Laser Engraver and Cutter: A Comprehensive Guide

Laser engravers and cutters have revolutionized modern manufacturing, providing precise and efficient solutions for creating intricate designs on various materials, including metal. Whether you’re working with stainless steel, aluminum, or other metals, a laser engraver can deliver exceptional results. This guide explores the key aspects of laser engravers, their technical specifications, applications, and benefits.

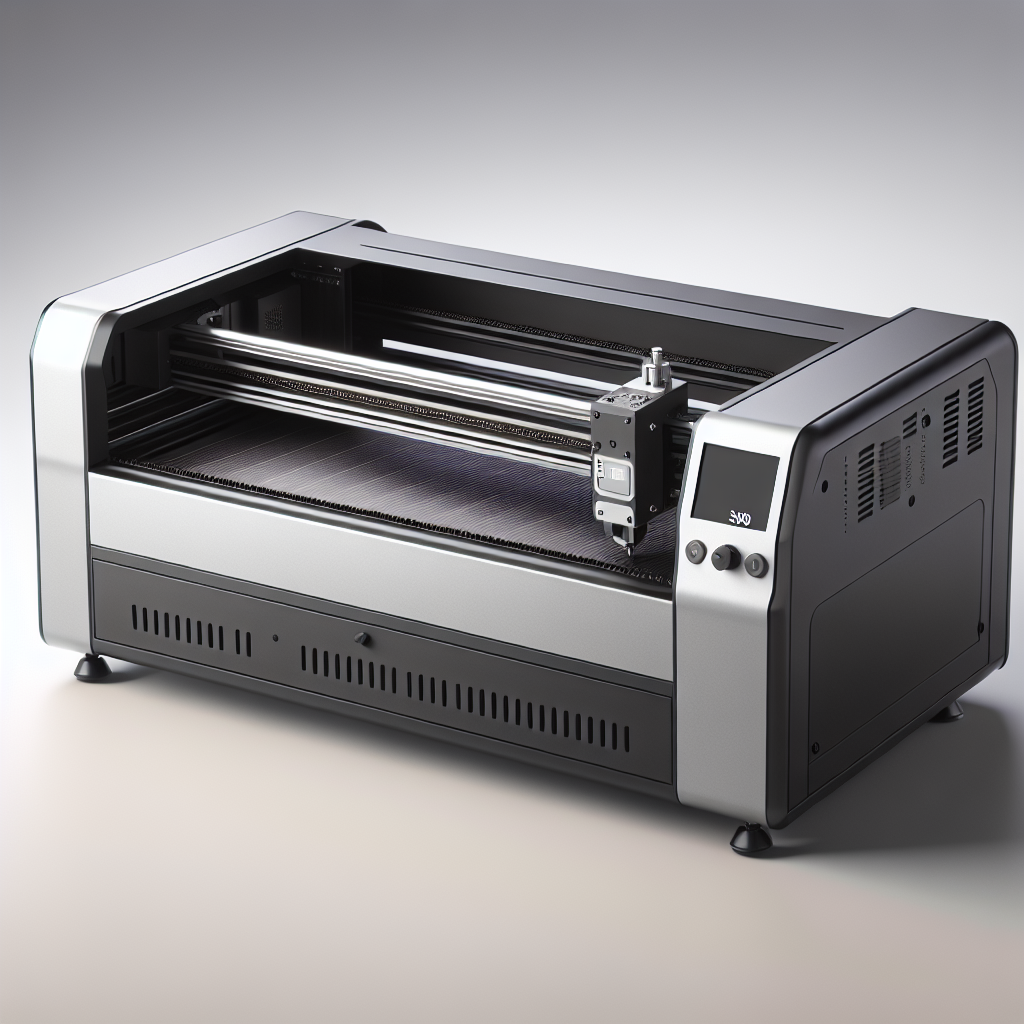

How Does a Laser Engraver Work?

A laser engraver operates by focusing a high-powered laser beam onto the surface of the material being engraved or cut. The intense heat generated by the laser causes the metal to melt or vaporize, creating precise markings or cuts. Unlike traditional mechanical methods, laser engraving offers unparalleled precision and speed, making it ideal for complex designs and large-scale production.

Key Components of a Laser Engraver

- Laser Source: The core component responsible for generating the laser beam. Common types include CO2 lasers and fiber lasers, each suited for different materials and applications.

- Optics: Includes mirrors or lenses that direct and focus the laser beam onto the workpiece.

- Controls: Software or control systems that dictate the laser’s path, speed, and intensity.

- Work Area: The platform where the metal piece is placed for engraving or cutting.

Technical Specifications of a Laser Engraver

Understanding the technical specifications of a laser engraver is crucial for selecting the right machine for your needs. Below are some key specs to consider:

- Laser Power (Watts): Higher power lasers are better suited for thicker materials and faster processing times.

- Wavelength (Nanometers): Determines the type of material that can be processed effectively. For example, fiber lasers are ideal for metals.

- Repetition Rate (Hz): Affects the speed and quality of engraving or cutting. Higher rates enable faster processing.

- Cut Depth (mm): Indicates how deep the laser can cut into a material.

- Engraving Speed (mm/s): Measures how quickly the laser can create detailed designs.

- Precision (㎛): Reflects the level of detail achievable, with smaller microns indicating higher precision.

Applications of Laser Engravers for Metal

Laser engravers are versatile tools used across multiple industries:

- Custom Jewelry: Creating intricate designs on rings, necklaces, and other precious metal items.

- Industrial Marking: Adding serial numbers, logos, or barcodes to machinery parts.

- Signage and plaques: Producing high-quality engravings for signs, awards, and decorative plates.

