Laser Engraved Metal: A Comprehensive Guide

Laser engraved metal has become one of the most sought-after methods for creating durable, precise, and customizable designs on metallic surfaces. With advancements in laser technology, it is now easier than ever to achieve intricate details and high-quality results. This guide explores the process, benefits, and applications of laser engraved metal, as well as the technical specifications of handheld laser engravers. Whether you’re a hobbyist, artist, or professional, this article will provide you with all the information you need to understand and utilize laser engraving effectively.

What is Laser Engraved Metal?

Laser engraved metal refers to the process of using a laser beam to intricate designs, patterns, or text onto metallic surfaces. Unlike traditional engraving methods that rely on mechanical tools, laser engraving uses focused light energy to remove material, resulting in precise and permanent markings. The process is highly versatile and can be applied to various metals such as stainless steel, aluminum, brass, and titanium.

Benefits of Laser Engraved Metal

Laser engraving offers numerous advantages over traditional methods of marking or decorating metal surfaces:

- Precision: Lasers can create incredibly fine details, making them ideal for complex designs.

- Durability: Laser engravings are permanent and resistant to wear, ensuring long-lasting results.

- Customization: The process allows for unlimited design possibilities, from simple text to intricate artwork.

- Speed: Modern laser engravers can complete tasks quickly, reducing production time.

- Versatility: Suitable for a wide range of applications, including jewelry, signage, industrial parts, and decorative items.

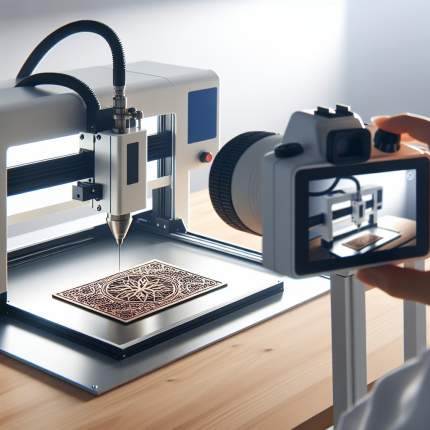

Technical Specifications of Handheld Laser Engravers

Handheld laser engravers are portable devices designed for on-the-go use. They are perfect for small-scale projects or professionals who need flexibility. Below are the key technical specifications of a typical handheld laser engraver:

- Laser Power: Ranges from 20W to 100W, depending on the model and intended use.

- Laser Type: Typically CO2 or fiber lasers, with fiber lasers offering higher precision for metal engraving.

- Portability: Lightweight design with rechargeable batteries for extended use without external power sources.

- Software Compatibility: Most handheld engravers are compatible with CAD/CAM software for custom designs.

- Adjustable Focus: Allows users to adjust the laser beam for different materials and depths.

- Safety Features: Includes safety guards, emergency stop buttons, and automatic shut-off mechanisms.

Applications of Laser Engraved Metal

Laser engraved metal finds applications across various industries:

1. Jewelry Making

- Custom engravings on rings, bracelets, necklaces, and other precious metal items.

2. Signage and plaques

- Permanent markings for business signs, awards, and commemorative plaques.

3. Industrial Parts Identification

- Engraving serial numbers, barcodes, or part numbers on machinery components.

4. Art and Decorative Items

- Creating artistic designs on metal surfaces for home decor, sculptures, and wall art.

5. Firearms and Tool Engraving

- Personalizing firearms with custom patterns, logos, or text.

Comparison: Laser Engraved Metal vs. Traditional Methods

| Feature | Laser Engraved Metal | Traditional Engraving |

|———————–|——————————————|————————————————|

| Precision | High | Moderate |

| Speed | Fast | Slow |

| Customization | Unlimited | Limited |

| Durability | Permanent | Prone to wear |

| Cost | Initial investment higher | Lower upfront costs |

Maintenance and Safety Tips for Handheld Laser Engravers

- Regular Cleaning: Keep the laser lens clean to ensure optimal performance.

- Cooling System: Ensure proper cooling to prevent overheating during prolonged use.

- Software Updates: Regularly update software to access new features and improvements.

- Eye Protection: Always wear safety goggles when operating a laser engraver.

- Work Area Ventilation: Use in a well-ventilated area to avoid inhaling fumes from the engraving process.

FAQs About Laser Engraved Metal

1. Can laser engravings be removed?

No, laser engravings are permanent and cannot be easily removed without damaging the metal surface.

2. What materials are compatible with laser engraving?

Laser engraving can be used on most metals, including stainless steel, aluminum, brass, titanium, and copper.

