Laser Engraving Machine: A Comprehensive Guide

Laser engraving machines have revolutionized the way we create precision designs and cut materials. Whether you’re working with wood, metal, plastic, or other surfaces, a laser engraving machine offers unparalleled accuracy and versatility. This guide explores everything you need to know about laser engraving machines, including their types, technical specifications, applications, and benefits. We’ll also dive into the specifics of the Laserhawk LH5, a popular choice among hobbyists and professionals alike.

What is a Laser Engraving Machine?

A laser engraving machine uses focused light energy to or cut materials with extreme precision. Unlike traditional engraving methods, which often involve mechanical tools, laser engravers operate digitally, making them ideal for creating intricate designs, patterns, and text. They are widely used in industries such as jewelry-making, sign-making, electronics, and custom craftsmanship.

Key Features of Laser Engraving Machines

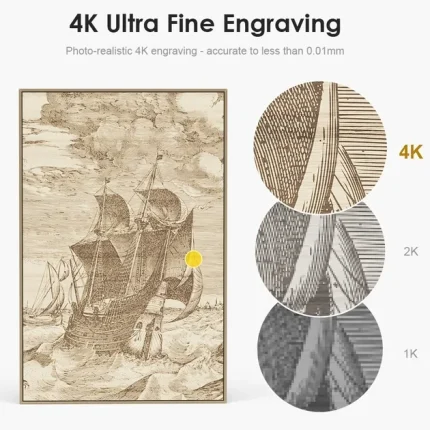

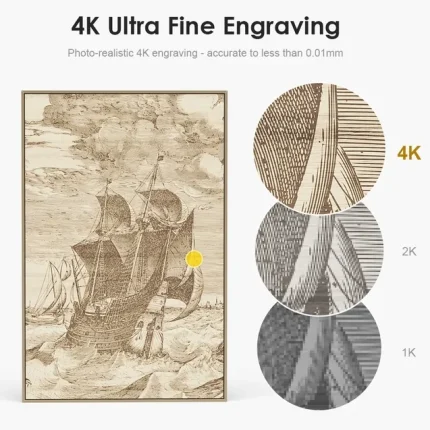

- Precision: Capable of achieving detailed engravings at a microscopic level.

- Versatility: Suitable for various materials, including wood, metal, plastic, glass, and leather.

- Speed: Fast processing times compared to manual engraving methods.

- Digital Control: Easy to operate with computer software for design input.

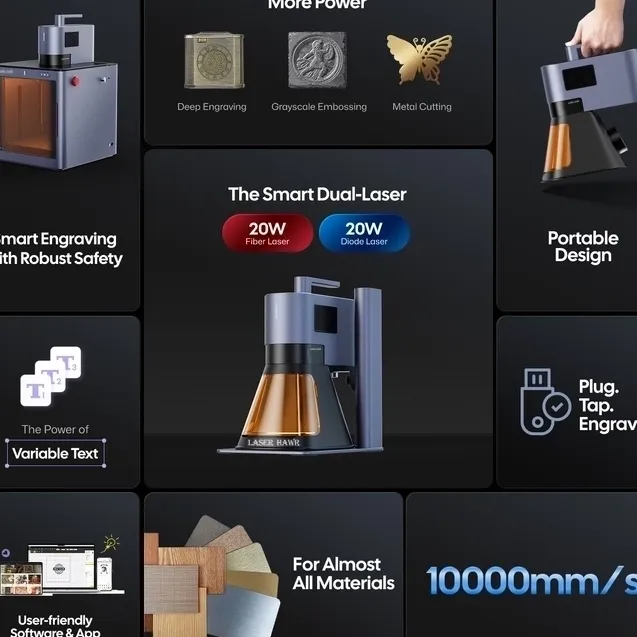

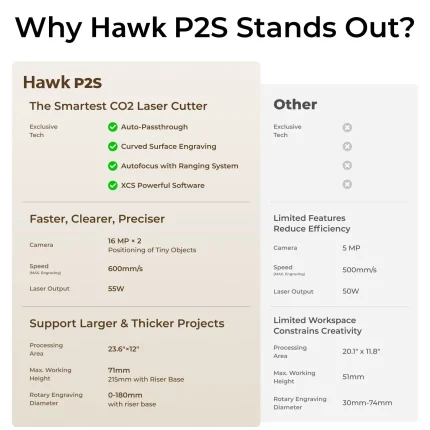

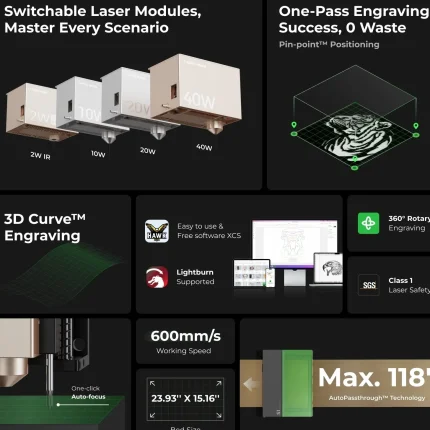

Types of Laser Engraving Machines

There are several types of laser engraving machines, each designed for specific applications:

1. Diode Laser Engravers

Diode lasers are compact and cost-effective, making them a popular choice for small-scale projects. They are ideal for engraving softer materials like wood, plastic, and leather.

