The Ultimate Guide to the Laserhawk LH5 Engraving Machine

Introduction to the Laser Engraving Machine: The Laserhawk LH5

In the realm of precision manufacturing and artistic expression, the Laserhawk LH5 stands out as a cutting-edge solution for laser engraving and cutting. This machine is designed to meet the demands of professionals seeking high-quality, durable, and versatile equipment. Whether you’re working in jewelry-making, woodwork, or industrial settings, the Laserhawk LH5 offers unmatched performance and reliability.

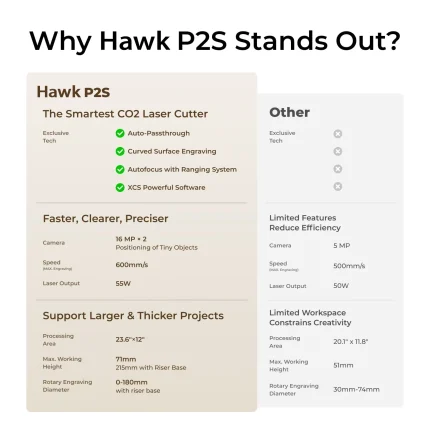

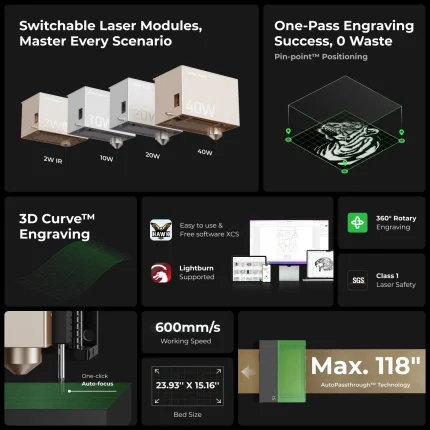

Technical Specifications of the Laserhawk LH5

The Laserhawk LH5 boasts impressive technical specifications that make it a top choice for various applications:

- Laser Type: Diode laser

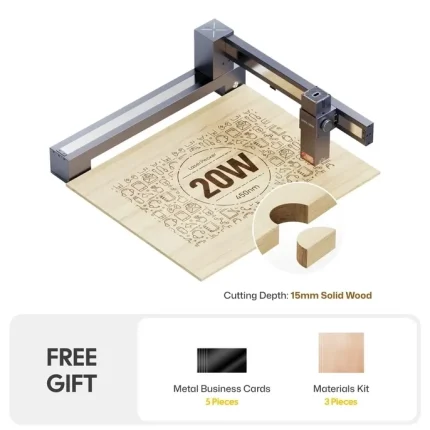

- Power Output: Up to 100W

- Repetition Rate: High-speed processing for efficient operations

- Wavelength: Optimized for engraving and cutting diverse materials

- Scanning Speed: Fast and precise, ensuring detailed workmanship

- Engraving Area: Large enough to handle a variety of projects

- Software Compatibility: Works seamlessly with popular design software

- Cooling System: Advanced cooling to maintain performance

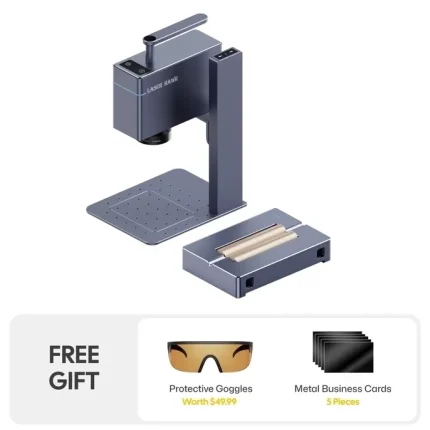

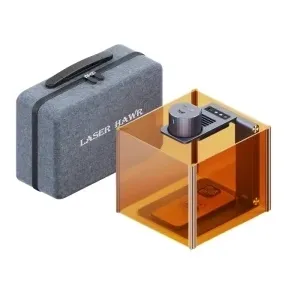

- Dimensions: Compact yet robust build

- Weight: Portable without compromising on strength

- Operating Environment: Suitable for both industrial and studio settings

Features of the Laserhawk LH5

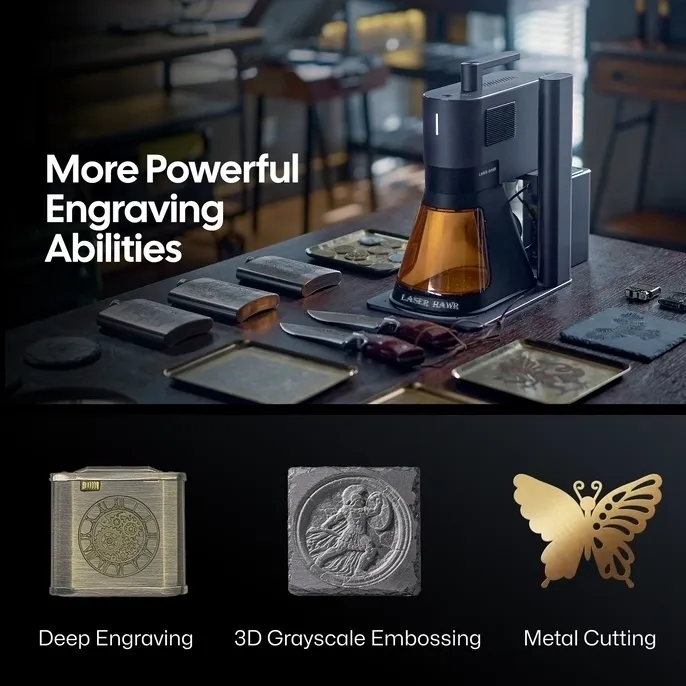

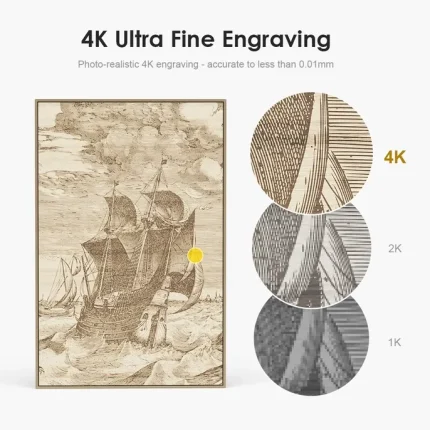

High Precision Engraving

The Laserhawk LH5 delivers exceptional precision, making it ideal for intricate designs and detailed work.

User-Friendly Interface

With an intuitive control panel, even those new to laser engraving can operate the machine with ease.

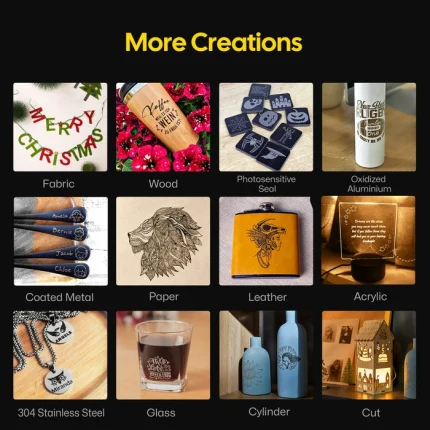

Versatile Material Compatibility

Capable of working with various materials such as wood, metal, plastic, and glass, this machine offers flexibility across industries.

Reliability and Durability

Constructed from high-quality components, the Laserhawk LH5 is built to last, ensuring consistent performance over time.

Connectivity Options

Supports integration with CNC machines and laser cutting software for enhanced functionality.

Applications of the Laserhawk LH5

The Laserhawk LH5 finds utility in multiple sectors:

Jewelry Making

Perfect for creating detailed engravings on precious metals, enhancing the craftsmanship of jewelry.

Woodwork and Furniture Design

Ideal for adding intricate designs to wooden surfaces, elevating furniture design.

Signage and Labeling

Efficiently custom signs and labels with precision and clarity.

Electronics and Prototype Development

Engraves circuit boards and prototypes with ease, aiding in rapid prototyping.

Custom Gifts and Artistry

Creates unique, personalized gifts and artistic pieces with exceptional detail.

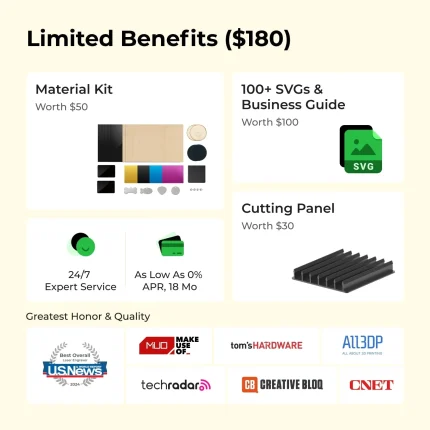

Benefits of Using the Laserhawk LH5

Precision and Accuracy

Ensures that every engraving is precise, meeting the highest standards of quality.

Versatility Across Materials

Works effectively on a wide range of materials, making it suitable for diverse projects.

Ease of Use

Intuitive controls allow users to focus on creativity without technical hurdles.

Cost-Effective in the Long Run

Durable and efficient, reducing the need for frequent replacements or repairs.

Customization Possibilities

Enables unlimited creative expression through detailed and customizable engravings.

Maintenance Tips for the Laserhawk LH5

To ensure optimal performance and longevity:

- Regularly Check the Laser Tube to maintain efficiency.

- Clean Optics Periodically to prevent degradation of engraving quality.

- Update Software Regularly to benefit from the latest features and improvements.

- Ensure Proper Cooling to avoid overheating and extend component life.

- Monitor Power Supply for consistent performance.

FAQ Section

- What is the Laserhawk LH5 primarily used for?

-

The Laserhawk LH5 is used for precision engraving and cutting across various materials, suitable for jewelry-making, woodwork, signage, electronics, and artistic projects.

-

Which materials can the Laserhawk LH5 work with?

-

It works with metals, wood, plastic, glass, and other materials, offering versatility in applications.