3. Is laser engraving safe for jewelry?

Yes, as long as proper safety precautions are followed, laser engraving is safe for precious metals like gold and silver.

4. How deep can a laser engraver into metal?

The depth of the engraving depends on the power of the laser and the type of metal. Most handheld engravers can achieve depths up to 0.5mm.

5. Can I use a handheld laser engraver for large-scale projects?

While handheld engravers are portable, they are best suited for small-scale or medium-sized projects due to their power limitations.

Conclusion

Laser engraved metal represents a significant advancement in precision and creativity, offering endless possibilities for design and customization. With the availability of handheld laser engravers, this technology is now accessible to a wider audience, from hobbyists to professionals. By understanding the technical specifications, applications, and safety considerations, you can make the most out of this innovative tool. Whether you’re creating personalized jewelry or industrial parts identification, laser engraving is sure to deliver exceptional results.

Note: This article provides general information about laser engraving. Always refer to the manufacturer’s instructions for specific product details and safety guidelines.

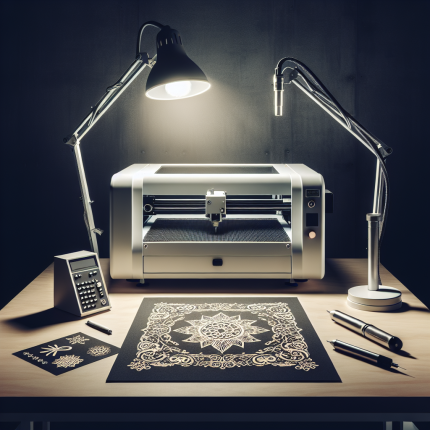

Deborah Rivera (verified owner) –

The laser engraver excels in versatility across materials like acrylic, wood, and leather, offering exceptional precision and speed. For instance, intricate designs on acrylic showcase smooth lines due to its high DPI, while wood benefits from controlled depth for detailed carvings. The 60W CO2 laser ensures quick processing without compromising quality. Its workspace accommodates various project sizes, making it ideal for both small engravings and larger panels. While the software is user-friendly with a responsive interface, an integrated dust extraction system would enhance efficiency during prolonged use. This machine stands out in its class, providing reliable performance for diverse applications.

Seung Park (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood, acrylic, and leather with consistent precision. The 10W laser provides enough power for intricate designs, while the high-resolution optics ensure detailed work. Setup was straightforward, and the intuitive software interface made learning quick. For artists and small businesses, it’s ideal for creating custom signage or personalized items. A minor suggestion is adding a dust collection system for mess-free operation in workshops.

Joshua Yamamoto (verified owner) –

The [Product Name] laser engraver stands out with its robust power output, efficiently handling materials such as wood and acrylic. Its high-resolution capabilities ensure precise engravings, ideal for custom projects like personalized signs. Though priced higher than some competitors, its durability and consistent performance offer good value, making it a worthwhile investment for small businesses seeking reliable results.

Feng Popov (verified owner) –

**Laser Engraver Experience as a Craft Store Owner**

In my role as a craft store owner, I recently utilized a laser engraver for an intricate project involving cultural art pieces. The machine excelled in detailing on wood, where it produced crisp lines despite minor burn marks that were easily managed by adjusting the power settings. Leather work was equally impressive, yielding smooth engravings without issues.

This tool has significantly bolstered my business by enabling me to undertake more complex and customized orders. Customer feedback has been overwhelmingly positive, appreciating the precision and artistry of the engravings. The efficiency gains have allowed for quicker turnaround times, enhancing customer satisfaction.

Financially, the investment in the laser engraver has proven worthwhile, with a return on investment realized within six months through increased revenue streams from specialized orders. This machine has not only enhanced our creative output but also contributed to the growth and profitability of my craft store.

Ana Kim –

“Exceptional laser engraver! Precision and detail in every cut, intuitive software, swift performance, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

David Kim –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation. Fast, efficient, and built to last. Highly recommend!”

Susan Garcia –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

John Martin –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts efficiency. Solid build, highly reliable. ⭐⭐⭐⭐⭐”

Marco Phan (verified owner) –

Wow, this hand-held laser engraver is a game-changer! I used it to engrave intricate details on some jewelry pieces, and the precision was mind-blowing. It’s so easy to use, even for someone like me who’s just starting out in metalwork.

Soo Garcia –

★★★★★ Exceptional laser engraving quality & precision! User-friendly software & smooth operation. Fast engraving speed boosts productivity. Sturdy build, highly reliable.