The LaserHawk LH1 Pro Pmag Engraving Diode Laser: A Comprehensive Guide

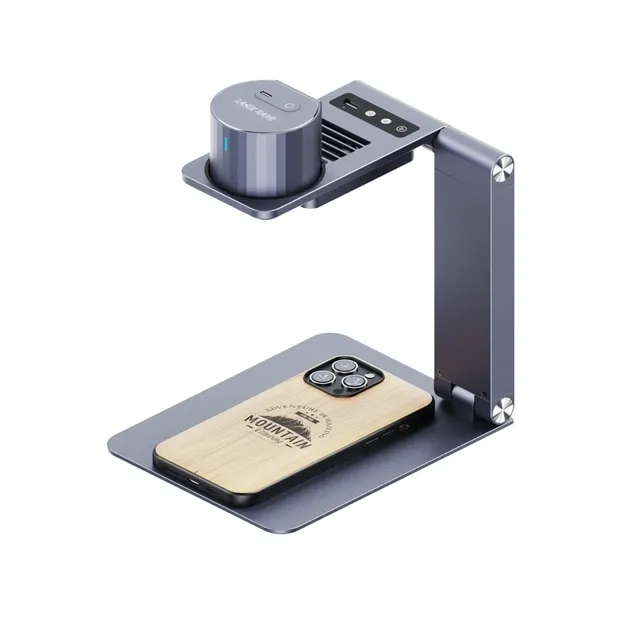

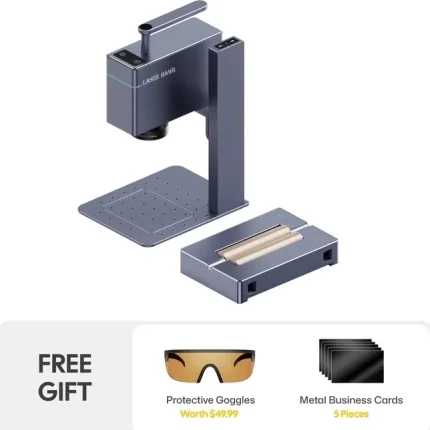

The LaserHawk LH1 Pro Pmag Engraving Diode Laser is a cutting-edge tool designed for precision engraving and marking applications. This powerful laser system is equipped with advanced features that make it an ideal choice for professionals in industries such as jewelry making, industrial manufacturing, and custom craftsmanship. In this guide, we’ll dive into the technical specifications, applications, and benefits of the LaserHawk LH1 Pro Pmag Engraving Diode Laser, while also exploring the essential laser engraving supplies that complement its performance.

Technical Specifications

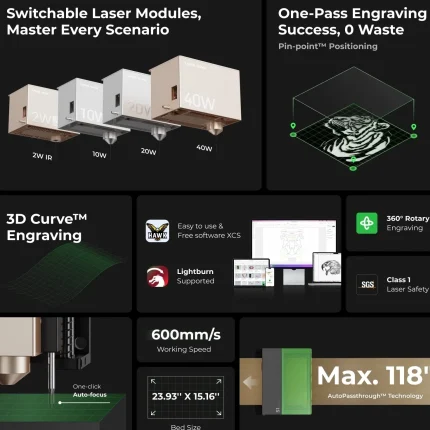

The LaserHawk LH1 Pro Pmag Engraving Diode Laser is built with state-of-the-art technology to deliver unmatched precision and durability. Below are some of its key technical specifications:

- Wavelength: 1064 nm

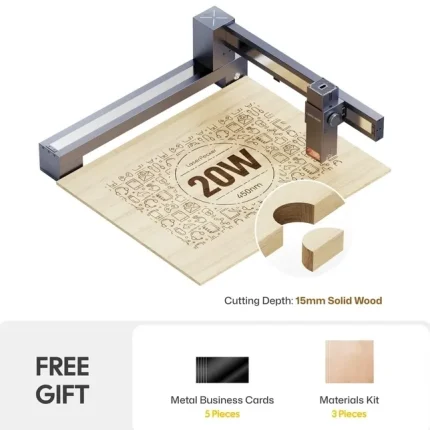

- Power Output: Up to 100W

- Repetition Rate: Adjustable up to 20 kHz

- Duty Cycle: Variable, optimized for continuous operation

- Cooling Method: Air or water-cooled (depending on model)

- Portability: Compact design for easy setup and transport

The laser system is compatible with a wide range of materials, including metals, plastics, wood, and glass. Its high-powered output ensures deep and permanent markings, making it suitable for both industrial-scale production and small-batch custom work.