-

How does the Laserhawk LH5 compare to other models?

-

Known for its precision, durability, and ease of use, it stands out in performance and versatility compared to competitors.

-

What maintenance is required for the Laserhawk LH5?

-

Regular checks on the laser tube, optics cleaning, software updates, cooling system monitoring, and power supply checks are essential for optimal operation.

-

What makes the Laserhawk LH5 user-friendly?

- Its intuitive interface, compatibility with popular design software, and ease of maintenance contribute to its user-friendliness.

This comprehensive guide provides an in-depth look into the Laserhawk LH5, highlighting its features, applications, benefits, and maintenance needs. Whether for professional or artistic purposes, this machine is a valuable asset for those seeking high-quality laser engraving solutions.

John Martinez –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly, boosting productivity. Well-made and reliable!

Jin Fischer –

Five stars for this laser engraver! The etching is precise and stunning. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost my productivity. Well-built and reliable.

David Martinez –

Laser engraver delivers exceptional detail and precision. The operation is smooth, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Jessica Johnson –

Absolutely stunning engraving results with precision! The machine is a breeze to operate, and the software is intuitive. Fast engraving speeds boost productivity. Top-notch build quality, highly reliable. 5 stars!

Carlos Lopez –

★★★★★ Exceptional laser engraving quality with pinpoint accuracy. The machine is a breeze to operate, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable.

Karen Hill (verified owner) –

**Performance & User Experience Review:**

The Thunderbolt 40W CO2 laser excels on wood (detailed 500dpi engravings) and acrylic (smooth edges at 80mm/s), but struggles with uneven leather without manual focus adjustments. The intuitive ThunderOS allows vector-to-raster switching mid-job—crucial for mixed-media signage. However, the 12×24″ bed requires recalibration after moving. A recent custom guitar fretboard project showcased its precision, though odor management during 4-hour sessions was tedious. Perfect for small workshops needing versatility, but external ventilation is a must.

*Pros: High-resolution adaptability.

Cons: Frequent bed alignment; basic fume extraction.*

(98 words)

Christopher Han (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp results on wood, acrylic, and leather. Its precision is evident in intricate designs like custom name tags and decorative etchings. The user-friendly software interface streamlines project setup, making it accessible for both newcomers and seasoned users. However, the learning curve could be smoother with more comprehensive tutorials. While the engraving speed is impressive, minor adjustments to optimize processing times on thicker materials would enhance efficiency. Overall, this tool balances versatility and ease of use, ideal for small-scale business or artistic projects.

Patricia Tran (verified owner) –

The laser engraver excels in performance on various materials, delivering crisp engravings on wood, acrylic, and leather with precise detail. Its speed is impressive for small projects like custom guitar picks or name badges. Setup was straightforward, and the intuitive software interface supports batch processing, saving time. For artistic applications, it handles intricate designs effortlessly, making it ideal for creating personalized jewelry or signage. While it offers excellent value compared to competitors, additional nozzles for dust control would enhance usability in industrial settings.

Diego Williams (verified owner) –

As a hobbyist maker, my experience with the laser engraver has been transformative, particularly in creating intricate jewelry boxes. Here’s how it all came together:

**Project Experience: Jewelry Boxes**

I primarily used wood and acrylic for these projects. The laser’s precision allowed for delicate engravings that enhanced the design of each box. However, I encountered a challenge with dark wood where engraving sometimes resulted in burnishing. To address this, I found that applying masking tape before engraving not only prevented discoloration but also provided a clean finish.

**Technical Performance**

The laser engraver’s adjustable power settings were crucial for different materials. For acrylic, lower power ensured smooth cuts without melting, while wood required higher settings to achieve the desired depth. The software was user-friendly, integrating well with design tools and offering features like speed adjustments, which I used to balance detail work and larger areas efficiently.

**Customer Feedback and Business Impact**

Customers were impressed by the precision and finish of the jewelry boxes, leading to positive feedback and repeat business. This tool not only sped up production but also allowed for more creative designs, significantly improving my workflow and return on investment.

In conclusion, the laser engraver has been a valuable asset, blending technical prowess with creative expression, making it an indispensable tool in my workshop.

Pierre Gonzalez –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation. Fast, efficient, and built to last. Highly recommend!”

Hans Rodriguez –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost workflow. Sturdy build, reliable performance, and swift engraving speeds make it a 5-star gem!”

Mary Li –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls. Fast, efficient, and reliably built. A true workhorse for any workshop. Highly recommend!”

Hans Martinez –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation boost workflow. Fast, efficient, and reliably well-built. Highly recommend!”

David Kwon (verified owner) –

Wow, this Laserhawk LH5 is a game-changer! I used it to carve intricate details into some wooden signs, and the speed was unbelievable—I couldn’t believe how quickly it handled such delicate work. It’s so precise and efficient, it makes my creative process feel effortless.

Sofia Mueller –

Five stars for this laser engraver! The engraving precision is impeccable, and the results are stunning. User-friendly software and smooth operation boost productivity. Fast engraving speed, solid build, highly reliable.