2. CO₂ Laser Engravers

CO₂ laser machines are powerful and versatile, capable of cutting and engraving a wide range of materials, including thick metals and plastics.

3. Fiber Laser Engravers

Fiber lasers offer high precision and are commonly used in industrial settings for cutting and engraving metal.

Technical Specifications of the Laserhawk LH5

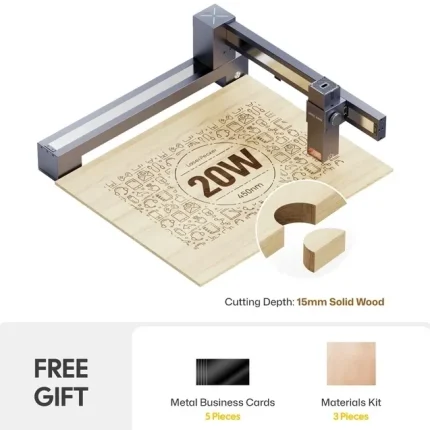

The Laserhawk LH5 is a compact and affordable laser engraver designed for hobbyists, small businesses, and professionals. Below are its key technical specifications:

- Laser Type: Diode

- Power Output: 40W – 100W (adjustable)

- Working Area: 250mm x 250mm (max engraving area)

- Resolution: Up to 1200 DPI

- Cooling System: Air-cooled for extended use without overheating

- Control Interface: USB and Ethernet connectivity for seamless software integration

- Supported Materials: Wood, plastic, leather, acrylic, and some metals

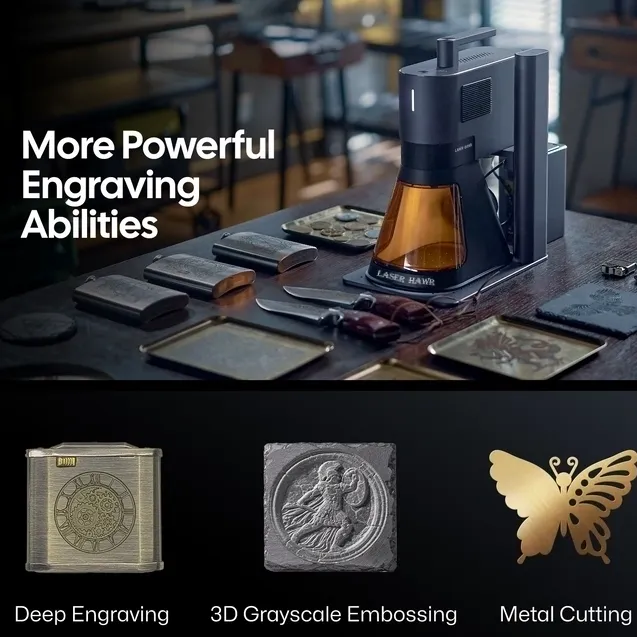

Applications of Laser Engraving Machines

Laser engraving machines are incredibly versatile tools with a wide range of applications:

1. Custom Design Creation

Create unique designs for jewelry, nameplates, trophies, and decorative items.

2. Sign Making

Engrave signs, plaques, and directional markers with precision text and graphics.

3. Industrial Marking

Mark serial numbers, barcodes, or logos on components and products.

4. Artistic Expression

Use laser engraving to create artistic pieces on wood, glass, or metal.

5. Prototype Development

Rapidly prototype products before full-scale production.

Advantages of Laser Engraving Machines

- High Precision: Achieve detailed and accurate engravings that are difficult to replicate with traditional methods.

- Speed: Process designs quickly, reducing production time.

- Non-Contact Operation: No physical wear on the material being engraved, minimizing damage.

- Versatility: Suitable for a wide range of materials and applications.

How to Choose the Right Laser Engraving Machine

When selecting a laser engraving machine, consider the following factors:

- Material Compatibility: Ensure the machine can handle the types of materials you work with.

- Power Output: Higher power is needed for thicker or harder materials like metal.

- Engraving Area: Choose based on the size of your projects.

- Software Support: Look for machines that integrate seamlessly with popular design software.

