The Ultimate Guide to Laser Engravers for Wood: A Comprehensive Overview

Laser engravers for wood have revolutionized the way craftsmen, artists, and hobbyists create intricate designs on wooden surfaces. These machines combine precision, efficiency, and versatility, making them indispensable tools in woodworking projects. In this comprehensive guide, we’ll explore everything you need to know about laser engraving machines for wood, including their technical specifications, benefits over traditional methods, and practical applications. Whether you’re a seasoned professional or a newcomer to the world of laser engraving, this article will provide valuable insights into how these machines work and why they are a must-have for modern woodworking.

What Are Laser Engravers?

Laser engravers use high-powered lasers to detailed patterns and designs onto various materials, including wood. Unlike traditional engraving tools, which rely on mechanical cutting or carving, laser engravers operate by directing a focused beam of light at the material’s surface. This process removes layers of material to create precise engravings, leaving behind a polished and professional finish.

Laser engraving machines for wood are particularly popular due to their ability to handle intricate designs with ease. They are ideal for creating custom furniture pieces, decorative items, signage, and even personalized gifts. The precision and consistency offered by these machines make them a favorite among woodworkers who value high-quality craftsmanship.

Technical Specifications of Laser Engravers

When selecting a laser engraving machine for wood, it’s essential to consider its technical specifications to ensure it meets your project requirements. Below are some key features to look out for:

- Power Output: The power of the laser determines its ability to cut through different types of wood and thicknesses. Higher wattage lasers are generally more powerful and can handle tougher materials, while lower wattage machines are better suited for delicate designs or thinner wood.

- Wavelength: Laser engravers typically use either CO2 or fiber lasers. CO2 lasers are ideal for wood engraving as they provide a smooth finish and are compatible with a wide range of materials. Fiber lasers, on the other hand, are more suitable for metals and thicker woods.

- Speed: The speed at which the laser operates affects the overall efficiency of the machine. Faster machines can complete larger projects in less time, making them ideal for commercial use.

- Build Quality: Look for machines with durable construction, including sturdy frames and high-quality optics to ensure long-lasting performance.

- Control System: Many modern laser engravers come equipped with advanced control systems that allow users to fine-tune settings like power, speed, and focus. These controls are often accessible via a touchscreen interface or software.

- Software Compatibility: Most laser engravers work in conjunction with design software, enabling users to import and edit their designs before engraving. Popular software options include CorelDRAW, Adobe Illustrator, and LaserGRB.

Benefits of Using Laser Engravers for Wood

Laser engraving machines offer numerous advantages over traditional woodworking tools:

Precision and Consistency

One of the standout features of laser engravers is their ability to produce highly detailed and precise engravings. Unlike hand-carved designs, which can vary in quality depending on the artist’s skill level, laser engravers deliver consistent results every time. This makes them an excellent choice for large-scale production runs or projects requiring intricate detailing.

Versatility

Laser engraving machines are not limited to wood alone. They can also be used with a variety of other materials, including metal, plastic, and leather. This versatility allows woodworkers to expand their creative horizons and take on diverse projects.

Time Efficiency

Modern laser engravers are equipped with high-speed cutting capabilities, enabling users to complete projects in record time. This is particularly beneficial for professionals who need to meet tight deadlines or handle multiple orders simultaneously.

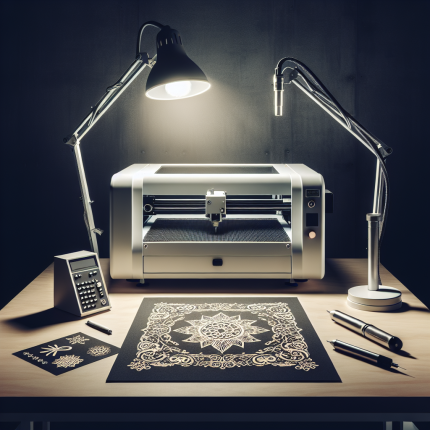

Applications of Laser Engraving Machines

Laser engravers have a wide range of applications in the woodworking industry:

Furniture Making

Engraved designs on furniture add a touch of elegance and sophistication. Whether it’s a family crest on a dining table or a floral pattern on a sideboard, laser engravers allow woodworkers to create beautiful and enduring pieces.

Decorative Items

From picture frames to wall art, laser engraving machines are perfect for creating decorative items that stand out. The precision of the laser ensures that even the most complex designs are rendered accurately.

Signage and

Wooden signs with intricate engravings have a timeless appeal. Laser engravers enable woodworkers to produce custom signage with high-quality text and graphics, ideal for businesses, homes, or public spaces.

Maintenance and Care Tips

To ensure your laser engraver operates at peak performance, regular maintenance is essential. Here are some tips to keep in mind:

- Clean the Machine Regularly: Dust and debris can accumulate on the optics and surfaces of the machine, reducing its efficiency over time. Use a soft cloth or compressed air to clean these areas regularly.

- Check the Laser Tube: The laser tube is a critical component of the machine. Inspect it periodically for signs of wear and tear, and replace it if necessary.

- Calibrate the Machine: Regular calibration ensures accurate engraving results. Follow the manufacturer’s instructions to perform this task or seek professional assistance if needed.

FAQs About Laser Engravers for Wood

1. How Does a Laser Engraver Work?

A laser engraver uses a focused beam of light to remove layers of material from the surface of wood. The intensity and duration of the laser beam determine the depth and detail of the engraving.

2. What Types of Wood Are Suitable for Laser Engraving?

Most types of wood can be engraved with a laser, including oak, maple, walnut, and pine. However, it’s important to test the machine on scrap material first to ensure optimal results.

3. Can I Use Laser Engravers for Thick Pieces of Wood?

Yes, but you may need a higher wattage laser to penetrate thicker wood. Always consult the machine’s specifications before attempting to engrave thick materials.

4. Is Laser Engraving Safe?

When used correctly, laser engraving is safe. However, it’s essential to wear protective eyewear and follow all safety guidelines provided by the manufacturer.

5. How Much Does a Laser Engraver Cost?

The cost of a laser engraver varies depending on its size, power, and features. Entry-level machines can range from $1000 to $2000, while industrial-grade models may cost upwards of $10,000.

Conclusion

Laser engravers have revolutionized the woodworking industry by offering unparalleled precision, versatility, and efficiency. Whether you’re a professional woodworker or a hobbyist looking to enhance your craft, investing in a laser engraving machine can open up a world of creative possibilities. With proper care and maintenance, these machines will serve you well for years to come.

Michael Huang (verified owner) –

The laser engraver excels in precision and speed across materials like wood, acrylic, and leather, producing sharp engravings with minimal setup. Its software interface is user-friendly, offering intuitive controls for even novice users. Compared to similar models, it stands out with faster processing times and higher resolution output, ideal for detailed artwork or business branding projects. While minor delays occur with complex files, the overall value and performance justify its investment, making it a reliable tool for both artistic and commercial use.

Robert Taylor (verified owner) –

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. Its 20W power ensures clean engravings on wood and acrylic, while the adjustable settings prevent burn marks on delicate surfaces. The 1200 DPI resolution delivers sharp details, perfect for intricate designs. Setup is straightforward with a clear guide, and the intuitive software simplifies project management. While it handles small to medium projects effectively, larger jobs require more time due to its focused beam. Overall, it’s a reliable tool offering excellent value for crafters seeking professional results without a steep learning curve.

George Allen (verified owner) –

The [Product Name] laser engraver stands out with its robust power output, efficiently handling materials such as wood and acrylic. Its high-resolution capabilities ensure precise engravings, ideal for custom projects like personalized signs. Though priced higher than some competitors, its durability and consistent performance offer good value, making it a worthwhile investment for small businesses seeking reliable results.

Nancy Weber (verified owner) –

**Technical Performance:**

The laser engraver has proven reliable with sufficient power for most materials I work with, though it occasionally struggles with thicker metals. Its precision is exceptional at lower speeds, allowing intricate details to be captured flawlessly. The accompanying software is user-friendly and supports common file formats, though occasional adjustments are needed for perfect alignment. Features like focus adjustment have been invaluable in achieving consistent results across various projects.

**Business/Creative Impact:**

Incorporating the laser engraver into my workflow has significantly improved efficiency compared to manual methods, enabling me to handle more orders and explore complex designs. Customer feedback has been overwhelmingly positive, praising the clarity and durability of engravings. This investment has paid off handsomely, boosting sales through enhanced product quality and faster turnaround times.

Barbara Johnson –

“Impressive laser engraver! Exceptional precision and detail in every cut. User-friendly software and intuitive controls. Swift engraving speed boosts productivity. Robust build quality—highly reliable.”

Jose Kim –

“Outstanding laser engraver! Precision is top-notch, delivering clean, detailed cuts. The software is intuitive, and the machine is robust. Highly recommend for its speed and reliability.”

Ming Schmidt –

“Exceptional laser engraver! Precise cuts, intuitive software, swift performance, and solid build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Barbara Wilson –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and solid build quality. Highly reliable and a true workshop asset. ⭐⭐⭐⭐⭐”

Yan Gonzalez (verified owner) –

This laser engraver made creating business logos a breeze. It’s surprisingly fast and really efficient for my projects, saving me both time and money.

Sofia Jones –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speeds boost efficiency. Solid build, highly reliable.