The Best Laser Cutter for Acrylic and Small Laser Engraver: A Comprehensive Guide

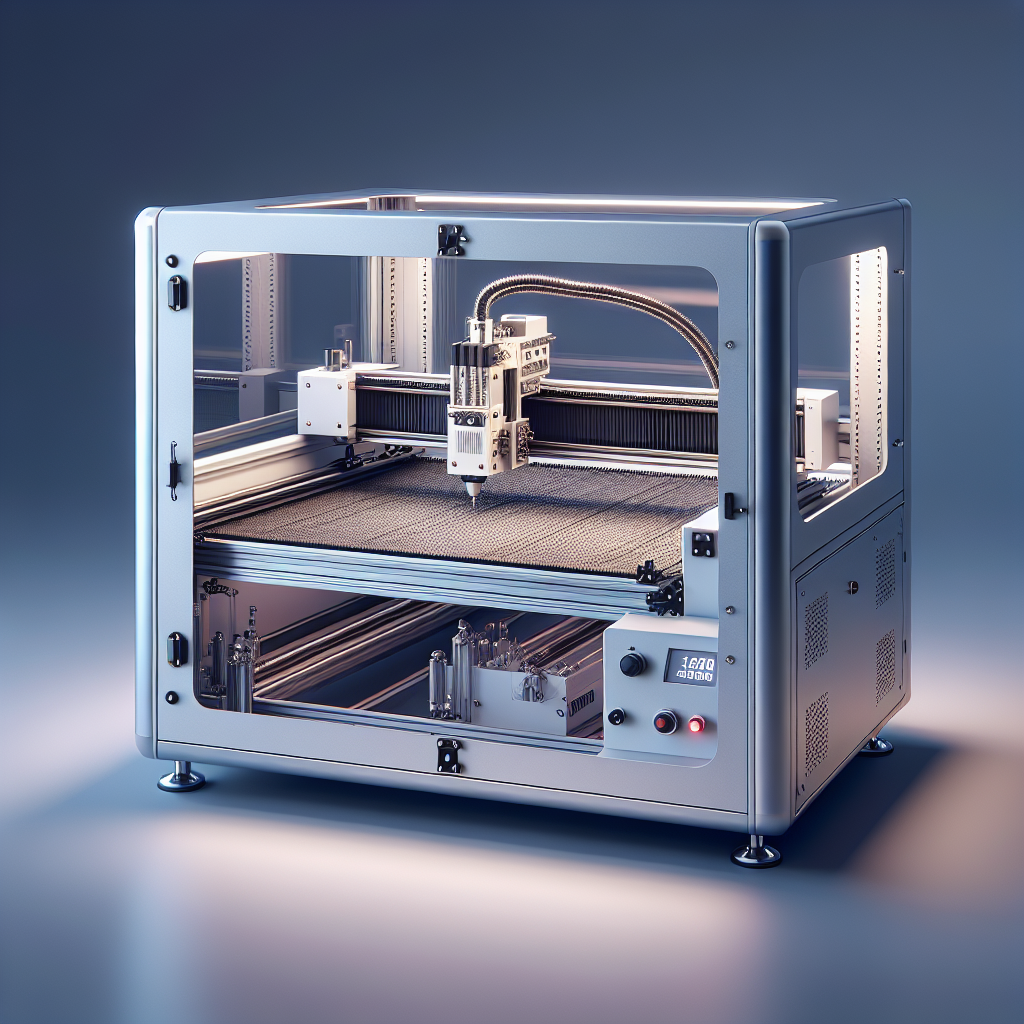

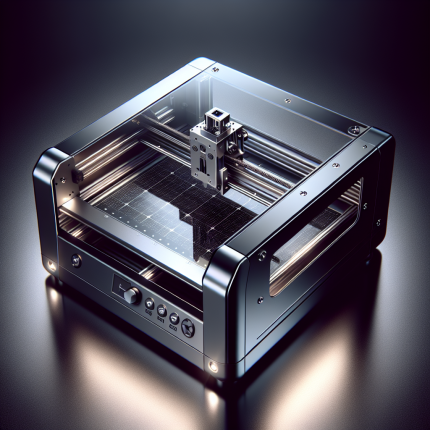

Laser cutting technology has revolutionized industries ranging from prototyping to artistry, offering precision and efficiency that traditional tools simply cannot match. For those working with acrylic materials or seeking a compact solution for small-scale laser engraving, the laser cutter for acrylic and small laser engraver are indispensable tools. This guide will explore the features, benefits, and technical specifications of these devices, helping you understand their capabilities and applications.

