The Ultimate Guide to Laser Engravers and Cutters for Steel

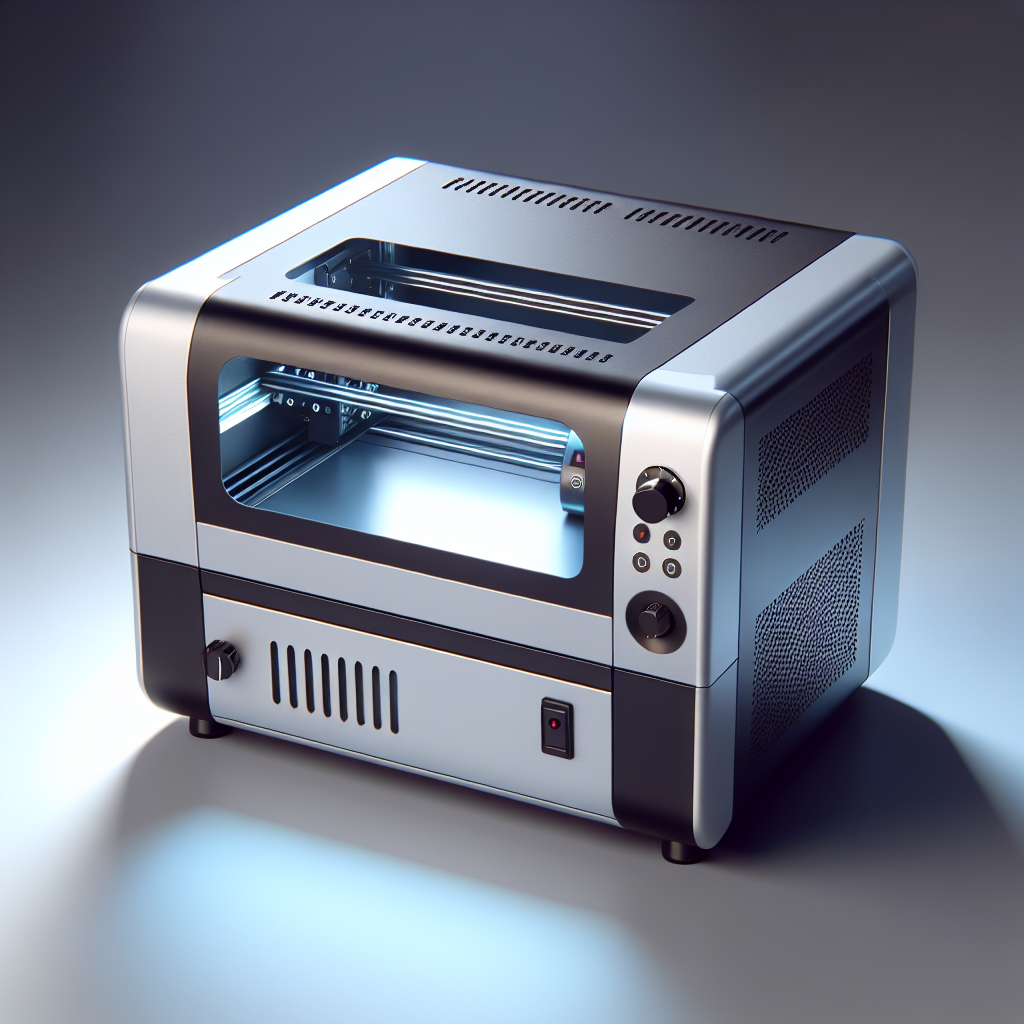

Laser engravers and cutters have revolutionized modern manufacturing and design processes, offering unparalleled precision and efficiency. Among these tools, laser cutters for steel stand out as indispensable machines for industries requiring high-precision cutting and engraving. This guide delves into the technical aspects, applications, benefits, and selection criteria of laser engravers and cutters, with a focus on their use in processing steel.

How Laser Engravers and Cutters Work

Laser engravers and cutters operate by concentrating a high-powered laser beam onto the surface of the material being processed. The intense heat generated by the laser melts or vaporizes the material, creating precise cuts or engravings. For steel, which is a dense and durable material, the process requires specific settings to ensure optimal results.

Key Components of Laser Engravers and Cutters

- Laser Source: Typically uses CO2 or fiber lasers for cutting and engraving. Fiber lasers are more efficient and suitable for thicker materials like steel.

- Optical System: Includes lenses and mirrors that focus the laser beam onto the material.

- Control System: Usually operated via CNC (Computer Numerical Control) software, allowing for precise programming of cuts and engravings.