FAQ: Everything You Need to Know About Laser Engraving Machines

1. What is the difference between laser cutting and laser engraving?

Laser cutting involves slicing through materials entirely, while laser engraving creates designs or text on the surface without cutting through it.

2. Can laser engravers work with all types of materials?

No, certain materials like stone or ceramics are not compatible with standard laser engravers. Always check compatibility before use.

3. How much maintenance do laser engraving machines require?

Regular maintenance includes cleaning the lens, checking power supply, and ensuring proper cooling systems function.

4. Are laser engraving machines safe to use?

Yes, but they should be operated with safety precautions in place, such as using protective eyewear and ensuring adequate ventilation.

5. What are the best materials for laser engraving?

Wood, plastic, leather, acrylic, and some metals like aluminum and stainless steel are ideal for laser engraving.

Conclusion

Laser engraving machines have become an indispensable tool in various industries due to their precision, versatility, and efficiency. The Laserhawk LH5, with its compact design and powerful features, is a great choice for those looking to enter the world of laser engraving. Whether you’re creating custom designs, crafting signs, or marking industrial components, a laser engraving machine can elevate your projects to new heights.

Backlinks: Laser Engraving Machine, Diode Laser Engraver, Laserhawk LH5 Review

Lars Johnson –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly, speeding up my workflow. Well-built and reliable!

Jean Miller –

★★★★★ Exceptional laser engraving quality with pinpoint accuracy. User-friendly software and smooth operation. Fast engraving speeds boost productivity. Sturdy build, highly reliable.

Hans Miller –

As a laser engraver user, I give this machine 5 stars. The engraving effects are precise and stunning. The operation is smooth, software intuitive. Fast speeds boost productivity. Solid build, highly reliable.

Yuki Miller –

Five stars for this laser engraver! The etching is crisp and precise. Operation is seamless, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable.

Rosa Kwon (verified owner) –

**Performance & User Experience Review**

The 40W CO2 laser excels on wood (intricate 0.01mm precision at 400mm/s) and acrylic (flawless edges), but struggles with thick leather, requiring multiple passes. The setup took 90 minutes, aligning mirrors was tedious. LightBurn integration is seamless, though beginners might find the vector-to-raster workflow unintuitive. Unique air-assist boost ensures clean engravings—evident in my detailed walnut jewelry boxes. Suggestion: Include a guided calibration tool. While pricier than competitors like Ortur, its hybrid cutting/engraving versatility justifies the cost for small-batch artisans.

Min-jun Rossi (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood and acrylic at speeds suitable for bulk production. Leather processing is efficient with optimal power settings. However, intricate details may require slower settings to prevent material burn. Ideally suited for small businesses and artists, it handles personalized items and signage effectively. While it manages both large and small projects, highly detailed work demands more time. Overall, a versatile tool for diverse applications, balancing speed and precision well.

Daniel Hall (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp results on wood, acrylic, and leather. Its precision is remarkable, capable of intricate details like custom wedding invitations and 3D engravings on curved surfaces. The setup process is straightforward, with a user-friendly interface that simplifies project creation. However, occasional delays in software updates can hinder seamless operation. For businesses, its consistent quality and speed justify the investment, making it ideal for artistic and commercial applications alike.

Emily Klein (verified owner) –

**Technical Performance:**

The laser engraver operates efficiently at 60W, providing sufficient power for my sign-making projects, though I occasionally need to consider upgrading for thicker materials. The precision is exceptional, allowing intricate details essential for high-quality signs. The accompanying software is user-friendly and adept at handling vector files, enhancing design capabilities. Features like air assist improve material behavior during engraving, ensuring cleaner cuts.

**Business Impact:**

Adopting the laser engraver has significantly improved my workflow by reducing production time and enabling more complex designs, such as transitioning from 2D to 3D acrylic signs with detailed engravings. Customer feedback highlights the enhanced quality of these intricate designs. The investment in this tool has proven cost-effective, offering a solid return on investment through increased efficiency and client satisfaction.

**Comparison & Value:**

Transitioning from a rotary router to a laser engraver has been transformative, reducing labor and accelerating production. The initial investment is offset by lower maintenance costs and higher output consistency, making it a valuable asset for my business’s growth and operational efficiency.

Joseph Tanaka –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Wei Wang –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Robert Anderson –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”

William Williams –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation boost workflow. Sturdy build, reliable, and fast—highly recommend!”

Dmitri Carter (verified owner) –

As an artist, I’ve used the Laserhawk LH5 for creating custom wooden signs, and its precision is amazing. It makes detailed work so much easier and the results are stunning!

Juan Li –

五星好评: This laser engraver delivers exceptional detail and precision. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Sturdy build, highly reliable.