Introduction to Laser Cutters for Acrylic

A laser cutter for acrylic is designed specifically to handle the unique properties of acrylic materials. Acrylic, also known as PMMA (polymethyl methacrylate), is a popular choice in industries due to its transparency, durability, and ease of. However, cutting acrylic requires precision to avoid melting or warping the material.

Key Features of Laser Cutters for Acrylic

- Precision Cutting: The ability to achieve intricate designs with minimal material waste.

- Versatility: Suitable for both large-scale projects and small, detailed work.

- Speed: Fast processing times compared to traditional cutting methods.

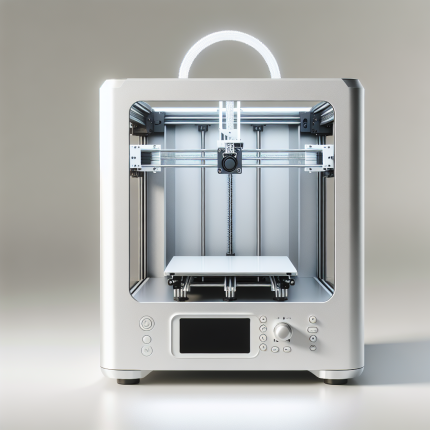

Technical Specifications of a Small Laser Engraver

When choosing a small laser engraver, it’s essential to consider its technical specifications to ensure it meets your project requirements. Below are some critical features to look for:

Power Output (Watts)

The power output determines the machine’s ability to cut through different materials, including acrylic. Higher wattage allows for faster cutting and deeper engraving.

Build Quality

A sturdy build ensures longevity and accuracy. Look for machines with durable components, such as high-quality optics and robust frames.

Software Compatibility

Most laser engravers come with user-friendly software that supports popular file formats like SVG, DXF, and PDF. Ensure the machine is compatible with your existing design tools.

Cooling System

A reliable cooling system prevents overheating during extended use, ensuring consistent performance.

Safety Features

Laser cutting involves high energy, so safety features like emergency stop buttons and protective covers are essential.

Advantages of Using a Laser Cutter for Acrylic

1. Precision and Accuracy

Laser cutters offer unmatched precision, making them ideal for creating intricate designs on acrylic sheets.

2. Reduced Material Waste

Unlike traditional cutting methods, laser cutting minimizes material waste by following precise paths dictated by digital designs.

3. Versatility in Design

Acrylic can be engraved or cut to create a variety of products, from signage and display cases to decorative items and prototypes.

4. Time Efficiency

Laser cutters process materials quickly, reducing production time and increasing overall efficiency.

Use Cases for Laser Cutters and Small Laser Engravers

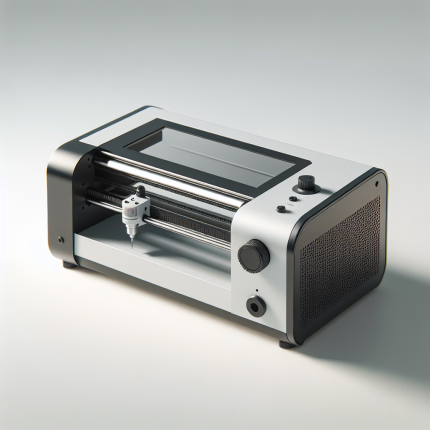

Prototyping

Small businesses and hobbyists often use laser cutters for rapid prototyping, allowing them to test designs before full-scale production.

Artistic Applications

Artisans and designers rely on laser engravers to create detailed acrylic art pieces, such as decorative panels or custom signage.

Industrial Applications

In industries like electronics and automotive manufacturing, laser cutters are used to produce precision components from acrylic materials.

Choosing the Right Laser Cutter for Your Needs

When selecting a laser cutter for acrylic, consider factors such as your project size, budget, and desired level of customization. For small-scale projects, a compact small laser engraver may suffice, while larger operations may require industrial-grade machines.

Frequently Asked Questions (FAQs)

1. Can I use a laser cutter for other materials besides acrylic?

Yes, most laser cutters are capable of cutting and engraving various materials, including wood, metal, glass, and plastic. However, the optimal settings may vary depending on the material type.