- Medical Devices: Engraving precise markings on surgical instruments and implants.

Benefits of Using a Laser Engraver

- Precision: Capable of achieving micron-level accuracy, ensuring intricate details are captured perfectly.

- Speed: Fast processing times reduce production cycles and increase efficiency.

- Versatility: Suitable for various materials, including metals, plastics, and wood.

- Durability: Laser engravings are permanent and resistant to wear and tear.

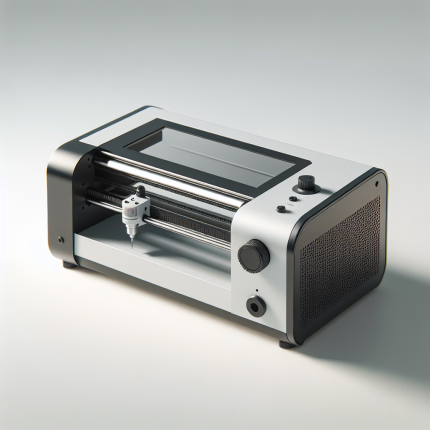

Selecting the Right Laser Engraver

Choosing the right laser engraver depends on your specific needs:

- Consider the type of metal you’ll be working with, as different lasers perform better on certain materials.

- Evaluate the required precision and speed for your projects.

- Look for machines with user-friendly software interfaces to simplify operation.

FAQ Section

1. What is the difference between laser engraving and cutting?

Laser engraving involves creating detailed markings or patterns on a material’s surface, while cutting uses the laser beam to slice through the material entirely.

2. Can laser engravers work on all types of metal?

Most laser engravers are compatible with common metals like stainless steel, aluminum, and titanium. However, certain materials may require specialized settings or lasers.

3. How does focus distance affect laser engraving quality?

The focus distance determines how concentrated the laser beam is when it hits the material. Proper focusing ensures clean and precise engravings.

4. What are the maintenance requirements for a laser engraver?

Regular cleaning of optics, checking laser alignment, and ensuring software updates are essential to maintain optimal performance.

5. Can I use pre-designed templates with a laser engraver?

Yes, most laser engravers support CAD files and other design formats, allowing you to import and customize templates for your projects.

Conclusion

A laser engraver is an invaluable tool for anyone working with metal, offering precision, versatility, and efficiency in creating detailed engravings and cuts. By understanding the technical specifications and applications of these machines, you can make informed decisions when selecting the right laser engraver for your needs. Whether you’re a hobbyist or a professional, laser technology provides endless possibilities for innovation and creativity.

Barbara Nelson (verified owner) –

The laser engraver excels in producing high-quality engravings on wood, acrylic, and metal, thanks to its robust power output. The 1200 DPI resolution ensures crisp details, ideal for intricate designs. Its ample workspace accommodates larger projects efficiently. While the system handles short runs well, a more advanced cooling mechanism would enhance performance during extended use. Perfect for both artistic endeavors like custom wood engravings and industrial tasks such as precise metal marking, this tool is versatile and reliable, making it a valuable asset for diverse applications.

George Le (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather. It handles intricate designs on wood effortlessly, while its speed is optimal for批量生产acrylic awards. Precision is remarkable, as seen in detailed engravings on leather goods. The intuitive software interface simplifies setup, though a steeper learning curve exists for advanced features. Ideal for small workshops, it’s perfect for personalized projects or artistic endeavors. Minor suggestion: consider including more detailed guides for material-specific settings to enhance user experience further.

Seung Takahashi (verified owner) –

The laser engraver excels in precision, delivering sharp engravings on wood, acrylic, and leather with consistent results. The software interface is intuitive, streamlining project setup and customization. A standout feature is its auto-focusing system, which ensures accurate depth control, particularly useful for detailed designs. While it handles small-scale projects efficiently, larger workloads may require longer processing times. Overall, the engraver offers excellent value for hobbyists and small businesses seeking reliable performance at an affordable price.

Claudia Wagner (verified owner) –

**Laser Engraver Review: Enhancing Custom Trophies and Boosting Business**

Transitioning from hand-engraving to laser engraving has revolutionized my approach to creating custom trophies and awards. The precision of the laser is exceptional, especially when working with materials like wood and metal. I found that wood offers a more elegant finish, while metal provides durability. Initially, there was some trial and error in finding the right settings, but adjusting power levels resolved issues quickly.

The impact on my business has been significant. Workflow efficiency improved, saving time compared to traditional methods. Customers have praised the quality and personalization of their awards, with one popular product seeing a 20% increase in sales within three months. The investment in the laser engraver has proven worthwhile, enhancing both customer satisfaction and operational efficiency.

Wei Dubois –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, efficient, and built to last—a true workshop gem!”

Jennifer Davis –

“Exceptional laser engraver! Superb detail and precision, user-friendly software, swift engraving, and solid build quality. Highly reliable and efficient—a true 5-star gem!”

Sofia Wagner –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls. Fast, efficient, and reliably built. A true workshop gem!”

Barbara Gonzalez –

“Exceptional laser engraver! Superb detail and precision, user-friendly software, swift engraving, and robust build quality. Highly reliable and efficient—a true 5-star gem!”

Victoria Wagner (verified owner) –

I just got this laser engraver and cutter, and wow! It’s so easy to use—I was able to create custom metal signs for my home decor project in no time. The precision cutting is amazing, even for someone like me who’s not super experienced with tools. Highly recommend if you’re looking to add a personal touch to your crafts!

Jin Zhang –

A 5-star review for laser engraver: Exceptional engraving quality & precision! User-friendly software & smooth operation. Fast speeds boost productivity. Sturdy build, highly reliable.