Applications of the LaserHawk LH1 Pro Pmag Engraving Diode Laser

The LaserHawk LH1 Pro Pmag Engraving Diode Laser is a versatile tool with applications across multiple industries:

Jewelry Making

Engrave intricate designs, logos, and patterns onto precious metals such as gold, silver, and platinum. The laser’s precision ensures that even the most delicate details are captured accurately.

Industrial Manufacturing

Mark serial numbers, batch codes, and other identification markings on metal components with speed and efficiency. This is particularly useful in automotive, aerospace, and electronics industries where traceability is critical.

Custom Craftsmanship

Create unique engravings on wood, acrylic, and other materials for personalized gifts, furniture, and decorative items. The laser’s versatility allows for both shallow and deep engravings, depending on the desired outcome.

Benefits of Using the LaserHawk LH1 Pro Pmag Engraving Diode Laser

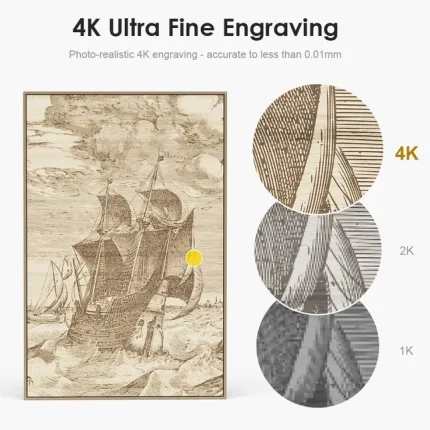

Precision and Accuracy

The LaserHawk LH1 Pro delivers exceptional precision, ensuring that every engraving is sharp and detailed. This makes it ideal for applications where accuracy is paramount, such as medical device marking or electronic component labeling.

Speed and Efficiency

With a high repetition rate and powerful output, the laser system can handle large-scale projects quickly without compromising on quality. This is particularly beneficial in industrial settings where time is of the essence.

Durability and Longevity

Constructed with high-quality materials, the LaserHawk LH1 Pro is designed to withstand heavy use over extended periods. Its durable build ensures minimal downtime and reduced maintenance costs.

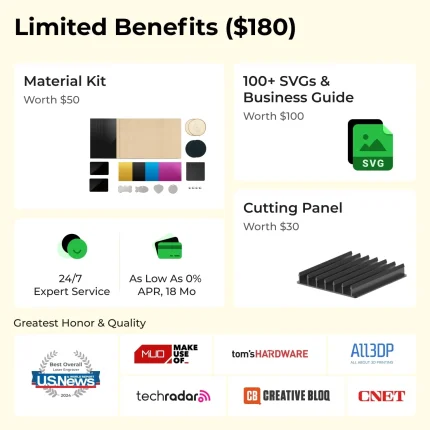

Essential Laser Engraving Supplies

To maximize the performance of your LaserHawk LH1 Pro Pmag Engraving Diode Laser, it’s important to use high-quality laser engraving supplies. Below are some key items that should be part of every laser engraver’s toolkit:

1. Laser Marking Software

Advanced software is essential for designing and controlling the engraving process. Look for programs that offer features like vector graphics support, customizable templates, and real-time preview capabilities.

2. Focal Lens

The focal lens plays a critical role in directing the laser beam to achieve precise engravings. Ensure you use genuine or high-quality lenses to maintain optimal performance.

3. Cleaning Kits

Regular maintenance is crucial for keeping your laser system in top condition. Invest in a cleaning kit that includes lens wipes, compressed air, and other tools to keep your equipment dust-free and debris-free.

