Laser Metal Engraving Machine: A Comprehensive Guide

Laser metal engraving machines have revolutionized the manufacturing and artistic industries by offering precise, efficient, and durable engraving solutions. These machines utilize advanced laser technology to etch intricate designs onto various metals, including stainless steel, aluminum, titanium, and more. Whether you’re a hobbyist, an artist, or a business owner, understanding how these machines work, their technical specifications, and their applications can help you unlock endless possibilities for your projects.

In this guide, we’ll explore everything you need to know about laser metal engraving machines, including their key features, benefits, and how they compare to other engraving methods. We’ll also dive into the technical aspects, such as power output, speed, and precision, to help you make an informed decision for your needs.

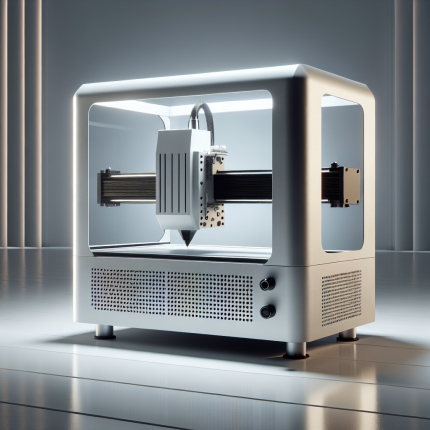

What is a Laser Metal Engraving Machine?

A laser metal engraving machine is a device that uses focused laser beams to create permanent engravings on metallic surfaces. Unlike traditional mechanical engraving methods, which rely on rotating bits or needles, laser engraving machines operate with high-powered lasers that remove material by melting or vaporizing it. This process results in highly detailed and accurate designs that are resistant to wear and tear.

Laser metal engraving machines are widely used in industries such as jewelry making, automotive manufacturing, aerospace, electronics, and art. They offer unparalleled precision and versatility, making them a popular choice for both small-scale projects and large-scale production runs.

How Does a Laser Metal Engraving Machine Work?

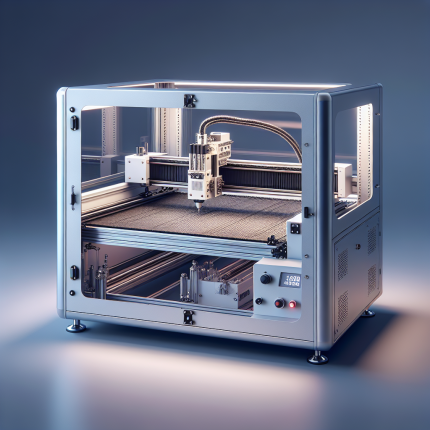

The operation of a laser metal engraving machine involves several key components: the laser source, the focusing optics, the motion control system, and the software interface. Here’s an overview of how these machines work:

- Laser Source: The laser generates a highly concentrated beam of light energy. The most common types of lasers used in metal engraving are CO2 lasers and fiber lasers. Fiber lasers are particularly popular for metal engraving due to their high power efficiency and ability to produce deep engravings.

- Focusing Optics: The laser beam is focused through a lens or mirror system to create an intensely narrow spot on the material’s surface. This concentrated energy enables precise control over the engraving process.

- Motion Control System: The machine uses stepper motors or servo drives to move the laser head across the workpiece, following the design programmed into the software. This ensures that the engraving is executed with pinpoint accuracy.

- Software Interface: The machine’s software allows users to import designs from CAD files, adjust settings such as laser power and speed, and preview the engraving before it begins.

By combining these elements, a laser metal engraving machine can create complex patterns, text, and images on metal surfaces with remarkable detail and consistency.

Technical Specifications of Laser Metal Engraving Machines

When selecting a laser metal engraving machine, it’s essential to consider its technical specifications to ensure it meets your project requirements. Below are some key features to look for:

- Laser Power: Measured in watts (W), the laser power determines the depth and speed of the engraving. Higher power lasers are better suited for thicker or harder materials.

- Engraving Speed: This refers to how quickly the machine can etch a design, measured in inches per second (IPS). Faster speeds are ideal for large-scale production.

- Precision: The accuracy of the engraving is typically measured by the laser spot size, which determines the smallest detail that can be engraved. A smaller spot size allows for more intricate designs.

- Material Compatibility: Most laser metal engraving machines are compatible with a variety of metals and alloys. Check the machine’s specifications to ensure it supports your desired materials.

- Software Compatibility: Ensure the machine is compatible with popular design software such as Adobe Illustrator, CorelDRAW, or Fusion 360 for seamless workflow integration.

Applications of Laser Metal Engraving Machines

Laser metal engraving machines are incredibly versatile and can be used in a wide range of applications across different industries. Some common uses include:

- Custom Jewelry: Creating personalized engravings on rings, bracelets, necklaces, and other jewelry pieces.

- Industrial Marking: Etching serial numbers, barcodes, or logos onto tools, machinery, and components for identification and traceability.

- Artistic Expression: Designing intricate metal sculptures, decorative plates, and custom artwork.

- Automotive Industry: Engraving vehicle identification numbers (VINs), badges, and interior trim pieces.

- Electronics: Marking circuit boards, housings, and other components with fine details.

The ability to create durable and highly detailed engravings makes laser metal engraving machines a valuable tool for both industrial and artistic purposes.

Benefits of Using Laser Metal Engraving Machines

- Precision and Accuracy: Laser engraving offers unmatched precision, allowing for intricate designs that are difficult or impossible to achieve with traditional methods.

- Speed and Efficiency: Modern laser metal engraving machines can complete projects quickly, reducing production time and increasing throughput.

