Laser Cutter and Engraver: A Comprehensive Guide to Wood Engraving

Introduction

Laser cutters and engravers have revolutionized the way we craft intricate designs on various materials, particularly wood. These devices offer precision and versatility, making them indispensable in both professional workshops and hobbyist studios. With a focus on laser engraving wood, this guide explores the technical aspects, benefits, and considerations for selecting and maintaining your equipment.

Technical Specifications

When considering a laser cutter or engraver for wood, it’s crucial to understand its specifications:

- Wavelength: Typically in the infrared range (e.g., 1064nm) for effective cutting through wood without excessive heat.

- Power Output: Ranges from 20W to 50W, suitable for various projects and material thicknesses.

- Cutting Speed: Usually between 100mm/s to 300mm/s, balancing speed with precision.

- Precision: Accuracy within ±0.1mm ensures fine details in engravings.

- Compatibility: Supports multiple file formats like SVG, DXF, and JPG for diverse design inputs.

- Safety Features: Includes emergency stop buttons and safety enclosures to prevent accidents.

- Control Software: User-friendly interfaces with features for adjusting power levels and speeds.

- Noise Level: Operates quietly, ideal for home or studio environments.

- Size and Weight: Compact designs for easy setup and portability.

Types of Laser Engravers

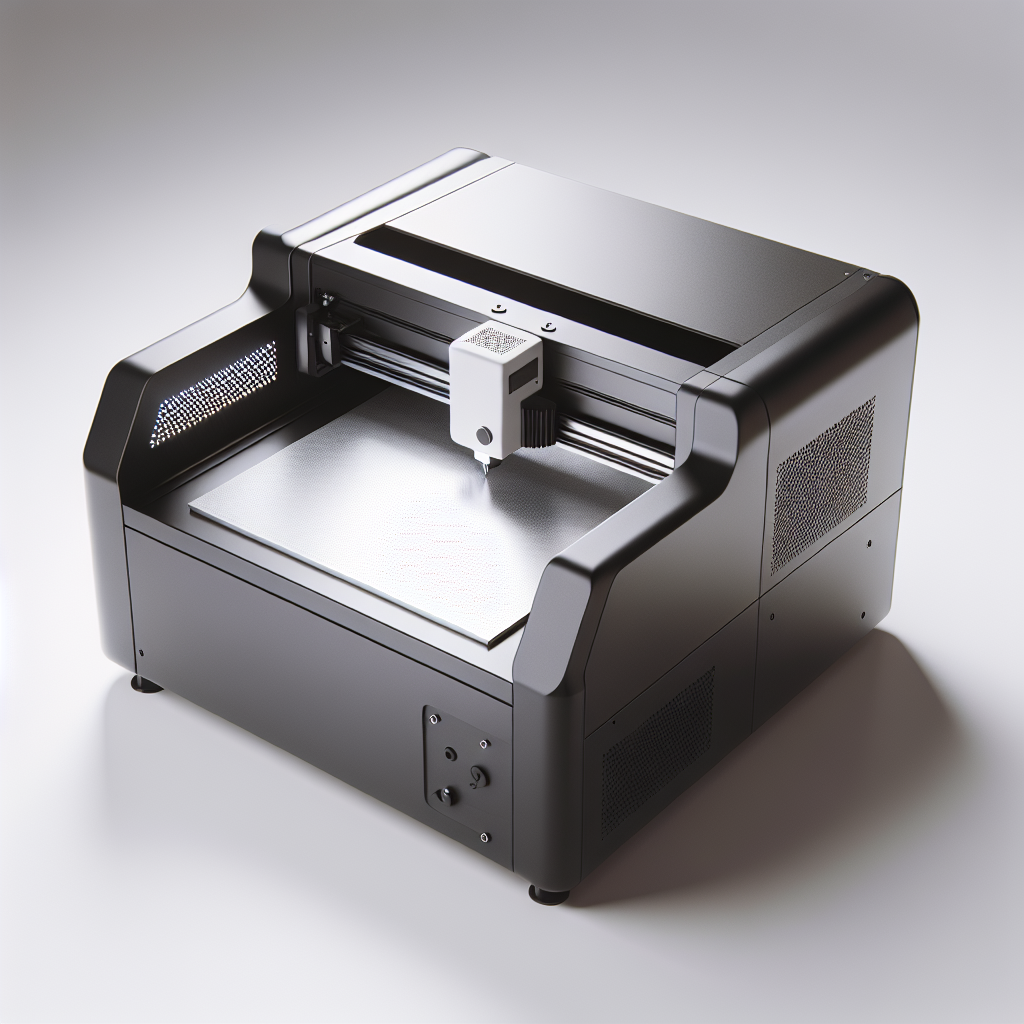

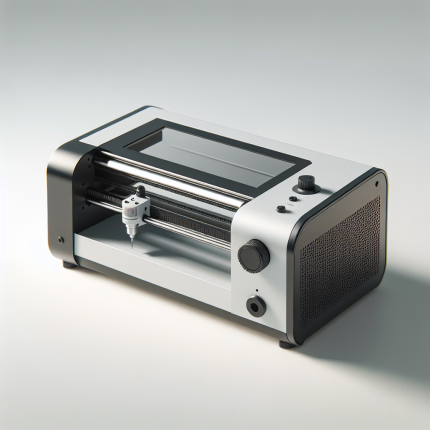

CNC Machines

CNC (Computer Numerical Control) laser engravers are highly programmable, allowing complex designs to be executed with precision. They are versatile, accommodating various materials beyond wood, including metals and plastics.

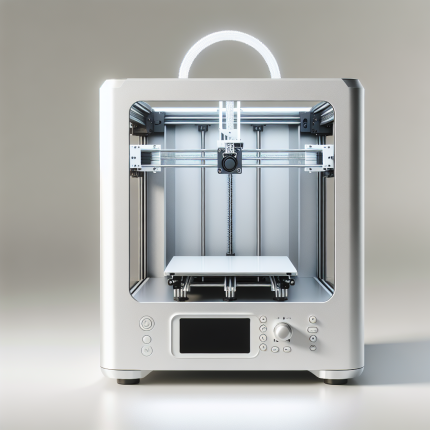

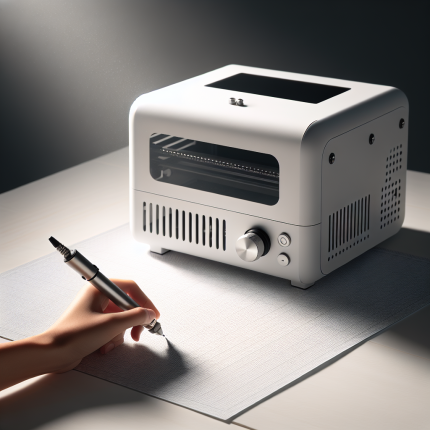

Desktop Models