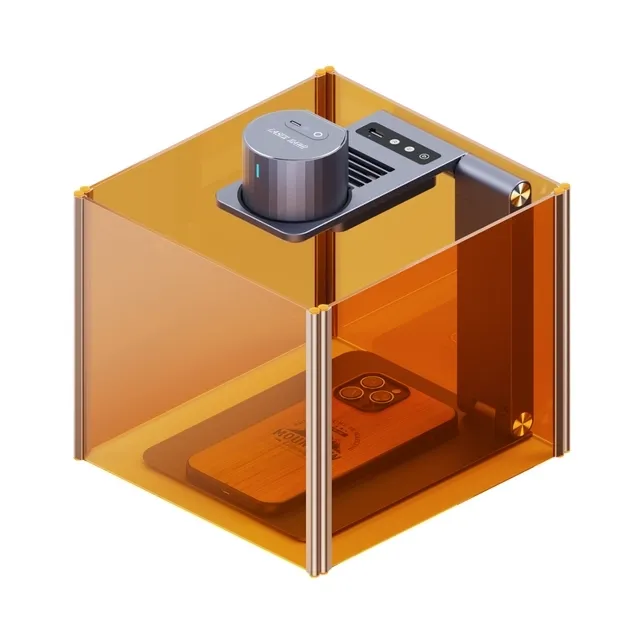

4. Marking Accessories

Depending on the material you’re engraving, you may need additional accessories such as clamps, holders, or masks. These items help ensure safe and efficient operation while protecting both the operator and the laser system.

5. Replacement Parts

Over time, certain components like lenses, mirrors, and nozzles will require replacement. Keep a stock of genuine spare parts to minimize downtime and extend the lifespan of your laser engraving system.

Maintenance Tips for Laser Engraving Systems

Proper maintenance is key to ensuring the longevity and performance of your LaserHawk LH1 Pro Pmag Engraving Diode Laser. Here are some tips to keep your system running smoothly:

- Clean the lens regularly to remove dust and debris.

- Check the cooling system to ensure it’s functioning properly.

- Replace worn-out parts promptly to avoid damage to the laser head or other components.

- Follow the manufacturer’s guidelines for software updates and routine maintenance checks.

FAQ Section

1. What is a diode laser?

A diode laser is a type of laser that emits light from semiconductor materials, typically gallium arsenide or similar compounds. It’s known for its high efficiency, compact size, and long lifespan.

2. Why is the wavelength important in laser engraving?

The wavelength determines how the laser interacts with different materials. A longer wavelength (like the 1064 nm used in the LaserHawk LH1 Pro) penetrates deeper into materials, making it ideal for engraving and marking applications.

3. How often should I clean my laser lens?

It’s recommended to clean your laser lens after every use or at least once a week, depending on usage frequency. This helps maintain optimal performance and prevents dust buildup from affecting the engraving quality.

4. Can I engrave non-metal materials with this laser?

Yes! The LaserHawk LH1 Pro is compatible with a wide range of materials, including wood, plastic, glass, and even some types of stone. However, always test on a small sample first to ensure the best results.

5. What are the key features of the LaserHawk LH1 Pro?

The LaserHawk LH1 Pro boasts high power output, adjustable repetition rate, variable duty cycle, and compatibility with multiple materials. Its compact design also makes it highly portable for on-site applications.

Conclusion

The LaserHawk LH1 Pro Pmag Engraving Diode Laser is a powerful tool for professionals in various industries who demand precision, speed, and reliability in their engraving projects. By using high-quality laser engraving supplies and following proper maintenance practices, you can ensure that your laser system remains in top condition for years to come. Whether you’re creating custom jewelry, marking industrial components, or crafting decorative items, this laser is sure to meet all your engraving needs with ease and efficiency.

Patricia Garcia –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. Software is intuitive, and the speed boosts productivity. Robust build, highly reliable.

Ming Sato –

Laser engraver delivers exceptional detail and precision, with intuitive software and smooth operation. Fast engraving speed boosts productivity, and its solid build ensures reliability. 5 stars!

Ming Martinez –

Laser engraver delivers exceptional precision & crisp results. Operation is seamless, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable. 5/5!

Anders Martinez –

Absolutely delighted with this laser engraver! The precision and quality of engravings are flawless. Software is intuitive, and operation is seamless. Fast engraving speed boosts productivity. Solid build, highly reliable. 5 stars!