- Durability: The engravings created by these machines are resistant to wear and tear, ensuring long-lasting results.

- Versatility: Laser metal engraving machines can handle a wide range of materials and project sizes, making them suitable for diverse applications.

- Non-Contact Process: Unlike mechanical engraving, laser engraving does not physically touch the material, reducing the risk of damage or deformation.

Frequently Asked Questions (FAQ)

1. What materials can a laser metal engraving machine work with?

Laser metal engraving machines are primarily designed for use on metals such as stainless steel, aluminum, titanium, and brass. Some models may also support non-metallic materials like acrylic, glass, or wood, depending on the laser type and power settings.

2. Can I engrave deep into metal using a laser machine?

Yes, modern laser metal engraving machines are capable of creating deep engravings, especially when equipped with high-power fiber lasers. The depth of the engraving depends on factors such as laser power, material thickness, and engraving speed.

3. Is laser metal engraving suitable for?

Absolutely! Laser metal engraving machines are highly efficient and can handle large-scale production runs with consistent quality and precision. Many models also support automation features to streamline the manufacturing process.

4. Do I need special training to operate a laser metal engraving machine?

While some basic knowledge of laser technology and CAD software is helpful, most laser metal engraving machines are user-friendly and come with comprehensive manuals or tutorials to guide operators through setup and use.

5. How much maintenance do these machines require?

Laser metal engraving machines typically require regular maintenance to ensure optimal performance. This includes cleaning the optics, checking for wear on moving parts, and ensuring proper cooling systems are functioning. However, with routine upkeep, these machines can last for many years.

Conclusion

Laser metal engraving machines have become an indispensable tool for anyone looking to create precise, durable, and visually striking engravings on metal surfaces. With their versatility, precision, and efficiency, these machines offer a wide range of applications across industries such as jewelry making, industrial manufacturing, and artistic creation. By understanding the technical specifications, benefits, and applications of laser metal engraving machines, you can make an informed decision when selecting the right machine for your needs.

John Brown (verified owner) –

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. Engraving intricate designs on wooden signs was seamless, while acrylic cuts were clean with minimal burn marks. The software interface is user-friendly, simplifying complex projects for even novice users. A standout feature is the real-time preview, allowing adjustments before engraving. However, thicker materials occasionally require multiple passes. Compared to competitors, this model offers better speed and accuracy at a competitive price, making it ideal for both small businesses and hobbyists seeking reliable performance without compromise.

Margaret Horvat (verified owner) –

The laser engraver excels in precision and speed across materials like wood and acrylic, delivering sharp engravings effortlessly. Its 60W power and 1200 DPI resolution ensure detailed work, ideal for custom signs or intricate jewelry. Setup is straightforward, and the intuitive software simplifies project management. While it handles leather well, occasional overheating can occur with thicker materials. The price-performance ratio is strong, offering excellent ROI for small businesses, though additional dust collection would enhance long-term usability.

Jessica Hernandez (verified owner) –

**Experience with Laser Engraver: A Professional Woodworking Artist’s Perspective**

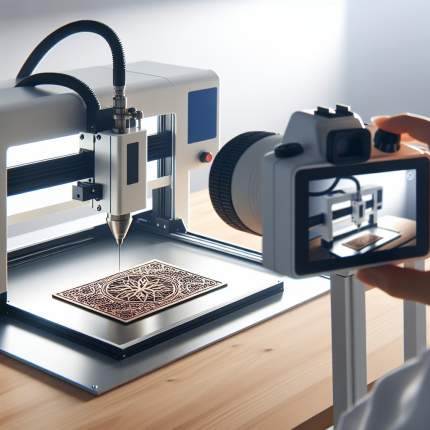

**1. Specific Project Experience: Custom Trophies and Awards**

– **Materials Used**: The laser engraver proved versatile, handling both wood and metal effectively. For wooden trophies, the engraving was smooth and detailed, while metals required precise power adjustments to achieve optimal results without burn marks.

– **Precision in Details**: The machine excelled in creating intricate designs on different materials. A notable project involved a client requesting fine details on both wood and metal plaques, which the laser handled seamlessly with adjusted settings for each material.

– **Challenges and Solutions**: Engraving curved surfaces was initially challenging due to uneven results. By adjusting the focal length and using specialized software features, I achieved consistent quality across all curves.

**2. Technical Performance**

– **Power and Precision**: The laser’s power was sufficient for various projects, delivering precise engravings that met high-quality standards. This capability was crucial for maintaining detail integrity in both wood and metal.

– **Software Experience**: The software interface was user-friendly, allowing efficient design transfer with minimal learning curve. Utilizing special features like multi-layered engravings enhanced project complexity and added a touch of elegance to the final products.

In summary, the laser engraver significantly improved my workflow by offering versatility, precision, and ease of use, making it an invaluable tool in my woodworking projects.

Soo Fischer –

“Exceptional laser engraver! Precision and detail in every cut, intuitive software, swift performance, and solid build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Ana Lopez –

“Outstanding laser engraver! Impressive precision and detail in every cut. User-friendly software and smooth operation boost efficiency. Sturdy build, reliable performance—highly recommend! ⭐⭐⭐⭐⭐”

Young Johnson –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and solid build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”

Jin Kim –

“Exceptional laser engraver! Precise cuts, intuitive software, swift performance, and solid build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Javier Vu (verified owner) –

“I recently used this laser engraving machine for my friend’s new business logo on both metal and acrylic. The precision was amazing—each detail came out so sharp! It made the whole process much easier than I expected.”

David Wang –

Five stars for this laser engraver! The engraving quality and precision are exceptional. The operation and software are user-friendly. Fast speeds boost productivity. Sturdy build, highly reliable.