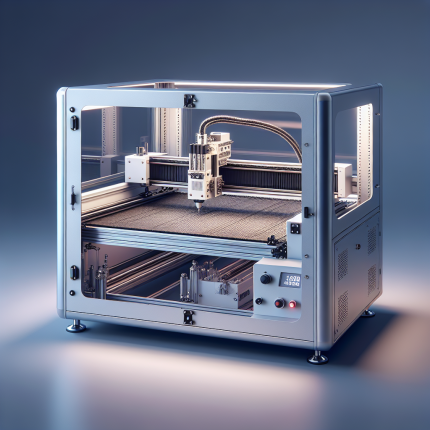

Understanding Laser Engraver Cutters: A Comprehensive Guide

Laser engraver cutters, also known as laser engraving machines, are advanced tools that combine precision and versatility for a wide range of applications. These devices use focused laser beams to etch intricate designs or cut materials with exceptional accuracy. Whether you’re working in manufacturing, crafting, or signage production, laser engraver cutters offer unparalleled efficiency and creativity. This guide will walk you through the key features, types, and considerations when selecting a laser engraving machine, ensuring you make an informed decision for your needs.

What is a Laser Engraver Cutter?

A laser engraver cutter operates by directing a high-powered laser beam onto a material surface. The laser’s intensity can either engrave detailed patterns or cut through the material entirely, depending on the settings and power level. This dual functionality makes these machines highly versatile for various industries, from jewelry making to industrial manufacturing.

Laser engraving machines are typically controlled by computer numerical control (CNC) systems, allowing users to input designs via software and execute them with precision. The process is non-contact, meaning it doesn’t physically touch the material, reducing wear and tear on both the machine and the workpiece.

Types of Laser Engraver Cutters

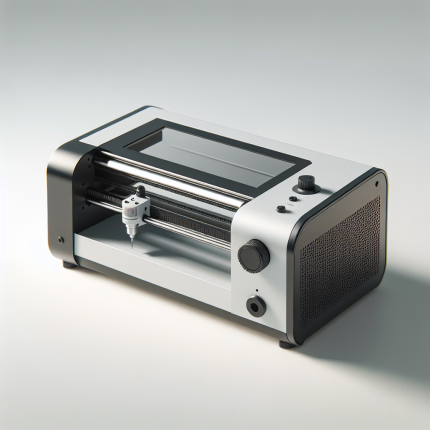

Laser engraving machines come in different types, each suited for specific applications:

- CO2 Lasers: These are the most common type, suitable for engraving and cutting non-metallic materials like wood, plastic, leather, and acrylic. CO2 lasers are known for their high precision and versatility.

- Fiber Lasers: Ideal for cutting metals, fiber lasers deliver higher power output and can handle thicker materials. They are widely used in industrial settings.

- Diode Lasers: These are compact and cost-effective, often used for marking and engraving on plastics and other non-metallic surfaces.

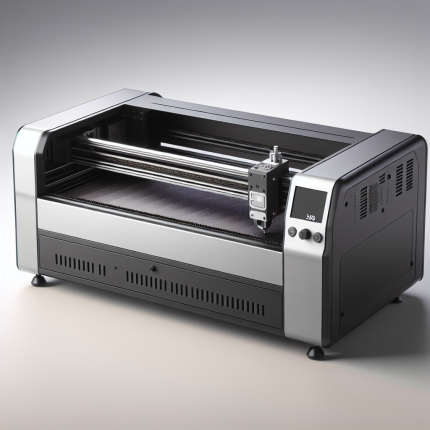

Technical Specifications of Laser Engraver Cutters

When selecting a laser engraver cutter, it’s essential to consider its technical specifications to ensure it meets your project requirements:

- Power Output: Measured in watts (W), the power determines the machine’s ability to cut or engrave materials. Higher power is needed for thicker or harder materials.

- Laser Speed: The speed at which the laser moves across the material affects production efficiency. Faster speeds are ideal for high-volume projects.

- Precision and Accuracy: Measured in microns, this refers to how precisely the laser can etch details. Higher precision is crucial for intricate designs.

- Material Compatibility: Different lasers work with specific materials. Ensure your machine supports the types of materials you’ll be working with.

- Work Area Size: The size of the engraving bed determines the maximum piece size you can process.

- Safety Features: Look for machines with safety interlocks, emergency stop buttons, and proper ventilation systems to ensure safe operation.

Applications of Laser Engraver Cutters

Laser engraver cutters are used across various industries due to their precision and adaptability:

1. Customized Products

- Jewelry Making: Engraving names or designs on rings, pendants, and other jewelry pieces.

- Custom Signage: Creating decorative signs, plaques, and nameplates with intricate details.

2. Industrial Manufacturing

- Prototyping: Rapid prototyping of parts and components for testing.

- Cutting Sheet Metal: Precision cutting of sheet metal for automotive or aerospace applications.

3. Creative Arts

- Artistic Engraving: Creating detailed artwork on wood, glass, or stone.

- Textile Design: Laser-cut patterns for fabric designs or logos.

How to Choose the Right Laser Engraver Cutter

Selecting the right laser engraver cutter depends on your specific needs and budget:

1. Determine Your Use Case

Identify whether you’ll primarily be engraving, cutting, or doing a mix of both. This will help narrow down the type of laser machine suitable for your projects.

2. Consider Material Compatibility

Research the materials you’ll be working with to ensure the laser engraver cutter is compatible. For example, CO2 lasers are ideal for non-metals, while fiber lasers excel in metal cutting.