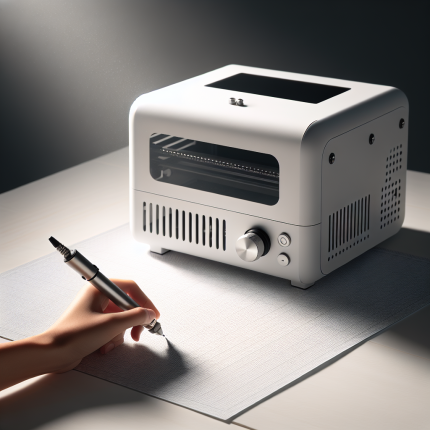

2. What is the difference between a laser cutter and a small laser engraver?

A laser cutter is typically used for cutting through materials entirely, while a small laser engraver focuses on creating detailed designs or patterns on the surface of the material without cutting through it.

3. Do I need special safety equipment when using a laser cutter?

Yes, protective eyewear and gloves are essential to prevent injuries from laser exposure and hot surfaces. Additionally, ensure proper ventilation in your workspace to avoid inhaling fumes produced during cutting.

4. How much does a laser cutter for acrylic cost?

The cost of a laser cutter for acrylic varies depending on its size, power output, and additional features. Entry-level models may start around $500, while industrial-grade machines can exceed $10,000.

5. How easy is it to set up and use a small laser engraver?

Most modern small laser engravers come with intuitive software and straightforward setup processes. With minimal training, users can begin creating designs within minutes.

Conclusion

A laser cutter for acrylic or small laser engraver is an invaluable tool for anyone working with acrylic materials, offering precision, versatility, and efficiency. By understanding the technical specifications and applications of these devices, you can choose the right machine to meet your project needs. Whether you’re a hobbyist, artist, or industrial professional, investing in quality laser cutting equipment will undoubtedly enhance your workflow and creative possibilities.

For more information on laser cutting technology, consider exploring resources from reputable manufacturers or joining online communities dedicated to laser engraving and cutting. These platforms often provide valuable insights, tutorials, and troubleshooting tips for users of all skill levels.

Sophie Schaefer (verified owner) –

The laser engraver excels in versatility, delivering precise engravings on wood, acrylic, and leather with consistent speed. The software interface is intuitive, streamlining setup and operation, though a steeper learning curve could benefit from enhanced tutorials. Its compact workspace suits small-scale projects, making it ideal for artisans. While the price-performance ratio is strong, investing in additional dust management accessories would enhance long-term usability.Overall, this engraver stands out for its reliability and ease of use, offering excellent value for hobbyists and small businesses alike.

Robert Saito (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering precise and vibrant results. Its speed is notable on large projects, such as detailed signage or intricate artwork. The user-friendly software interface simplifies setup, with auto-focusing enhancing accuracy. Compared to competitors, it offers superior precision at a competitive price, though adding dust collection would improve safety. Ideal for small businesses and artists seeking reliable engraving solutions.

Katarina Schaefer (verified owner) –

The laser engraver excels in precision and speed, delivering crisp engravings on wood, acrylic, and leather with minimal setup. Its adjustable power settings accommodate diverse materials, ensuring optimal results. The software interface is user-friendly, though novices may require initial guidance. Standout features include real-time preview and automated focus, enhancing efficiency for projects like custom wooden signs and acrylic awards. While the price aligns well with its capabilities, additional tutorials could aid new users. Overall, it’s a versatile tool for both personal and professional use, offering excellent value and reliability in various applications.

Marco Bernard –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably built. Highly recommend!”

Carlos Garcia –

“Exceptional laser engraver! Impressive precision and detail in every cut. User-friendly software and smooth operation boost efficiency. Sturdy build, reliable performance, and rapid engraving speeds make it a true 5-star gem!”

Wei Chen –

“Exceptional laser engraver! Precise cuts, intuitive software, swift operation, and robust build quality. Highly reliable, it boosts my workshop’s efficiency.”

Richard Wagner –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls boost productivity. Fast, reliable, and well-built—a true workhorse. Highly recommend!”

Ming Horvat (verified owner) –

This laser cutter is a game-changer for my small projects! It’s super fast and precise, especially when I’m working on delicate acrylic jewelry pieces. No more hassle—just clean cuts every time!

Jin Lopez –

Five stars for this laser engraver! The engraving quality and precision are top-notch. The machine is user-friendly, software intuitive. Fast engraving speeds boost my productivity. Solid build, highly reliable.