Hawk S1 Laser Acrylic Cutter & K40 Laser Engraver: A Comprehensive Guide

If you’re looking for high-quality laser cutting and engraving solutions, the Hawk S1 Laser Acrylic Cutter and the K40 Laser Engraver are two of the most popular tools in the market. Both devices are designed to provide precise and efficient results for a wide range of materials, including acrylic, wood, metal, and more. Whether you’re a professional or an amateur hobbyist, these machines offer versatility and reliability that can elevate your projects. In this guide, we’ll explore their technical specifications, features, differences, and use cases to help you make an informed decision.

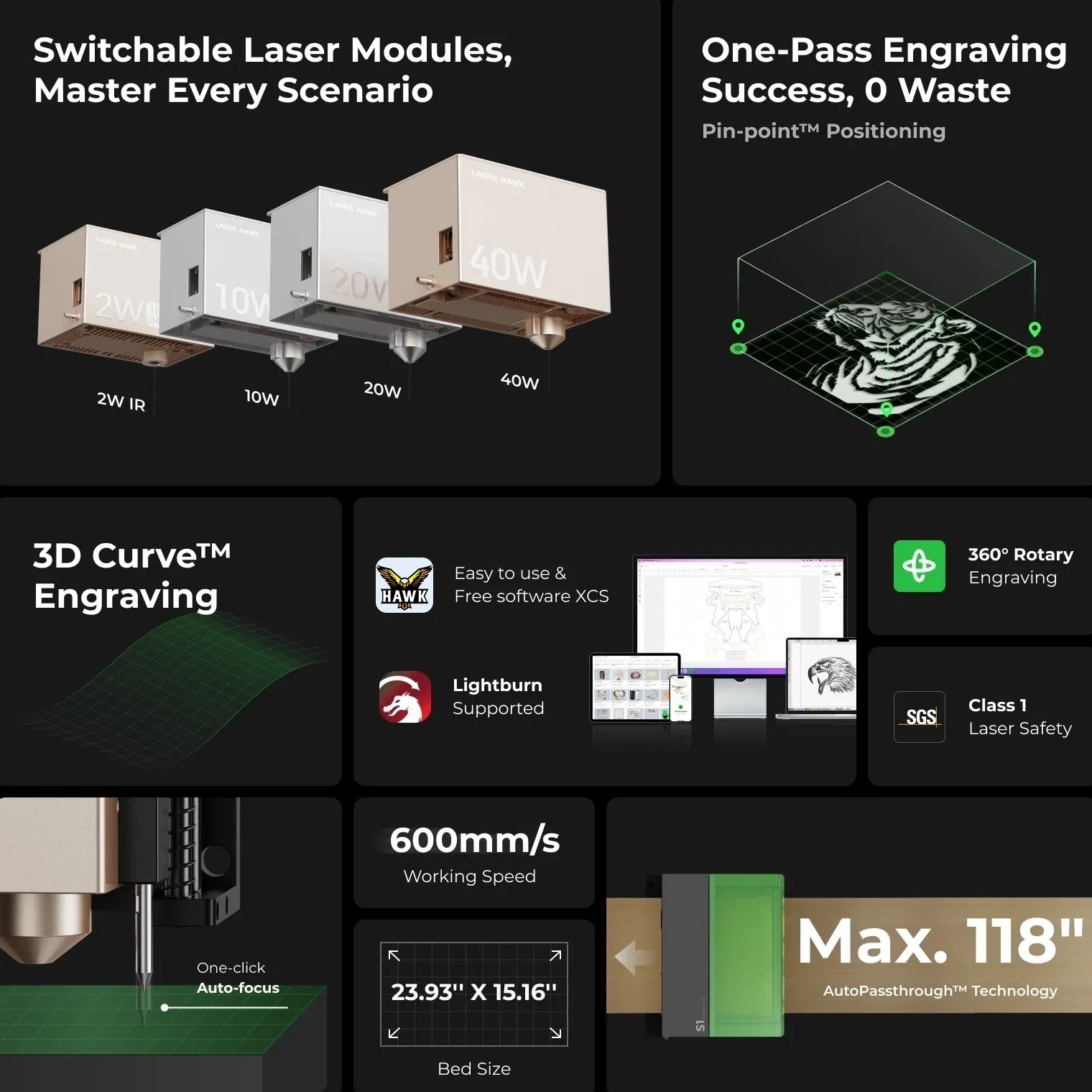

Technical Specifications of the Hawk S1 Laser Acrylic Cutter

The Hawk S1 Laser Acrylic Cutter is a compact yet powerful machine designed for cutting and engraving acrylic sheets with precision. Below are its key technical specifications:

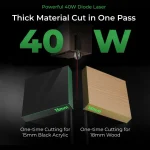

- Laser Power: 40W CO2 laser

- Cutting Speed: Up to 3,000 mm/s (varies based on material thickness)

- Engraving Speed: Up to 1,500 mm/s

- Maximum Working Area: 600mm x 900mm (customizable for larger projects)

- Material Compatibility: Acrylic, wood, leather, plastic, and other non-metallic materials

- Resolution: 1200 DPI for high-quality engravings

- Control Interface: User-friendly software with advanced design tools

Key Features of the Hawk S1 Laser Acrylic Cutter

- Precision Cutting: The Hawk S1 is ideal for cutting intricate designs and shapes in acrylic sheets.