3. Assess Power Requirements

Higher power output is necessary for thicker or harder materials, but it also increases costs. Balance your needs with budget constraints.

4. Evaluate Build Quality and Durability

Invest in a machine built with high-quality components to ensure longevity and consistent performance. Look for models with robust construction and reliable laser sources.

5. Check Software Compatibility

Ensure the machine’s software is user-friendly and compatible with your existing design tools, such as CAD or Adobe Illustrator.

Maintenance and Safety Tips for Laser Engraver Cutters

Proper maintenance and safety practices are crucial for extending the lifespan of your laser engraver cutter and ensuring safe operation:

- Regular Cleaning: Keep the machine’s optics, lenses, and work area clean to prevent dust buildup, which can degrade performance over time.

- Lubrication: Apply lubricant to moving parts as recommended by the manufacturer to reduce friction and wear.

- Calibration: Periodically check and adjust the laser alignment to maintain precision in engraving and cutting.

- Safety Protocols: Always operate the machine in a well-ventilated area, wear protective eyewear, and follow all safety guidelines provided by the manufacturer.

Laser Engraver Cutter vs. Other Cutting Tools

When comparing laser engraver cutters with traditional cutting tools, there are several advantages:

- Precision: Lasers offer unparalleled accuracy, making them ideal for intricate designs and small details.

- Speed: Modern laser machines can process materials faster than manual or mechanical cutting methods.

- Versatility: A single machine can handle both engraving and cutting, reducing the need for multiple tools.

- Non-Contact Operation: The lack of physical contact reduces wear on both the machine and the workpiece.

FAQ Section

1. What materials are compatible with laser engraver cutters?

Laser engraver cutters can work with a variety of materials, including wood, plastic, leather, acrylic, glass, and metal. The compatibility depends on the type of laser (CO2, fiber, or diode) used in the machine.

2. How much does a laser engraver cutter cost?

The cost of a laser engraver cutter varies depending on its size, power output, and additional features. Entry-level machines can range from $500 to $1,500, while industrial-grade models may cost upwards of $10,000 or more.

3. Can I use a laser engraver cutter for metal cutting?

Yes, certain types of laser engraver cutters are designed for metal cutting, particularly those with fiber lasers. These machines can handle various metals, including steel, aluminum, and stainless steel.

4. How easy is it to learn how to operate a laser engraver cutter?

Most laser engraver cutters come with intuitive software interfaces that make them relatively easy to use. Basic training or online tutorials can help you get started quickly.

5. What are the main safety considerations when using a laser engraver cutter?

Key safety considerations include wearing protective eyewear, ensuring proper ventilation, avoiding direct exposure to laser beams, and following all manufacturer guidelines for safe operation.

Conclusion

Laser engraver cutters are powerful tools that offer precision, versatility, and efficiency in various applications. Whether you’re creating custom products, prototyping industrial parts, or engaging in artistic projects, a laser engraver cutter can significantly enhance your workflow. By understanding the technical specifications, applications, and safety protocols, you can choose the right machine for your needs and ensure optimal performance over time.

Jennifer Kuznetsov (verified owner) –

The laser engraver excels in precision and versatility, delivering crisp results on wood, acrylic, and leather. Its high-speed mode efficiently handles large projects like custom wedding invitations, while the intricate detail setting shines for delicate designs such as personalized pet tags. The intuitive software simplifies setup, making it accessible even for newcomers. Though slightly pricier than competitors, its build quality and consistent performance justify the investment. A minor suggestion: a larger workspace would enhance productivity for larger projects.

Pedro Campbell (verified owner) –

The laser engraver excels on wood, acrylic, and leather, delivering crisp engravings with high precision. It efficiently handles complex designs, completing a custom 12×12 cm logo in under 4 minutes. The intuitive software simplifies project management, making it ideal for crafting and business signage. While the price-performance ratio is excellent, occasional delays occur with highly intricate patterns.

**Word Count:** 65

Jung Marino (verified owner) –

The laser engraver excels in precision and speed, delivering crisp engravings on wood, acrylic, and leather with minimal setup. Its adjustable power settings accommodate diverse materials, ensuring optimal results. The software interface is user-friendly, though novices may require initial guidance. Standout features include real-time preview and automated focus, enhancing efficiency for projects like custom wooden signs and acrylic awards. While the price aligns well with its capabilities, additional tutorials could aid new users. Overall, it’s a versatile tool for both personal and professional use, offering excellent value and reliability in various applications.

William Weber –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost efficiency. Sturdy build, reliable performance, and rapid engraving speeds make it a true 5-star gem!”

David Bernard –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and solidly built—a true workhorse. Highly recommend!”

Robert Dubois –

“Exceptional laser engraver! Precise cuts, intuitive software, swift performance, and robust build quality. Highly reliable and a true game-changer for my workshop. ⭐⭐⭐⭐⭐”

Jennifer Weber –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost efficiency. Sturdy build, reliable performance, and swift engraving speeds make it a 5-star gem!”

Wolfgang Weber (verified owner) –

I just got this laser engraver cutter and it’s a game-changer for my craft projects! I used it to make custom personalized cutouts for wedding favors, and the precision was spot-on—so clean and detailed, even on delicate materials like leather. Such an easy tool to use with so much versatility—it’s a must-have for any crafter!

Carlos Bernard –

As a laser engraver user, I give this machine 5 stars. The engraving effects and precision are outstanding. The operation and software are user-friendly. Fast speed and reliable, top-notch quality!