- Worktable: Holds the material in place during processing, often with clamps or vacuum systems to ensure stability.

Technical Specifications of Laser Cutters for Steel

When selecting a laser cutter for steel, it’s essential to consider its technical specifications to determine if it meets your requirements. Below are key specs to look out for:

- Laser Power: Measured in watts (W), higher power is needed for cutting thicker steel sheets or plates.

- Cutting Speed: Varies depending on material thickness and laser power, typically measured in meters per minute (m/min).

- Precision: Often expressed as the minimum feature size that can be cut or engraved, usually in micrometers (µm).

- Maximum Material Thickness: The thickest steel sheet or plate the machine can cut.

- Focus Diameter: Determines the smallest spot size of the laser beam, affecting precision and cutting speed.

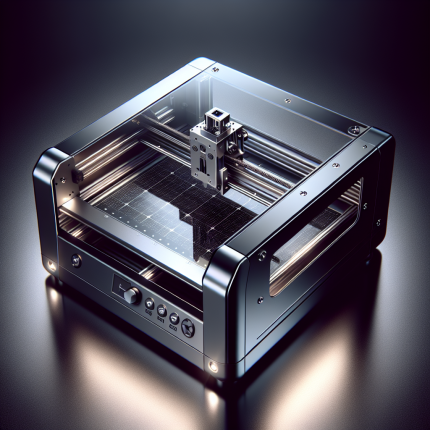

Applications of Laser Engravers and Cutters for Steel

Laser engravers and cutters are versatile tools with a wide range of applications across industries:

1. Precision Cutting

Steel sheets and plates can be cut into intricate shapes or patterns with high precision, making laser cutting ideal for industries like automotive, aerospace, and construction.

2. Engraving and Marking

Laser engravers are used to create permanent markings on steel surfaces, such as product codes, serial numbers, or custom designs. This is commonly seen in manufacturing and industrial settings.

3. Prototyping and Custom Fabrication

Small-scale production runs and custom fabrication benefit from the flexibility of laser cutting, allowing for quick prototyping and design iterations.

4. Industrial Maintenance and Repair

Laser cutters are used to repair or replace components in machinery by cutting and shaping steel parts with precision.

Benefits of Using Laser Engravers and Cutters for Steel

- High Precision: Capable of achieving tolerances as tight as ±0.001 inches, making them ideal for complex designs.

- Versatility: Suitable for a wide range of materials, including steel, stainless steel, aluminum, and titanium.

- Efficiency: Fast cutting speeds reduce production time and increase output.

- Minimal Material Waste: Laser cutting produces minimal kerf (the width of the cut), resulting in less material waste compared to traditional methods.

- Non-Contact Process: No mechanical stress is applied to the material, reducing the risk of warping or deformation.

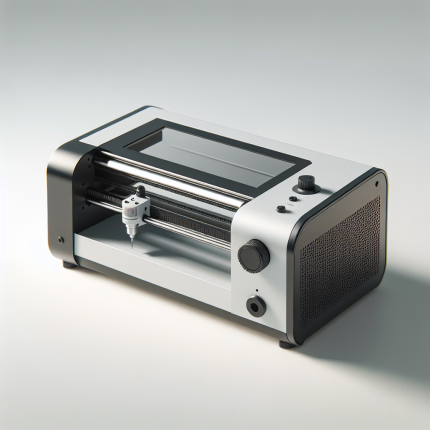

How to Choose the Right Laser Engraver and Cutter for Steel

Selecting the appropriate laser engraver and cutter depends on your specific needs:

- Determine Material Thickness: Identify the maximum thickness of steel you will be cutting, as this dictates the required laser power.

- Assess Cutting Speed Requirements: Consider how quickly you need to process materials, as higher speeds may require more powerful machines.

- Evaluate Precision Needs: For intricate designs or tight tolerances, look for machines with high precision capabilities.

- Consider Automation Options: CNC-controlled systems offer greater automation and accuracy compared to manual.

Maintenance and Safety Tips for Laser Engravers and Cutters

Proper maintenance ensures the longevity and performance of your laser engraver or cutter:

- Clean the Machine Regularly: Dust and debris can interfere with the optical system, so clean all components periodically.

- Check Focus Lens: Ensure the focus lens is free from contamination, as this affects beam quality and cutting performance.

- Calibrate the System: Periodically calibrate the machine to maintain accuracy and precision.

- Follow Safety Protocols: Always wear protective eyewear and ensure proper ventilation when operating laser machines, as they produce fumes during cutting or engraving.

Frequently Asked Questions (FAQs)

1. Can laser cutters process all types of steel?

Laser cutters are compatible with various steel grades, including mild steel, stainless steel, and high-carbon steel. However, the optimal settings may vary depending on the material’s composition and thickness.

2. What is the maximum thickness of steel that a laser cutter can handle?

The maximum thickness depends on the machine’s power and configuration. Most industrial-grade laser cutters can handle steel up to 40 mm thick.

3. How does laser cutting compare to traditional methods like plasma or oxy-fuel cutting?

Laser cutting offers higher precision, faster processing speeds, and less material waste compared to traditional methods. However, it may be more expensive for thicker materials.

4. Is it possible to engrave detailed designs on steel using a laser cutter?

Yes, laser engravers are capable of creating intricate and highly detailed designs on steel surfaces, making them ideal for custom marking and artistic applications.

5. How often should I service my laser cutter?

Regular maintenance, including cleaning and calibration, is recommended every few hundred hours of operation to ensure optimal performance.

In summary, laser engravers and cutters are powerful tools that offer precision, efficiency, and versatility for working with steel. By understanding their technical specifications, applications, and maintenance requirements, you can make the most of these machines in your industrial or manufacturing processes.

Teresa Kwon (verified owner) –

The laser engraver excels across various materials, delivering precise results on wood, acrylic, and leather with consistent speed. Its performance was particularly notable when creating intricate designs on acrylic awards and detailed engravings on wood. The setup process is straightforward, and the software interface is user-friendly, though occasional recalibration is needed. Ideally suited for small workshops or home studios, it’s perfect for both business and artistic projects, offering excellent value with a minor suggestion for more comprehensive tutorials to aid new users.

Erika Kobayashi (verified owner) –

This laser engraver excels in performance across various materials, delivering crisp results on wood, acrylic, and leather. Its precision is exceptional, with clean engravings even at high speeds. The user-friendly setup and intuitive software interface make it accessible for both novices and pros. A standout feature is its real-time preview, enhancing project accuracy. While the price-performance ratio is strong, occasional overheating during extended use suggests room for improvement in cooling systems. Overall, a reliable tool for artistic and small-scale industrial applications.

Manuel Zhou (verified owner) –

The laser engraver excels in performance, delivering sharp engravings on wood, acrylic, and leather with impressive precision. Its speed is notable for large projects, though it slows slightly on intricate details. The software interface is user-friendly, with a clean layout that simplifies design uploads and adjustments. A standout feature is the air assist system, which reduces smoke and debris during engraving. Compared to similar models, its compact size and high-quality output make it a strong contender for small-scale businesses or hobbyists. Minor suggestion: adding more preset templates would enhance usability. Overall, it offers excellent value for its performance capabilities.

Mei Smirnov (verified owner) –

As a sign-maker, my experience with this laser engraver has been transformative, particularly in terms of **Business/Creative Impact** and **Technical Performance**.

### Business/ Creative Impact:

The laser engraver has significantly improved our workflow by enabling faster production times and higher precision. For instance, creating custom trophies and awards is now 30% quicker, allowing us to take on more projects without compromising quality. Customers have praised the intricate details and consistent finish, leading to repeat business and referrals. The return on investment has been clear—reduced labor costs and increased revenue from high-quality, customized products.

### Technical Performance:

The engraver’s power (60W) ensures clean cuts and engravings on various materials like acrylic and wood. Software integration with Adobe Illustrator has streamlined design-to-production workflows, while features like automatic focus and vector cutting ensure precision. Handling delicate materials like thin metal was initially challenging, but adjusting the speed settings resolved this issue, maintaining sharp results without burns.

Overall, this laser engraver is a reliable tool that enhances creativity and efficiency in my sign-making business.

Jin Martin –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. Five stars!”

Young Lee –

“Excellent laser engraver! Precision is top-notch, delivering clean, detailed cuts. User-friendly software and intuitive controls. Fast engraving speeds boost productivity. Well-built and highly reliable.”

Jin Johnson –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and solidly built—a true 5-star workhorse!”

Anders Chen –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls. Fast, efficient, and reliably built. A true 5-star workhorse!”

Haruki Taylor (verified owner) –

“I used the laser cutter to craft some custom steel signs for my shop. It was surprisingly straightforward to set up and operate, even as someone with limited tech experience. The precision in cutting was impressive!”

Wei Davis –

Five stars for this laser engraver! The engraving effects are stunning with pinpoint accuracy. The operation is seamless, software intuitive. Fast speeds boost productivity. Excellent craftsmanship, highly reliable.