- Versatile Engraving: Capable of creating detailed engravings on various materials, including wood and leather.

- Easy Setup: Designed for quick installation and setup with minimal hassle.

- Durability: Built with high-quality components to ensure long-lasting performance.

Technical Specifications of the K40 Laser Engraver

The K40 Laser Engraver is another popular machine known for its versatility and affordability. Here are its technical specifications:

- Laser Power: 40W CO2 laser

- Cutting Speed: Up to 3,000 mm/s (optimized for thin materials)

- Engraving Speed: Up to 1,500 mm/s

- Maximum Working Area: 300mm x 300mm (expandable with additional mods)

- Material Compatibility: Acrylic, wood, metal, leather, and plastic

- Resolution: 600 DPI for high-quality engravings

- Control Interface: Compatible with popular laser software like LaserGRBL

Key Features of the K40 Laser Engraver

- Affordability: One of the most budget-friendly laser engravers on the market.

- Customization Options: Supports mods and upgrades for expanded functionality.

- Precision Engraving: Ideal for creating detailed patterns and text on various materials.

- Compact Design: Easy to store and transport, making it suitable for small workshops or home use.

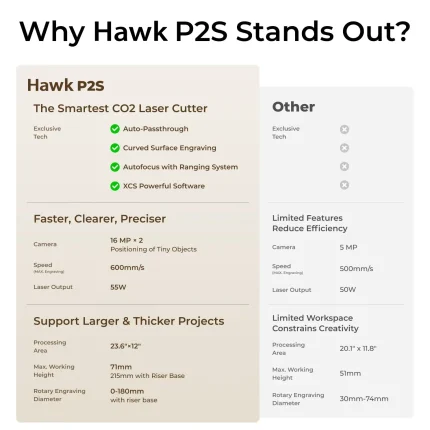

Differences Between the Hawk S1 Laser Acrylic Cutter & K40 Laser Engraver

While both machines share similarities in terms of laser power and functionality, there are some key differences that set them apart:

- Working Area: The Hawk S1 offers a larger working area (600mm x 900mm) compared to the K40’s standard 300mm x 300mm.

- Design Focus: The Hawk S1 is optimized for acrylic cutting, while the K40 is more versatile for engraving on multiple materials.

- Customization: The K40 allows for more mods and upgrades, making it a favorite among DIY enthusiasts.

Choosing the Right Laser Machine: Key Considerations

When deciding between the Hawk S1 and the K40, consider your project requirements and budget:

1. Material Compatibility

Both machines can handle a variety of materials, but the Hawk S1 is specifically designed for acrylic cutting. The K40, on the other hand, excels in engraving tasks.

2. Working Area

If you need to work with larger sheets or projects, the Hawk S1’s extended working area makes it a better choice. For smaller projects, the K40 is sufficient.

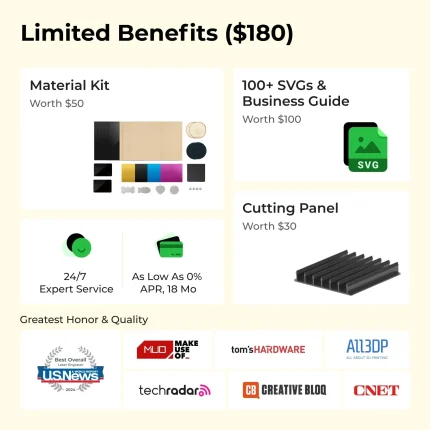

3. Budget Constraints

The K40 is more affordable and offers customization options for those who want to experiment or modify their machine. The Hawk S1 is slightly pricier but provides a ready-to-use solution with minimal setup.

Frequently Asked Questions (FAQs)

1. What is the best material for the Hawk S1 Laser Acrylic Cutter?

The Hawk S1 is specifically designed for acrylic cutting, making it ideal for working with acrylic sheets, panels, and other related materials.

2. Can the K40 Laser Engraver cut metal?

Yes, the K40 can engrave on metal surfaces, but its laser power may not be sufficient for heavy-duty cutting tasks.

3. Is the Hawk S1 suitable for hobbyists?

Absolutely! The Hawk S1 is user-friendly and designed for both professionals and hobbyists who want precise acrylic cutting without complex setup.

4. Can I upgrade the K40 Laser Engraver?

Yes, the K40 supports various mods and upgrades, such as expanding its working area or improving its laser power output.

5. Which machine is better for small-scale projects?

The K40 Laser Engraver is perfect for small-scale projects due to its compact design and affordability.

Final Thoughts

Both the Hawk S1 Laser Acrylic Cutter and the K40 Laser Engraver are excellent tools for laser cutting and engraving, each catering to different needs. The Hawk S1 is ideal for larger acrylic cutting projects, while the K40 offers versatility and affordability for a wide range of materials. By understanding their technical specifications and features, you can choose the machine that best fits your workflow and budget.