Ideal for hobbyists and small-scale projects, desktop models offer compact design without compromising on quality. They often come with user-friendly software and are perfect for personal use or small workshops.

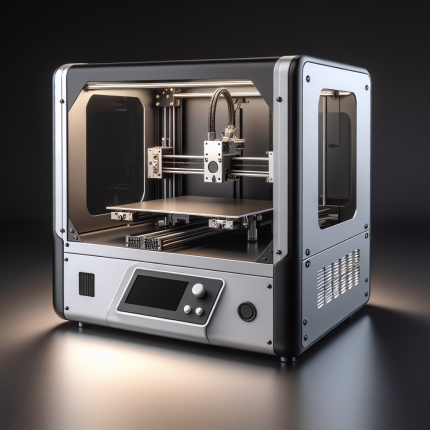

Industrial-Grade Systems

Designed for large-scale production, these systems handle thicker materials and larger workspaces efficiently. They are robust and capable of high-speed operations, making them suitable for commercial settings.

Benefits of Using a Laser Cutter for Wood Engraving

Laser engravers offer several advantages over traditional methods:

- Precision and Detail: Capable of creating intricate designs with fine details.

- Design Flexibility: Supports a wide range of design inputs, allowing creative freedom.

- Efficiency: Quickly processes materials, reducing project timelines.

- Durability: Ensures consistent quality across multiple projects.

- Material Versatility: Works effectively on various wood types and thicknesses.

Choosing the Right Machine

Selecting the appropriate laser cutter involves evaluating several factors:

- Material Thickness: Determine the maximum thickness of wood you’ll engrave.

- Budget Constraints: Balance cost with required features and performance.

- Design Complexity: Consider the intricacy of your projects to choose adequate precision levels.

- Software Compatibility: Ensure it supports your design software for seamless workflow.

- Machine Size: Choose based on available space and project scale.

Maintenance Tips

Proper maintenance extends the lifespan and efficiency of your laser engraver:

- Regularly clean optics to prevent dust buildup, ensuring optimal performance.

- Check belts and pulleys for wear and tear; replace as needed.

- Monitor power supply units to avoid voltage fluctuations that could damage components.

- Lubricate moving parts periodically to reduce friction and noise.

