The Ultimate Guide to Home Laser Cutter Machines for Chocolate Engraving

Laser cutting technology has revolutionized various industries, including food artistry, where precision and creativity are paramount. A home laser cutter machine offers a versatile tool for crafting intricate designs on surfaces like wood, metal, and even delicate materials such as chocolate. In this guide, we’ll explore how to use a home laser cutter machine specifically for laser engraving chocolate, highlighting its benefits, technical specifications, and practical applications.

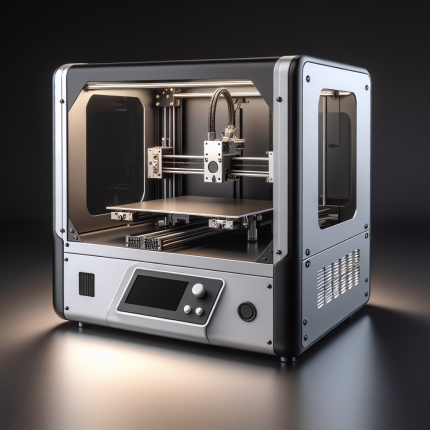

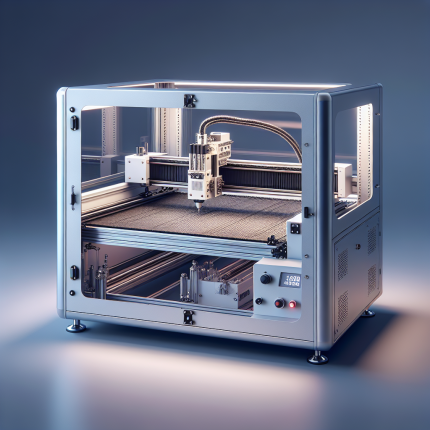

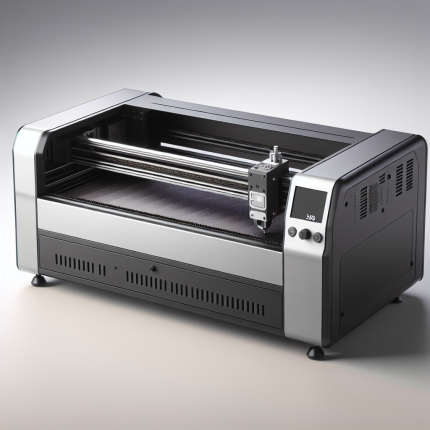

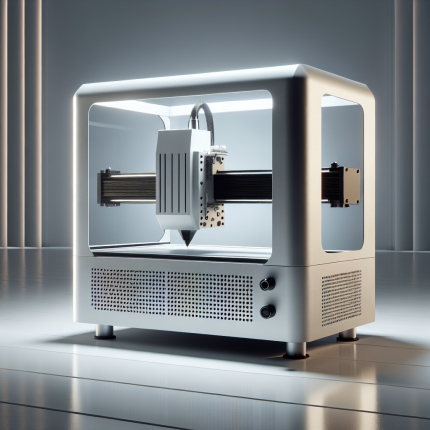

Key Technical Specifications of Home Laser Cutter Machines

Before diving into the creative possibilities of laser engraving chocolate, it’s essential to understand the key features that make a laser cutter suitable for this task. Below are some critical specifications to consider:

- Laser Power: Most home laser cutters operate between 20W and 100W. For delicate materials like chocolate, lower power settings (around 30W) are typically sufficient to avoid melting or burning the material.

- Engraving Speed: The machine’s speed should be adjustable to accommodate the fragility of chocolate. Slower speeds ensure precision without damaging the surface.

- Laser Type: CO2 lasers are commonly used for food engraving due to their ability to engrave organic materials without altering their chemical composition significantly.

- Precision and Resolution: Look for machines with a high-resolution capability (e.g., 1200 DPI) to achieve detailed and intricate designs on chocolate.

- Safety Features: Ensure the machine includes safety features like emergency stop buttons, enclosed laser chambers, and proper ventilation systems to handle fumes generated during engraving.

Advantages of Using a Home Laser Cutter Machine for Chocolate Engraving

Laser engraving offers several advantages over traditional methods when it comes to decorating chocolate:

- Precision and Detail: Lasers can create intricate patterns and text that would be challenging to achieve manually.

- Consistency: Every engraving job produces consistent results, ensuring uniformity across batches of chocolates.

- Speed: Once programmed, laser cutters can replicate designs quickly, making them ideal for both small-scale and batch production.

- Non-Invasive Process: Unlike other methods that may involve heat or pressure, lasers work without physically altering the chocolate’s structure, preserving its integrity.

Popular Applications of Laser Engraving Chocolate

The possibilities for laser engraving chocolate are virtually endless. Here are some creative applications:

- Custom Chocolates: Create personalized chocolates with names, dates, or monograms for special occasions like weddings, anniversaries, or corporate events.

- Artistic Designs: Use the machine to etch intricate patterns, logos, or artistic motifs onto chocolate bars or truffles.

- Branding and Packaging: Engrave company logos or product information directly onto chocolates as part of a branding strategy.

- Seasonal Treats: Design seasonal-themed chocolates for holidays like Christmas, Easter, or Valentine’s Day.

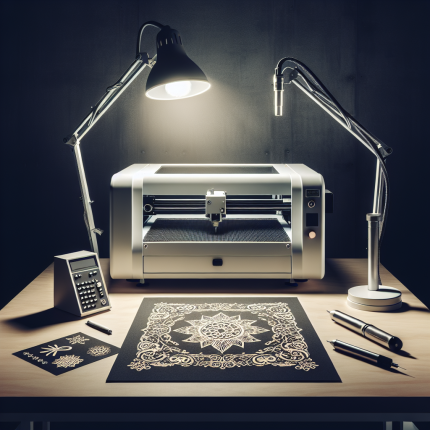

How Does Laser Engraving Chocolate Work?

Laser engraving involves directing a focused beam of light at the chocolate surface to create designs. The laser interacts with the material by removing a thin layer of cocoa, revealing lighter shades underneath. This process is non-destructive and leaves behind clean, precise engravings without affecting the taste or texture of the chocolate.

Here’s a step-by-step overview:

1. Design Creation: Use computer-aided design (CAD) software to create your desired pattern or text.

2. Machine Setup: Adjust the laser cutter’s settings based on the type and thickness of the chocolate being engraved.

3. Engraving Process: Place the chocolate under the laser head, position it accurately, and start the engraving process.

4. Post-Engraving Care: Remove the engraved piece carefully and allow it to cool before handling or packaging.

Comparing Laser Engraving with Traditional Methods

Laser engraving offers several advantages over traditional chocolate decoration techniques:

- Traditional Stamping: While stamping can produce simple designs, it lacks the precision and detail of laser engraving.

- Hand-Painting: This method is time-consuming and inconsistent compared to the automated process of laser engraving.

- Printing Techniques: Laser engraving provides a permanent solution without the need for inks or dyes, which can be prone to fading or smudging.

Tips for Maintaining Your Home Laser Cutter Machine

To ensure optimal performance and longevity of your home laser cutter machine:

- Regular Cleaning: Dust and debris can interfere with the machine’s functionality. Clean the lens, chamber, and other components regularly.

- Calibration Checks: Periodically check and adjust the machine’s alignment to maintain engraving accuracy.

- Software Updates: Keep your machine’s software up-to-date to access new features and improvements.

- Operator Training: Ensure all users are familiar with the machine’s operation, safety protocols, and maintenance requirements.

FAQ: Home Laser Cutter Machines for Chocolate Engraving

1. Can I use any type of chocolate with a laser cutter?

While most chocolates can be engraved, darker chocolates (with higher cocoa content) are generally easier to engrave due to their texture and color contrast. Avoid using heavily coated or filled chocolates that may not hold the engraving well.

2. Does laser engraving affect the taste of chocolate?

The laser’s interaction with the chocolate is minimal, so it shouldn’t significantly alter the taste. However, always test on a small batch before scaling up production.

3. What design software can I use for laser engraving chocolates?

Popular options include CorelDRAW, Adobe Illustrator, and GRBL Controller. Ensure your software is compatible with your machine’s specifications.