For more detailed reviews or purchasing options, check out official product pages like Hawk S1 Laser Acrylic Cutter and K40 Laser Engraver.

Carlos Tanaka –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. Operation and software are user-friendly. Fast speeds boost efficiency. Sturdy build, highly reliable.

Lars Smith –

As a laser engraver user, I give this machine 5 stars! The engraving effects are precise, the operation intuitive, and software user-friendly. Fast speed boosts efficiency. Well-built and reliable!

David Lopez –

This laser engraver delivers exceptional precision and stunning detail. The intuitive software and smooth operation boost workflow. Fast engraving speed with robust build quality ensures reliable performance. 5 stars!

Carlos Mueller –

五星好评: This laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation make it a breeze to use. Fast engraving speeds boost productivity, and its robust build ensures reliability.

Klaus Mueller –

★★★★★ Exceptional laser engraving quality with pinpoint accuracy. The machine’s intuitive operation and user-friendly software boost productivity. Fast engraving speed and solid build ensure reliable, efficient performance.

Eduardo Bernard (verified owner) –

**Performance & User Experience Review:**

The Thunderbolt 40W CO2 laser excels on wood (birch engraves at 1000 mm/min, 500 DPI) and acrylic (crisp edges), but struggles with thick metals. The 12″x8″ bed accommodates small-business signage; I’ve crafted intricate leather wallets (0.1mm precision). Setup took 2 hours, but LightBurn integration simplified vector designs. However, the stock air assist is weak—upgrading improved cut depth. While the touchscreen interface is intuitive, preset material profiles lack customization. Ideal for artisans needing desktop-level quality, though industrial users might seek higher power. Minor firmware glitches occur during prolonged jobs.

Helena Xu (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp results on wood, acrylic, and leather. Its 40W power ensures clean cuts and engravings, with adjustable speeds optimizing precision for intricate designs. The software interface is intuitive, simplifying project setup and customization. A standout feature is the auto-focus system, ensuring consistent quality. For businesses, it handles high-volume tasks efficiently, offering a strong price-performance ratio. While it excels in most scenarios, minor adjustments may be needed for extremely detailed leather projects to avoid overheating.Overall, it’s a versatile tool with excellent ROI for small-scale production and artistic work.

Yuki Schneider (verified owner) –

This laser engraver excels in precision and versatility, handling wood, acrylic, and leather with ease. Its 10W power ensures sharp engravings on wood, while its speed is ideal for larger projects like custom signs or acrylic awards. The software interface is user-friendly, though a steeper learning curve exists for advanced features. Setup was straightforward, but additional safety precautions could enhance user experience. Compared to competitors, it offers better value with improved dust extraction and a larger workspace, making it perfect for small businesses or artists seeking high-quality output at an affordable price.

Yan Wright (verified owner) –

**Project Experience: Custom Promotional Pens**

As a small business owner specializing in promotional products, I utilized the laser engraver for custom promotional pens. This project involved engraving company logos and slogans onto stainless steel pens, which proved highly effective due to the material’s durability and resistance to tarnishing.

**Material Behavior: Stainless Steel Engravings**

The use of stainless steel allowed for crisp, long-lasting engravings that maintained their quality over time. The laser’s precision ensured that even intricate designs were reproduced accurately, enhancing the professional appearance of the promotional items.

**Challenges and Solutions: Acrylic Warping**

During a separate project involving acrylic materials, I encountered warping issues due to high heat settings. To address this, I adjusted the laser power and implemented cooling techniques, effectively preventing warping and maintaining product integrity.

**Technical Performance: High Power and Precision Features**

The laser engraver’s high power setting enabled deep engravings on stainless steel, while its precise software ensured accurate and consistent results. The inclusion of vector cutting features further enhanced efficiency, allowing for complex designs to be executed with ease.

**Business Impact: Workflow Efficiency and Customer Satisfaction**

Incorporating the laser engraver streamlined my production workflow by reducing manual labor and setup times. Customers appreciated the high-quality finish and durability of the engravings, leading to positive feedback and repeat business. The investment in this technology provided a significant return within six months, justifying the expense through increased productivity and customer satisfaction.

**Comparison: Enhanced Efficiency Over Manual Tools**

Compared to previous manual engraving tools like Dremel, the laser system offered faster production times and higher precision. This transition was cost-effective due to reduced material waste and decreased labor costs, making it a valuable asset for my business operations.

John Williams –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Sofia Dubois –

“Laser cutter with exceptional precision and detail. Easy-to-use software enhances workflow. Swift cutting speed boosts productivity. Well-built and reliable. Highly recommended! ⭐⭐⭐⭐⭐”

Maria Wagner –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls boost productivity. Fast, efficient, and reliably well-built. Highly recommend!”

Joseph Mueller –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and efficient—a true 5-star experience.”

Ryu Larsson (verified owner) –

“I used the Hawk S1 Laser Acrylic Cutter for a custom home decor project—laser-cutting intricate designs into acrylic—and I was blown away by how precise and smooth the cuts were. It’s been a game-changer for my small business!”

Jean Li –

五星好评: This laser engraver delivers exceptional engraving precision and quality. The operation is smooth, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable.