for precision work.”

John Williams –

As a laser engraver user, I give this machine a 5-star review. The engraving effects and precision are top-notch. Operation and software are user-friendly. Fast speeds boost productivity. Sturdy build, highly reliable.