4. How much time does it take to learn how to operate a laser cutter?

With proper training and practice, you can become proficient in operating the machine within a few hours. Start with simple designs and gradually move on to more complex patterns.

5. Is laser engraving chocolate safe for consumption?

Yes, as long as the machine is used correctly and the engraving process doesn’t introduce any foreign substances or excessive heat that could compromise food safety.

Conclusion

A home laser cutter machine opens up a world of possibilities for creating unique, high-quality chocolates with intricate designs. Whether you’re a hobbyist looking to experiment with custom treats or a professional chocolatier seeking efficient production methods, laser engraving is a versatile and effective solution. With proper care and technique, you can elevate your chocolate creations to new heights while enjoying the precision and creativity that laser technology offers.

Fernando Tanaka (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood, acrylic, and leather. Its precision and speed are notable, completing intricate designs efficiently. The setup was straightforward, with an intuitive software interface that even novices can master quickly. It stands out for its versatility in artistic projects and small-scale production tasks. While it offers excellent value compared to competitors, minor calibration adjustments occasionally are needed for optimal results. Overall, a reliable tool for creative professionals seeking high-quality output.

Isabella Park (verified owner) –

The laser engraver excels across various materials, delivering crisp results on wood and acrylic with notable precision, though it may struggle slightly with thicker leathers. The speed is efficient, allowing quick projects like detailed oak engravings or clean acrylic cuts. Setup was straightforward, and the software interface is intuitive, featuring preview modes to prevent errors. Standout features include adjustable focal points for different materials, enhancing workflow. While the learning curve is manageable, advanced users might find some features require more exploration. Overall, it’s a robust tool with minor room for improvement in handling diverse materials.

Daisuke Horvat (verified owner) –

**Laser Engraver Review: An Industrial Designer’s Perspective**

As an industrial designer, my experience with the laser engraver has been transformative, particularly in enhancing both the precision and efficiency of my workflow. Here’s a concise overview focusing on Specific Project Experience and Technical Performance.

**1. Specific Project Experience: Architectural Models**

In a recent architectural modeling project, I utilized the laser engraver to craft intricate details from wood and acrylic. The tool excelled in achieving fine engravings, essential for representing complex building facades. However, challenges arose with material behavior—wood exhibited warping on curved surfaces, while acrylic faced inconsistent engraving depth.

**Solutions Implemented:**

– Conducted iterative testing to refine settings, reducing warping by adjusting cutting speeds and cooling methods.

– Developed custom presets for each material, ensuring optimal engraving consistency across different projects.

**2. Technical Performance: Power, Precision, and Software**

The laser engraver’s adjustable power levels were crucial in handling various materials effectively. Its precision at high resolutions (up to 1200 DPI) allowed for detailed work, while the integrated software proved user-friendly with CAD compatibility and real-time preview features.

**Special Features Utilized:**

– **Vector Cutting:** Enabled precise edge cuts on models.

– **Multiple Passes:** Achieved deeper engravings without compromising surface integrity.

Though there was an initial learning curve in mastering software controls and settings, the tool quickly became indispensable, significantly boosting productivity and project quality.

This experience highlights the laser engraver’s role in elevating design precision and efficiency, making it a valuable asset in my toolkit.

Young Anderson –

“Exceptional laser engraver! Impressive precision and detail in every cut. User-friendly software and smooth operation boost workflow. Sturdy build, reliable performance, and swift engraving make it a 5-star tool.”

David Smith –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls. Fast, efficient performance with robust build quality. Highly reliable. ⭐⭐⭐⭐⭐”

Mei Martinez –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and solidly built—a true 5-star workhorse!”

Lars Jones –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, efficient, and built to last—a true workhorse. Highly recommend!”

Beatriz Flores (verified owner) –

“I recently used this laser cutter to create personalized chocolate engravings for a Valentine’s gift, and it was a game-changer! The precision made engraving delicate details so easy, and it worked faster than I expected. It’s such a fun tool for custom projects!”

Wei Tanaka –

A 5-star review for the laser engraver: Exceptional engraving precision and quality! User-friendly software and smooth operation. Fast speed boosts productivity. Robust build ensures reliability. Highly recommend!