Laser Engraving Cutting Machine: A Comprehensive Guide

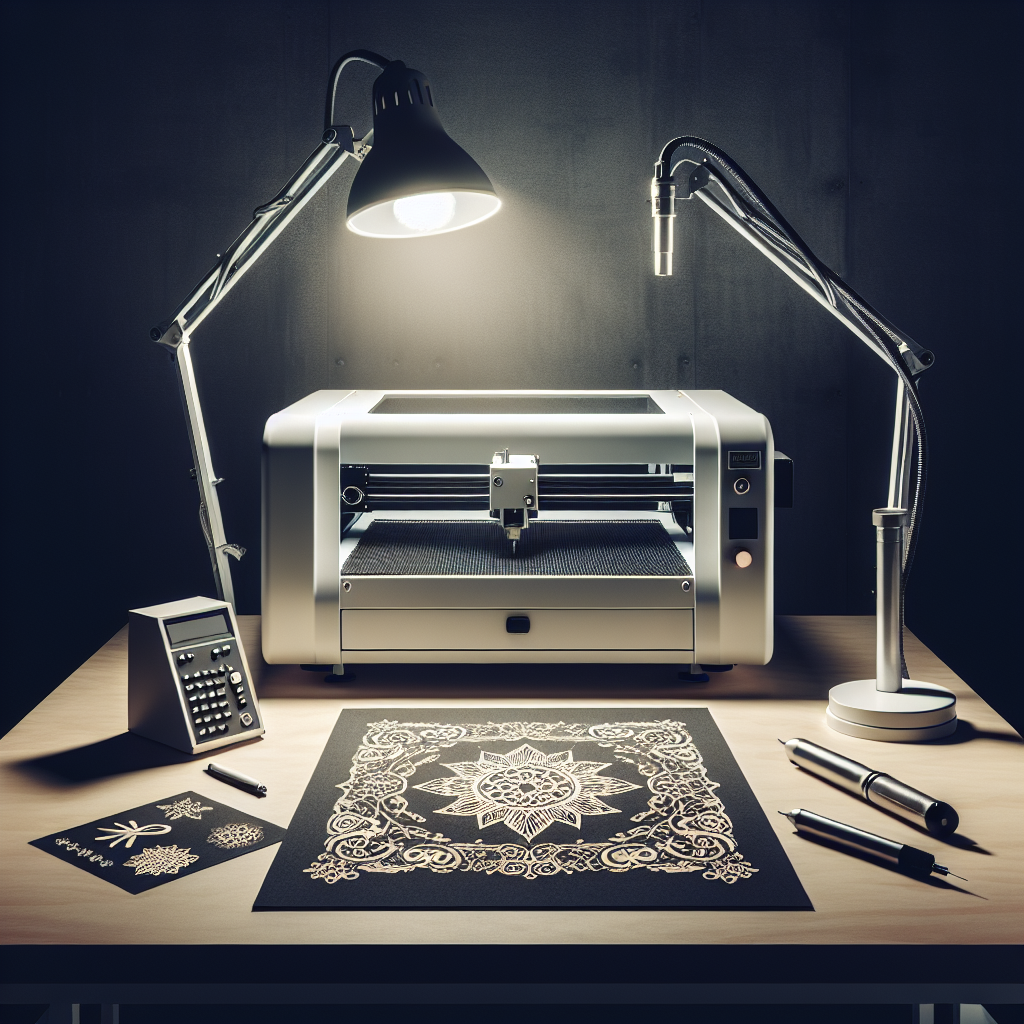

Laser engraving cutting machines have become a popular tool for both professionals and hobbyists looking to create precise and intricate designs. These machines combine the power of laser technology with advanced software to produce high-quality engravings and cuts on various materials. Whether you’re working on a small DIY project or running a professional workshop, an at-home laser cutter machine can be a game-changer. In this guide, we’ll explore everything you need to know about laser engraving cutting machines, including their technical specifications, benefits, and considerations for purchasing one.

What is a Laser Engraving Cutting Machine?

A laser engraving cutting machine uses a focused beam of light to etch or cut through materials like wood, metal, plastic, and glass. Unlike traditional tools, these machines offer unparalleled precision and flexibility. They are commonly used in industries such as woodworking, jewelry making, sign-making, and even electronics manufacturing. For home users, laser engraving cutting machines open up a world of possibilities for creating personalized items, custom designs, and small-scale production runs.

Benefits of Using a Laser Engraving Cutting Machine

- Precision: Laser technology ensures clean and accurate cuts or engravings, even on delicate materials.

- Versatility: These machines can work with a wide range of materials, making them suitable for various projects.

- Speed: Compared to manual cutting or engraving, laser machines significantly reduce production time.

- Customization: With the right software, you can create complex designs and patterns that are difficult to achieve manually.

