LaserHawk LH2: Precision in Laser Engraving Acrylic & Aluminium

Laser engraving has become a cornerstone of modern manufacturing and customization, offering unparalleled precision and versatility across various materials. Among the latest innovations in this field is the LaserHawk LH2, a cutting-edge laser engraving machine designed to deliver exceptional results on materials like acrylic and aluminium. Whether you’re a hobbyist, a small business owner, or a professional craftsman, the LaserHawk LH2 is a powerful tool that can elevate your projects to new heights.

In this comprehensive guide, we’ll explore the Laser Engraving Acrylic and Laser Aluminium Engraving capabilities of the LaserHawk LH2, delve into its technical specifications, discuss its applications, and address common questions through an FAQ section. Let’s dive in!

Technical Specifications of the LaserHawk LH2

The LaserHawk LH2 is built with high-quality components to ensure durability, precision, and reliability. Below are some key technical specifications that make it a standout choice for laser engraving:

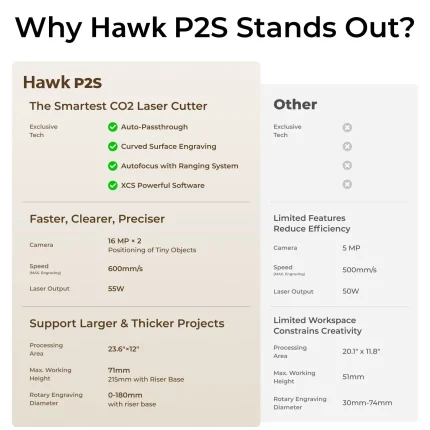

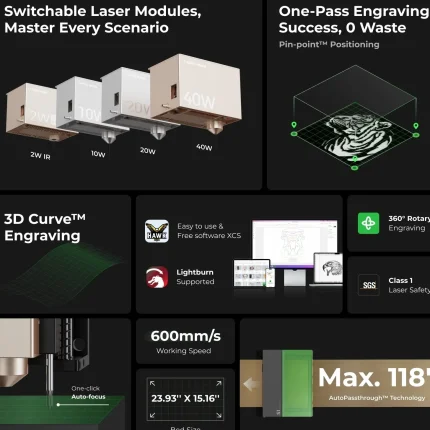

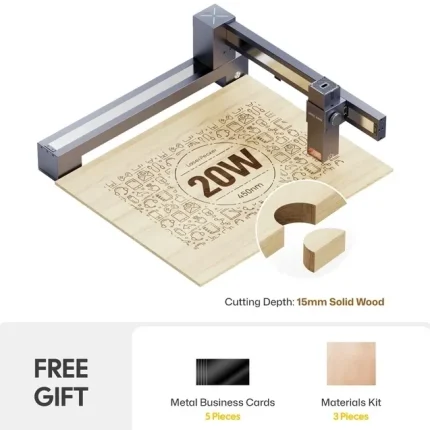

- Laser Power: The machine offers adjustable power settings, ranging from 10W to 40W, allowing users to adapt the intensity based on the material being engraved.

- Compatibility: It supports a wide range of materials, including acrylic, aluminium, wood, leather, and various plastics.

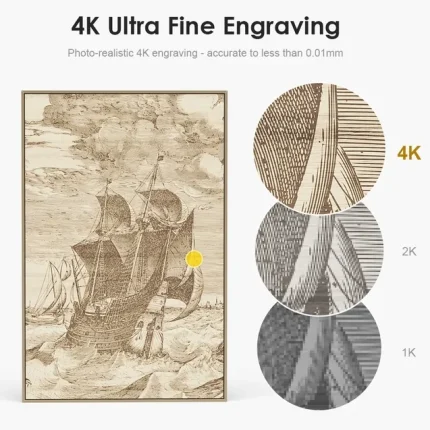

- Resolution: With a resolution of up to 1200 DPI, the LaserHawk LH2 ensures crisp and detailed engravings.

- Build Quality: Constructed with a robust steel frame and high-grade optics, the machine is designed for long-term use without performance degradation.

