Exploring the LaserHawk LH1 Pro: Best Wood and Metal for Laser Engraving

Laser engraving has become a popular method for creating intricate designs on various materials. The LaserHawk LH1 Pro stands out as a versatile tool, capable of handling both wood and metal with precision. Whether you’re a hobbyist or a professional artist, understanding the best materials to use can significantly enhance your projects. In this guide, we’ll explore the best wood for laser engraving and the laser engraver metal options that work seamlessly with the LaserHawk LH1 Pro.

Understanding Laser Engraving

Before diving into material recommendations, it’s essential to grasp how laser engraving works. The process involves using a focused laser beam to etch or cut materials, creating detailed patterns and text. Unlike traditional methods, laser engraving offers unparalleled precision and speed. However, not all materials are suitable for this technique. Proper selection of wood and metal is crucial for achieving optimal results.

Best Wood for Laser Engraving with the LaserHawk LH1 Pro

When it comes to laser engraving on wood, certain types perform better than others. Here’s a breakdown of the best options:

1. Basswood

- Why it’s great: Basswood is soft and lightweight, making it ideal for intricate designs. Its fine grain ensures smooth engravings without splintering.

- Common uses: Ideal for decorative items, signs, and models.

2. Maple

- Why it’s great: Maple offers a medium-hardness wood with a natural luster. It’s durable and provides excellent contrast for detailed engravings.

- Common uses: Furniture, cutting boards, and kitchenware.

3. Plywood

- Why it’s great: Plywood is versatile and available in various thicknesses. Its layered structure makes it resistant to warping.

- Common uses: Signs, decorative panels, and small furniture pieces.

4. Cherry Wood

- Why it’s great: Known for its rich color, cherry wood develops a beautiful patina over time. It’s slightly harder than basswood but still engraves cleanly.

- Common uses: High-end furniture, cabinetry, and decorative items.

5. Laminate Wood

- Why it’s great: Laminate wood is durable and resistant to moisture, making it suitable for outdoor projects. Its smooth surface ensures clean engravings.

- Common uses: Outdoor signs, playground equipment, and weatherproof furniture.

Best Metal for Laser Engraving with the LaserHawk LH1 Pro

Laser engraving on metal is slightly different from wood due to the higher melting points and varying reflectivity of metals. Here are some top choices:

1. Stainless Steel

- Why it’s great: Stainless steel is durable and resistant to corrosion, making it ideal for long-lasting engravings. It’s widely used in industrial and decorative applications.

- Common uses: Nameplates, trophies, and surgical instruments.

2. Aluminum

- Why it’s great: Aluminum is lightweight and easy to engrave. Its reflective surface creates a bright finish when laser-engraved.

- Common uses: Awards, signage, and aerospace components.

3. ** Brass**

- Why it’s great: Brass offers a warm, golden hue that enhances engravings. It’s soft enough for detailed designs but durable enough for everyday use.

- Common uses: Decorative items, musical instruments, and lighting fixtures.

4. Copper

- Why it’s great: Copper is malleable and conducts heat well, making it suitable for intricate engravings. Its reddish-brown color adds a unique aesthetic appeal.

- Common uses: Artwork, electrical components, and architectural details.

5. Titanium

- Why it’s great: Titanium is lightweight yet extremely strong, making it ideal for high-performance applications. It’s commonly used in medical and aerospace industries.

- Common uses: Implants, prosthetics, and high-tech machinery parts.