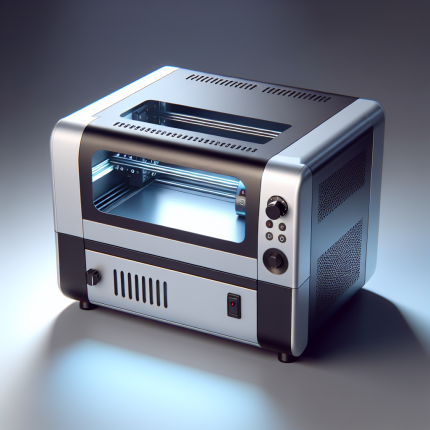

Technical Specifications of Laser Engraving Cutting Machines

When shopping for a laser engraving cutting machine, it’s essential to consider its technical specifications to ensure it meets your project requirements. Below is an overview of key specs:

- Power Output: Measured in watts (W), the power output determines the machine’s ability to cut or engrave through different materials. Higher wattage machines are suitable for thicker or harder materials.

- Laser Type: Common types include CO2, fiber, and diode lasers. Each type has its advantages depending on the material being worked on.

- Build Quality: Look for machines with durable construction, especially in the frame and moving parts, to ensure longevity.

- Software Compatibility: Ensure the machine is compatible with popular design software like CorelDRAW or Adobe Illustrator.

- Cutting Area: The size of the cutting area determines the maximum project size you can work on.

- Safety Features: Look for machines with safety guards, emergency stop buttons, and automatic shutdown features to protect users.

Key Considerations When Choosing a Laser Engraving Cutting Machine

1. Material Compatibility

Before purchasing, research which materials your machine can handle. For example, CO2 lasers are ideal for wood, plastic, and acrylic, while fiber lasers are better suited for metal cutting.

2. Budget

Laser engraving machines vary widely in price, from affordable entry-level models to high-end industrial-grade units. Determine your budget and prioritize features that align with your project needs.

3. Space Requirements

Consider the physical footprint of the machine. If you’re setting it up at home, ensure there’s enough space for both the machine and any additional tools or materials.

4. Ease of Use

Look for machines with user-friendly interfaces and intuitive software. Some models come with pre-loaded templates, making them easier to use for beginners.

Frequently Asked Questions (FAQs)

1. Is a laser engraving cutting machine safe to use at home?

Yes, most modern laser engraving machines are designed with safety in mind. They include features like emergency stop buttons and safety guards to minimize risks. However, always follow the manufacturer’s guidelines for operation and maintenance.

2. How much does an at-home laser cutter cost?

The price of a laser engraving cutting machine varies depending on its specifications and brand. Entry-level models can range from $500 to $1,500, while professional-grade machines can cost upwards of $5,000 or more.

3. What materials can I cut with a laser engraving machine?

Common materials include wood, plastic, acrylic, leather, glass, and metal. The type of laser (e.g., CO2 vs. fiber) will determine the range of materials you can work with.

4. Do I need special training to operate a laser cutter?

While some models are designed for beginners, it’s always a good idea to familiarize yourself with the machine’s features and safety protocols before use. Many manufacturers offer online tutorials or user manuals to help you get started.

5. Can I upgrade my laser engraving machine in the future?

Yes, many laser machines allow for upgrades such as increasing power output, expanding cutting area, or adding new software features. Check with the manufacturer for compatible options.

Conclusion

A laser engraving cutting machine is a versatile and powerful tool that can transform your at-home projects into professional-quality creations. By understanding its technical specifications, benefits, and key considerations, you can make an informed decision when choosing the right machine for your needs. Whether you’re a hobbyist or a small-scale producer, investing in a laser engraving cutting machine is sure to elevate your work to new heights.

If you have more questions or need further assistance, feel free to explore additional resources or consult with professionals in the field. Happy creating!

Alexei Walker (verified owner) –

The laser engraver excels in precision and versatility, effortlessly handling wood, acrylic, and leather. Its high-speed processing ensures quick turnaround on projects like custom wooden signs and intricate acrylic ornaments. The user-friendly interface simplifies setup, even for novices, while the dual-axis system enhances creativity. However, a more detailed safety guide would be beneficial. Overall, it’s a cost-effective solution for small businesses and hobbyists seeking reliable performance and versatility.

Claudia Nakamura (verified owner) –

**Laser Engraver Experience: Specific Project & Business Impact**

**1. Specific Project Experience:**

I utilized the laser engraver for a custom gift item line featuring personalized wooden tags. The birchwood material responded well, producing crisp, high-contrast engravings even on intricate designs. A challenge arose with minor warping due to heat, which was resolved by adjusting engraving speed and using clamps for stability.

**2. Business/Creative Impact:**

The laser engraver streamlined production, reducing setup time from 30 minutes to just 5 minutes per design. Customer feedback highlighted the premium quality of engravings, leading to increased orders. The tool provided a quick ROI within six months, enhancing both efficiency and customer satisfaction.

Richard Smith –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably built. Highly recommend!”

Hiroshi Rodriguez –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and well-crafted—a true 5-star workhorse!”

Anders Bernard –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost efficiency. Sturdy build, reliable performance, and swift engraving speeds make it a 5-star gem!”

Maria Martinez –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts efficiency. Well-built and highly reliable. ⭐⭐⭐⭐⭐”

Yan Phillips (verified owner) –

I used this laser cutter at home to make custom keychains with our names engraved. It was super easy and precise—definitely worth getting for personalized projects!

Marco Martin –

★★★★★ Excellent Laser Engraver! Impressive etching precision & quality. User-friendly software & smooth operation. Fast engraving speed boosts productivity. Sturdy build, highly reliable.