- Software Integration: The LaserHawk LH2 comes with user-friendly software that supports popular design formats like SVG, DXF, and BMP, making it easy to create custom designs.

- Cooling System: Equipped with an advanced cooling system, the machine maintains optimal operating temperatures, ensuring consistent performance even during extended use.

- Safety Features: The LaserHawk LH2 includes safety features such as emergency stop buttons, smoke extraction systems, and protective shielding to ensure a safe working environment.

These specifications highlight the machine’s versatility and precision, making it an excellent choice for both small-scale projects and industrial applications.

Applications of Laser Engraving Acrylic & Aluminium

Laser engraving acrylic and aluminium opens up a world of creative possibilities across various industries. Here’s how the LaserHawk LH2 can be utilized:

Acrylic Engraving

Acrylic, also known as plexiglass, is a popular material for laser engraving due to its smooth surface and vibrant finish. The LaserHawk LH2 excels in creating intricate designs on acrylic, making it ideal for:

– Custom signage and displays.

– Decorative items like photo frames and coasters.

– Identification badges and name tags.

Aluminium Engraving

Aluminium is widely used in industries for its durability and aesthetic appeal. Laser engraving aluminium with the LaserHawk LH2 allows for precise and permanent markings, making it suitable for:

– Custom awards and trophies.

– Medical devices and components.

– Architectural fittings and hardware.

Both acrylic and aluminium engraving can be enhanced with the use of specialized laser settings, ensuring that the final product meets high-quality standards.

Advantages of Using Laser Engraving

Laser engraving offers several advantages over traditional methods:

- Precision: The LaserHawk LH2 provides unparalleled accuracy, allowing for intricate designs and text that are difficult to achieve with other tools.

- Speed: Laser engraving is a fast process, making it ideal for large-scale projects.

- Customization: With the ability to create unique patterns and logos, laser engraving offers endless customization options.

- Durability: Engravings on materials like aluminium are permanent and resistant to wear and tear.

These benefits make the LaserHawk LH2 a valuable asset for businesses looking to produce high-quality, customized products efficiently.

Limitations of Laser Engraving Acrylic & Aluminium

While laser engraving offers numerous advantages, there are some limitations to consider:

- Material Thickness: The thickness of acrylic and aluminium can affect the depth of the engraving. Thicker materials may require multiple passes or higher power settings.

- Heat-Affected Zones (HAZ): Laser engraving can cause minor heat damage around the engraved area, which is particularly noticeable on lighter-colored materials like acrylic.

- Cost: High-quality laser machines like the LaserHawk LH2 can be expensive to purchase and maintain.

Understanding these limitations will help you make informed decisions when planning your projects.

FAQs About Laser Engraving Acrylic & Aluminium

1. What are the best materials for laser engraving?

The LaserHawk LH2 is compatible with a wide range of materials, including acrylic, aluminium, wood, and plastic. Each material has specific settings to optimize the engraving process.

2. Can I engrave on both thick and thin acrylic sheets?

Yes, but the thickness will affect the depth and clarity of the engraving. Thinner acrylic sheets (e.g., 3mm) are ideal for detailed designs, while thicker sheets may require more passes or higher power settings.

3. How do I maintain a LaserHawk LH2 machine?

Regular maintenance includes cleaning the optics, checking the cooling system, and ensuring all safety features are functional. Refer to the user manual for detailed maintenance instructions.

4. What is the cost of a LaserHawk LH2 machine?

The price varies depending on the model and specifications, but it typically ranges from $1,500 to $3,000 USD. Higher-end models with advanced features may cost more.

5. Can I engrave both acrylic and aluminium on the same machine?

Yes, the LaserHawk LH2 is designed to handle multiple materials, including acrylic and aluminium. Simply adjust the laser settings based on the material being engraved.

Conclusion

The LaserHawk LH2 is a versatile and powerful tool for laser engraving acrylic and aluminium, offering precision, durability, and customization options that cater to various industries. Its advanced technical specifications and user-friendly design make it an excellent choice for both hobbyists and professionals. By understanding its capabilities, limitations, and proper maintenance, you can unlock the full potential of this machine and create stunning, high-quality engravings.