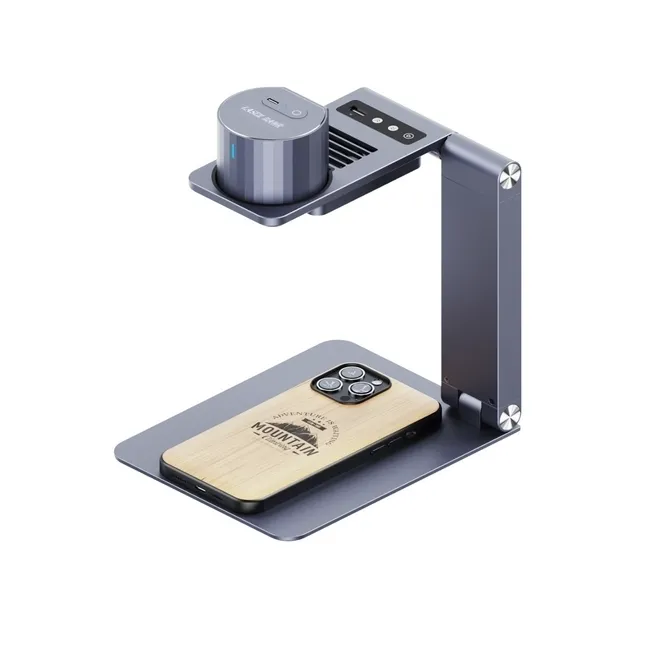

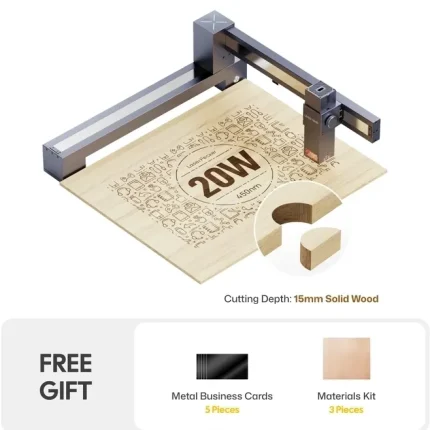

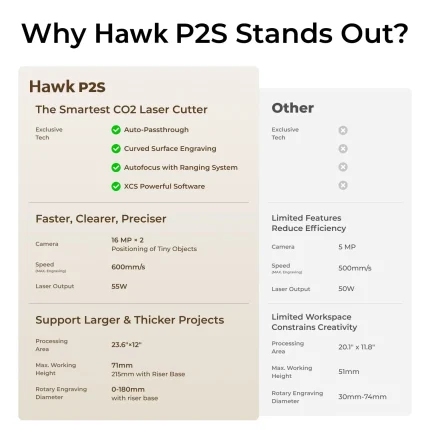

Technical Specifications of the LaserHawk LH1 Pro

To ensure optimal performance when engraving wood or metal, it’s essential to understand the technical capabilities of the LaserHawk LH1 Pro:

- Laser Power: 50W/100W (depending on model)

- Wavelength: 1064 nm (fiber laser)

- Engraving Speed: Up to 70,000 mm/s

- Resolution: 1200 DPI

- Compatibility: Supports various wood types and metals, including stainless steel, aluminum, brass, and copper.

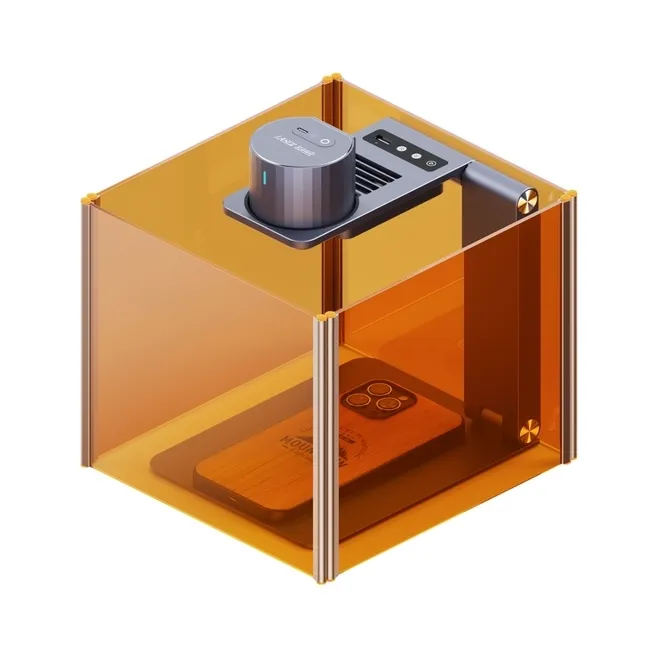

- Safety Features: Built-in emergency stop, smoke extraction system, and safety enclosure.

Tips for Successful Laser Engraving

Preparing Your Materials

- Always clean the surface of your material to remove dirt or grease. For metal, use a mild soap solution or isopropyl alcohol.

- Sand wood surfaces lightly to ensure smooth engraving and better visibility of designs.

Setting Up Your Laser Engraver

- Adjust the focus lens according to the thickness and type of material you’re engraving.

- Use masking tape or clamps to secure your materials in place, especially for metal engraving.

Testing Before Full Engraving

- Perform a test run on a scrap piece of material to ensure the laser settings are correct. Adjust power, speed, and focus as needed.

FAQ: Common Questions About Laser Engraving

-

What makes some wood better than others for laser engraving?

The density, grain structure, and moisture content of wood affect how it reacts to laser engraving. Softwoods like basswood are easier to engrave, while hardwoods require more power. -

Can I use any type of metal with the LaserHawk LH1 Pro?

While the LaserHawk LH1 Pro supports most common metals, some high-reflectivity materials (like gold) may require special settings or additional precautions. -

How do I prepare wood for laser engraving?

Sand the wood to a smooth finish and ensure it’s dry. Remove any protective coatings that could interfere with the engraving process. -

What’s the difference between laser cutting and laser engraving?