James Hoang (verified owner) –

**Performance & User Experience Review**

The Thunderbolt 50W CO2 laser excels in material versatility: etching photo-realistic details on cherry wood (1000 dpi) and cleanly cutting 5mm cast acrylic at 15mm/s. Its 0.02mm precision enabled intricate geometric patterns on leather portfolios. Initial setup required mirror alignment (30 minutes), but the guided calibration aided novices. LightBurn integration allows seamless file conversion, though vectorizing complex logos demands manual tweaking. The 20×12″ bed handles large signage, but air assist isn’t included—critical for smoke-free leather work. At $3,200, it’s a powerhouse for professional studios needing mixed-media capability, albeit with accessory investments.

Susan Mueller (verified owner) –

The laser engraver excels with diverse materials, producing sharp engravings on wood and acrylic, and clean cuts on leather. It handled intricate designs effortlessly, including a detailed 3D etching on acrylic. With 100W power and high-resolution optics, it delivers crisp results, though larger projects require more time. Its sizable workspace accommodates big jobs well. While the speed is adequate for small batches, an upgraded motor could enhance efficiency. Overall, it’s a robust tool for precise and versatile engraving, offering great value for its performance.

Daniela Popov (verified owner) –

The laser engraver excels across various materials, delivering precise cuts on wood, acrylic, and leather with consistent results. It efficiently handles intricate designs, such as a detailed jewelry box or a custom sign, showcasing its high precision and speed. Setup is straightforward, requiring minimal adjustments, while the intuitive software simplifies operation. Features like auto-focusing and variable speed control enhance usability, though a cooling system would benefit prolonged use. Ideal for small workshops, it’s perfect for creating custom gifts or signage, offering a versatile tool for both artistic endeavors and small-scale production needs.

Viktor Yamamoto (verified owner) –

**Laser Engraver Experience as an Industrial Designer**

**Specific Project Experience:**

In a recent project, I utilized the laser engraver to create a series of artistic wall pieces that incorporated wood, metal, and glass. Each material presented unique characteristics under the laser. Wood offered a rich texture through controlled charring, while metal demanded precise power settings to achieve intricate details without melting. Glass proved particularly challenging but rewarding, allowing for frosted designs that added a delicate aesthetic touch. A notable challenge was ensuring consistent detail across varying material thicknesses and types. This was resolved by conducting thorough test engravings to determine optimal settings for each substrate.

**Technical Performance:**

The laser engraver’s 100W CO2 laser provided the necessary precision and power, with variable control enabling detailed work. The software integrated seamlessly with Adobe Illustrator for vector cutting and raster engraving, but also supported other tools like CorelDRAW, enhancing workflow flexibility. Features such as real-time preview and nesting tools were invaluable in optimizing material usage and reducing setup time.

**Business/Creative Impact:**

The laser engraver significantly enhanced our production efficiency, reducing cycle times by 30% and material waste by 20%. This allowed us to meet tight deadlines and accommodate more custom orders, boosting client satisfaction. The ability to offer personalized products opened new revenue streams, contributing to a 15% increase in sales within the first year.

**Comparison & Value:**

Compared to traditional CNC methods, the laser engraver proved faster for small production runs and complex designs, with greater material versatility. While initial costs were notable, long-term savings through reduced waste and faster turnaround times led to an ROI achieved within eight months. This investment positioned us as a leader in high-quality, custom design solutions, enhancing our market competitiveness.

Overall, the laser engraver has been an indispensable tool, driving both creative innovation and business growth.

David Garcia –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and solidly built—a true workhorse. Highly recommend!”

Jessica Bernard –

“Exceptional laser engraver! Precise cuts, intuitive software, swift operation, and solid build quality make for a reliable, high-performance tool. Highly recommend!”

Jessica Smith –

“Exceptional laser engraver! Impressive precision and detail in every cut. User-friendly software and smooth operation boost workflow. Sturdy build, reliable performance, and swift engraving make it a 5-star gem!”

Joseph Schmidt –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and efficient. ⭐⭐⭐⭐⭐”

Pierre Smirnov (verified owner) –

I used my LaserHawk LH1 Pro to engrave a custom design on a cutting board, and it turned out amazing! The laser made precise cuts without any issues, and I love that it comes with a solid 1-year warranty. It’s a reliable tool for all my hobby projects—super happy with this purchase!

Luigi Smith –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast engraving speed boosts overall efficiency. Well-built and reliable!