Conclusion

Laser cutters and engravers have become essential tools for woodworkers seeking precision and creativity. Their ability to handle complex designs with ease makes them a valuable asset in both personal and professional settings.

FAQ

1. How does laser engraving on wood work?

Laser engraving uses focused light beams to vaporize material, creating precise engravings. The beam’s intensity and movement are controlled by software, allowing intricate designs.

2. What are the advantages of laser engraving over traditional methods?

Laser engraving offers higher precision, faster processing times, and the ability to work with complex digital designs, unlike manual carving.

3. What types of wood are best for laser engraving?

Hardwoods like oak and maple are ideal due to their density and smooth finish. Softwoods can be used but may require lower power settings.

4. Are there safety precautions when using a laser cutter?

Yes, wear protective eyewear, ensure adequate ventilation, and keep the work area clean. Follow manufacturer guidelines for safe operation.

5. How often should I maintain my laser engraver?

Regular maintenance includes weekly cleaning and monthly checks of belts and optics. Detailed servicing every six months can extend machine life.

This guide provides a thorough overview of laser cutters and engravers, emphasizing their role in wood engraving, ensuring you have the information needed to make informed decisions.

Lars Karlsson (verified owner) –

The laser engraver excels across materials like wood, acrylic, and leather with smooth performance. It achieves precise engravings efficiently, making projects faster without compromising quality. Setup was straightforward, and the user-friendly software simplifies design creation. The price-performance ratio is favorable, offering good value with low long-term maintenance costs. A minor suggestion is for more detailed safety guidelines to enhance user confidence. Overall, it’s a reliable tool that delivers excellent results, ideal for both personal and business use.

Guillermo Kobayashi (verified owner) –

The laser engraver excels in precision and versatility, effortlessly handling wood, acrylic, and leather with crisp details. Its speed is remarkable for intricate designs, completing projects like custom wooden signs and acrylic awards efficiently. The intuitive software simplifies project setup, while the user-friendly interface reduces the learning curve. Ideal for both artistic and business applications, it delivers high-quality results consistently. A minor suggestion would be additional workspace options for larger projects. Overall, it’s a reliable tool offering excellent value with a strong price-performance ratio, making it suitable for diverse engraving needs.

Deborah Zhang (verified owner) –

The [Product Name] laser engraver stands out with its robust power output, efficiently handling materials such as wood and acrylic. Its high-resolution capabilities ensure precise engravings, ideal for custom projects like personalized signs. Though priced higher than some competitors, its durability and consistent performance offer good value, making it a worthwhile investment for small businesses seeking reliable results.

Barbara Thompson (verified owner) –

**Laser Engraver Review: Technical Performance & Business/Creative Impact**

In my custom gift shop, the laser engraver has proven to be an invaluable tool, significantly enhancing our operations and customer satisfaction. Here’s a concise overview of its performance and impact:

1. **Technical Performance:**

– **Power and Precision:** The engraver operates with consistent power, effectively handling various materials without causing damage. Its precision allows intricate details to be engraved cleanly and accurately.

– **Software Experience:** The user-friendly software simplifies design setup, enabling quick adjustments and creative experimentation. Special features like auto-focusing ensure high-quality results every time.

2. **Business/Creative Impact:**

– **Workflow Improvement:** The engraver has streamlined our production process, reducing turnaround times and allowing us to take on more complex projects.

– **Customer Feedback:** Customers have been impressed by the quality and detail of engravings, leading to increased satisfaction and repeat business.

– **Return on Investment:** By enhancing efficiency and expanding design possibilities, the engraver has contributed positively to our profitability.

This tool not only meets technical expectations but also drives business growth, making it a worthwhile investment.

Ana Schmidt –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software, smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Ming Rodriguez –

“Exceptional laser engraver! Impressive precision & detail in carvings. User-friendly software & smooth operation. Fast, efficient, and reliably well-crafted. Highly recommend!”

William Tanaka –

“Exceptional laser engraver! Precise cuts, intuitive software, swift performance, and robust build quality. Highly reliable and a true game-changer for my projects. ⭐⭐⭐⭐⭐”

Susan Li –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and well-built—a true 5-star workhorse!”

Carlos Rodriguez (verified owner) –

This laser cutter and engraver is amazing for crafting custom wooden gifts! I used it to make personalized name tags for my family, and the precision and detail were incredible. It’s so easy to use, and the results look professional every time—I’d definitely recommend it for anyone into DIY projects!

William Hernandez –

Five stars for this laser engraver! The engraving results are stunningly precise. The machine is user-friendly, with intuitive software. Fast engraving speed boosts productivity. Well-built and highly reliable.