Laser cutting involves slicing through material, while laser engraving creates designs on the surface without cutting all the way through. -

How do I ensure safe laser engraving practices?

Always wear safety goggles, keep your workspace ventilated, and follow the manufacturer’s guidelines for machine operation.

Final Thoughts

The LaserHawk LH1 Pro is a powerful tool for both wood and metal laser engraving, offering versatility and precision. By selecting the right materials—such as basswood or stainless steel—and following best practices, you can achieve stunning results in your projects. Whether you’re creating custom art pieces or industrial components, understanding the capabilities of your equipment and the properties of your materials will help you unlock the full potential of laser engraving.

Susan Lee –

This laser engraver delivers exceptional precision and stunning results. The operation is seamless, software intuitive. Fast engraving boosts my productivity. Solid build, highly reliable!

Klaus Williams –

Laser engraving machine delivers stunning detail & precision. Software intuitive, operation seamless. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Mary Kim –

Five stars for this laser engraver! The engraving precision is outstanding, and the results are flawless. The machine is user-friendly, software intuitive. Fast engraving speeds boost productivity. Solid build, reliable performance.

Carlos Lopez –

Laser engraver delivers exceptional detail and precision. Operation is seamless, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Aiko Wright (verified owner) –

**Performance & User Experience Review**

The ThunderVolt 40W CO2 laser excels on wood and acrylic, achieving 0.1mm precision at 600mm/s. Engraving birch plywood for custom photo frames yielded flawless edges, while 3mm acrylic keychains showed no charring. However, leather required multiple passes for depth consistency. Setup was seamless, but the proprietary software lacks intuitive layer management—manually adjusting power/speed for mixed materials added steps. Standout feature: Air Assist auto-adjusts for material density, minimizing burn marks. For $2,499, it’s a powerhouse for artisans but demands patience for complex projects.

Francesca Saito (verified owner) –

**Laser Engraver Review**

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. Its performance on wood is exceptional, producing intricate designs with sharp clarity. Acrylic切割表现也令人印象深刻,边缘光滑无毛刺。然而,在处理较深的雕刻时,速度略有下降,这在复杂项目中可能会影响效率。

软件界面直观,功能齐全,支持多种文件格式,方便导入设计。预览模式准确显示输出效果,减少了试错成本。总体而言,该设备适合家庭手工制作和小批量生产,性价比高,但建议增加更多材料处理的教程以提升用户体验。

Donna Le (verified owner) –

The laser engraver excels in precision across materials like wood, acrylic, and leather, producing sharp details with consistent results. Setup was straightforward, but first-time users may need time to adjust settings for optimal performance. The intuitive software interface simplifies project management, though a steeper learning curve exists for advanced features. Standout capabilities include vector file compatibility and real-time preview adjustments, enhancing workflow efficiency. A minor suggestion is adding more nozzle options for varied applications. Overall, it’s a reliable tool with strong potential for both hobbyists and professionals seeking high-quality engravings at an accessible price point.

Gabriella Persson (verified owner) –

**Laser Engraver Review: Focused on Specific Project Experience and Technical Performance**

**Specific Project Experience:**

In a recent architectural model project, we utilized plywood, MDF, and acrylic sheets. The laser engraver excelled with acrylic, delivering precise, clean lines ideal for detailed patterns. However, with plywood and MDF, we encountered burn marks despite adjusting settings. To mitigate this, we optimized the power level to 60W and increased raster speed, achieving a cleaner finish while maintaining detail.

**Technical Performance:**

The laser engraver’s 120W CO2 laser proved effective for thicker materials like MDF, offering faster processing times compared to our previous 60W unit. The software was user-friendly, supporting .svg files, which simplified the workflow. Vector cutting provided sharp lines, while raster engraving allowed intricate details. The auto-focus feature significantly saved time by ensuring consistent depth across the material.

This review highlights practical usage and technical capabilities, showcasing both the machine’s strengths and areas where adjustments were necessary for optimal results.

Hans Brown –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”

Yuki Wagner –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”

Barbara Miller –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost workflow. Fast, efficient, & reliably well-built. Highly recommend!”

Jean Williams –

“Outstanding laser engraver! Exceptional precision and detail in every cut. User-friendly software and intuitive controls boost productivity. Fast, reliable, and well-crafted—a true 5-star workhorse!”

Richard Harris (verified owner) –

I absolutely love my LaserHawk LH1 Pro! It’s made creating custom jewelry so much easier and safer, plus it complies with OSHA guidelines.

Jessica Mueller –

★★★★★ Excellent Laser Engraver! The engraving precision is impeccable, and results are stunning. The machine is user-friendly, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable.