Laser Cutting and Engraving Machine: A Comprehensive Guide

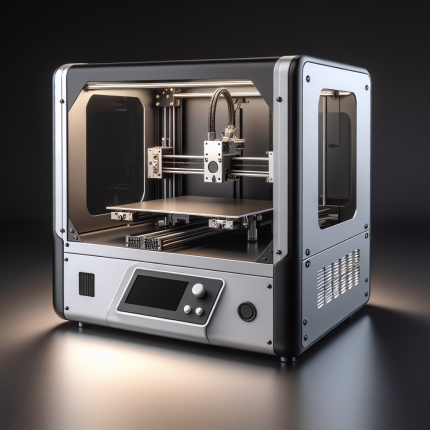

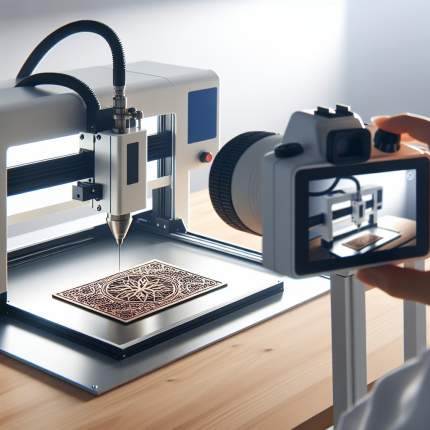

Introduction to Laser Cutting Machines

Laser cutting machines have revolutionized the world of craftsmanship, offering precise and efficient solutions for various projects. These machines are particularly popular in wood engraving, where intricate designs can be etched with remarkable accuracy. This guide will explore the best woods for laser engraving, technical specifications, maintenance tips, and more.

Choosing the Best Wood for Laser Engraving

Selecting the right wood is crucial for achieving high-quality engravings. Factors such as density, moisture content, and grain patterns play significant roles in the outcome of your project. Here’s a guide to help you choose the best wood types:

- Basswood: Ideal for detailed work due to its soft texture and fine grain.

- Plywood: Offers consistent results with varying layers of wood.

- Oak: Known for durability, it’s perfect for engravings that need longevity.

Each wood type interacts differently with laser settings, so understanding these dynamics is key to successful engraving.

Types of Wood for Engraving

Basswood

- Density: Low density makes it easy to engrave intricate details.

- Grain Pattern: Fine and uniform, ensuring smooth engravings.

Plywood

- Layers: Consistent layers provide uniform results across the board.

- Durability: Holds up well under various laser settings.

Oak

- Texture: Medium texture with a coarse grain pattern.

- Moisture Content: Low moisture content reduces the risk of burns.

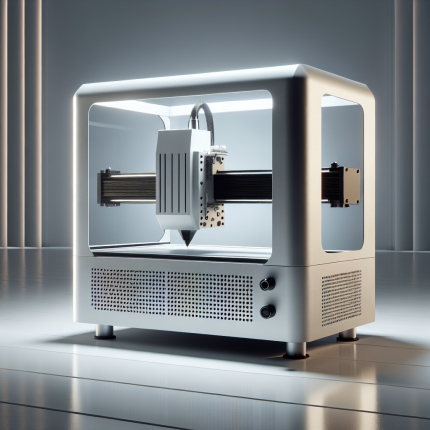

Technical Specifications for Laser Cutting Machines

To achieve optimal results, consider these specifications:

- Power Levels: Adjust between 20W to 100W depending on wood density.

- Speed Range: Set speeds from 100mm/s to 500mm/s based on design complexity.

- Precision: Ensure laser heads have a spot size of 0.1 to 0.3 mm for sharp engravings.

- Safety Features: Look for machines with emergency stop buttons and fume extraction systems.

Maintenance Tips for Laser Machines

Regular maintenance ensures consistent performance:

- Cleanliness: Regularly clean the laser head and optics to prevent dust buildup.

- Lubrication: Keep moving parts lubricated to extend machine life.

- Software Updates: Ensure your machine’s software is up-to-date for optimal functionality.

Best Practices for Engraving

Adjusting laser settings based on wood type is essential. For Basswood, lower power levels are sufficient, while Oak may require higher settings. Experimentation and practice will help you master the technique.

Conclusion

Exploring different woods and understanding your machine’s capabilities can elevate your engraving projects. By following these guidelines, you’ll unlock new creative possibilities with your laser cutting machine.

FAQ Section

- What are the best woods for laser engraving?

-

Basswood, plywood, and oak are top choices due to their texture and density.

-

How do I adjust laser settings for different woods?

-

Start with lower power levels for softerwoods and increase for denser materials.

-

What maintenance is required for my laser machine?

-

Regular cleaning, lubrication, and software updates are essential.

-

Can I use any software with my laser machine?

-

Ensure compatibility by checking the manufacturer’s recommendations or consulting tutorials online.

-

How do I avoid common mistakes in engraving?

- Test on scrap wood first to refine settings and practice your technique.

By following this guide, you can enhance your laser engraving projects with professional results.

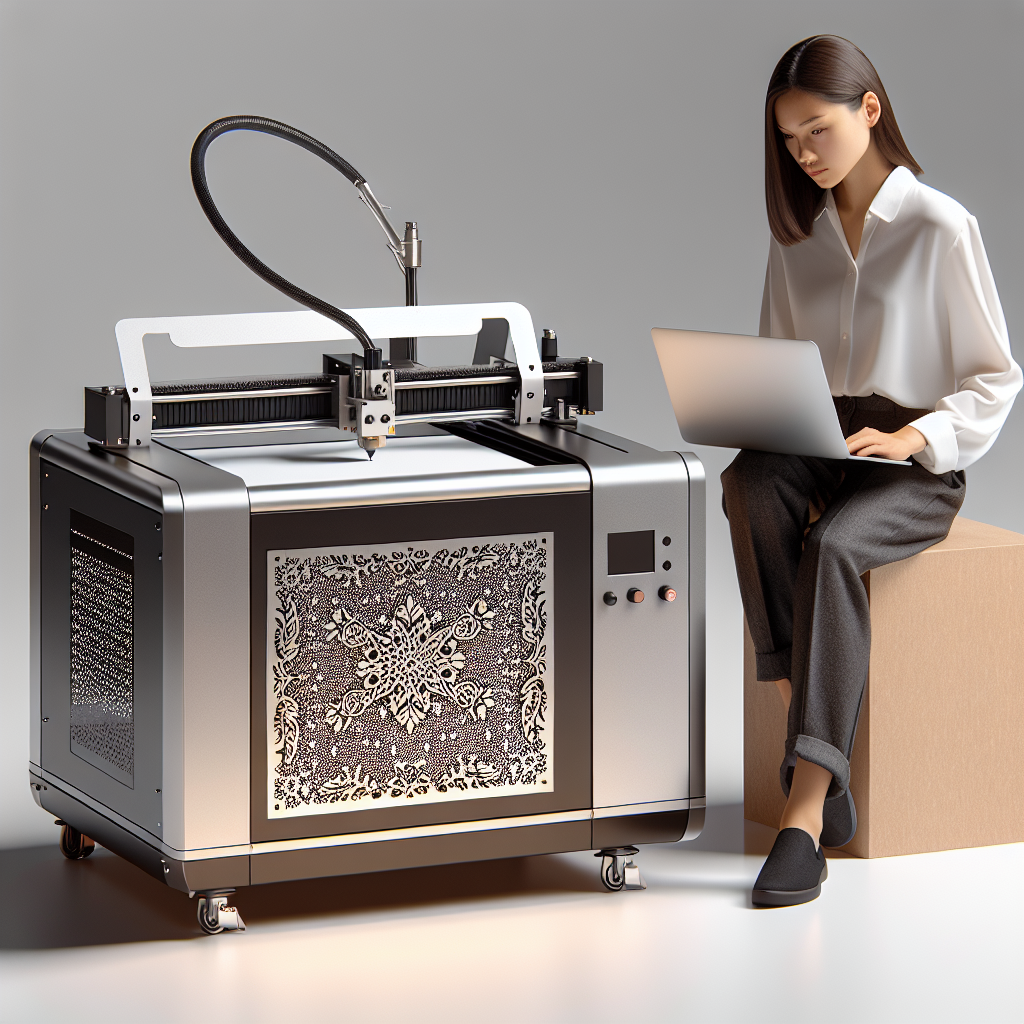

Elena Rivera (verified owner) –

The laser engraver excels in processing wood, acrylic, and leather, delivering sharp engravings on wood and clean cuts on acrylic. Its precision is remarkable at 1200 DPI, as seen in intricate designs on a custom metal nameplate. The software interface is user-friendly, with intuitive tools for scaling and rotating designs. A standout feature is the real-time preview, ensuring accurate project execution. While it handles small-scale projects efficiently, larger works may require multiple passes. Overall, it’s a versatile tool for hobbyists and small businesses, offering excellent value for its performance.

Thomas Novak (verified owner) –

The laser engraver excels in performance across various materials, delivering precise cuts on wood, acrylic, and leather. Its speed of 600mm/s ensures efficient processing without compromising quality. The user-friendly software interface streamlines project setup, while the auto-focusing feature enhances accuracy. For artistic applications, it handles intricate designs seamlessly, making it ideal for personalized jewelry or signage production. The 40W laser with up to 1200 DPI resolution and a 30x30cm workspace offer versatility, though higher power might be needed for tougher materials. Overall, it balances performance and usability, offering great value for hobbyists and small-scale businesses.

Hiroshi Chen (verified owner) –

The laser engraver excels in performance, delivering sharp engravings on wood, acrylic, and leather with impressive precision. Its speed is notable for large projects, though it slows slightly on intricate details. The software interface is user-friendly, with a clean layout that simplifies design uploads and adjustments. A standout feature is the air assist system, which reduces smoke and debris during engraving. Compared to similar models, its compact size and high-quality output make it a strong contender for small-scale businesses or hobbyists. Minor suggestion: adding more preset templates would enhance usability. Overall, it offers excellent value for its performance capabilities.

Klaus Zhang –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

William Wang –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and solidly built—a true 5-star workhorse!”

Jean Wagner –

“Exceptional laser engraver! Impressive precision and detail in every cut. User-friendly software and intuitive controls boost workflow. Fast, efficient, and reliably well-crafted. Highly recommend!”

Juan Schmidt –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift operation, and robust build quality. Highly reliable and efficient—a true 5-star experience.”

Emily Davis (verified owner) –

I recently bought this laser machine and it’s been a game-changer! I made custom engraved wooden coasters for my friends—it was so easy to use the software and the cuts were precise and super fast. The best part? It worked perfectly on plywood, giving such clean lines. Highly recommend for anyone looking to make quick, personalized gifts.

Elizabeth Fischer –

As a laser engraver user, I give this machine 5 stars. The engraving effects and precision are top-notch. Operation is smooth, software intuitive. Fast engraving speed boosts efficiency. Solid build, highly reliable.