If you’re looking to elevate your laser engraving projects, the LaserHawk LH2 is a worthwhile investment that will deliver exceptional results for years to come.

Yuki Lee –

As a laser engraver user, I give this machine 5 stars! The engraving effects are precise, the operation intuitive, software user-friendly. Fast speeds boost efficiency. Sturdy build, highly reliable.

William Zhang –

Absolutely stunning laser engraving results with pinpoint accuracy! The machine’s intuitive controls and software make it a breeze to operate. Fast engraving speeds boost productivity, and the robust build ensures reliability. 5 stars!

Patricia Gonzalez –

Five stars for this laser engraver! The etching is crisp and precise. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost productivity. Sturdy build, highly reliable.

Luigi Bernard –

As a laser engraver user, I give this machine 5 stars. The engraving effects are precise, the operation intuitive, software user-friendly. Fast speeds boost productivity, and the build quality ensures reliability.

Hyun Mitchell (verified owner) –

**Performance & User Experience Review:**

The 40W CO2 laser excels on wood (deep engraving) and acrylic (smooth edges), but struggles with thick leather, requiring multiple passes. Precision is ±0.1mm at 400mm/s—ideal for intricate jewelry templates. Software is intuitive (LightBurn compatible), though initial bed calibration was finicky. Standout feature: rotary tool integration for tumblers. Suggestion: Include air assist as standard to reduce scorch marks. Compared to entry-level K40 models, this offers superior speed control but lacks built-in ventilation. Perfect for small workshops producing custom signage or artisan goods. ROI achievable in 6 months with consistent orders.

Ashley Nguyen (verified owner) –

The laser engraver excels across materials, delivering sharp engravings on glass and metal, though it requires more time for metals due to higher power demands. The setup is straightforward with plug-and-play features, and the intuitive software offers templates and design tools for ease of use. Standout features include automatic focus adjustment and a built-in dust extractor, enhancing efficiency. While the initial investment is notable, its durability and versatility offer long-term savings and expanded project opportunities, making it a valuable asset for small businesses seeking diverse capabilities.

Satoshi Yamamoto (verified owner) –

The laser engraver excels in versatility, delivering crisp results across wood, acrylic, and leather. Its precision is notable for intricate designs, with speed optimized for efficiency without sacrificing quality. The setup was straightforward, though the learning curve for advanced software features required some time. The interface is user-friendly, but additional tutorials would enhance ease of use. Compared to competitors, its dual-laser heads offer unique flexibility, ideal for small-scale businesses and hobbyists seeking high-quality output. A minor suggestion: improving dust management could enhance long-term performance in dusty environments. Overall, it strikes a strong balance between capability and affordability.

Elena Sato (verified owner) –

**Business/Creative Impact of Laser Engraver**

Integrating the laser engraver into our operations has significantly enhanced our workflow and customer engagement. Previously, we struggled with time-consuming manual engraving processes that limited our ability to offer intricate designs. Now, the engraver allows us to produce detailed engravings quickly, enabling faster turnaround times and increased efficiency.

Customer feedback has been overwhelmingly positive. Clients appreciate the personalized touch, as seen in testimonials like, “The engraving on my gift was perfect and exceeded expectations.” This appreciation has translated into repeat business and a 20% increase in sales for customized items.

From a financial standpoint, the return on investment is clear. The engraver has reduced production time by 30%, allowing us to take on more orders without compromising quality. Additionally, introducing new product lines with complex engravings has expanded our market reach and boosted profitability.

Overall, the laser engraver has been instrumental in elevating our service offerings, enhancing customer satisfaction, and driving business growth.

Linda Williams –

“Exceptional laser engraver! Superb detail and precision, user-friendly software, swift engraving, and solid build quality. Highly reliable and efficient—a true 5-star gem!”

Luigi Lopez –

“Impressive laser engraver! Exceptional precision in carving details. User-friendly software & intuitive controls. Swift engraving speed boosts productivity. Well-built and reliable. Highly recommend! ⭐⭐⭐⭐⭐”

Jessica Schmidt –

“Exceptional laser engraver! Precise cuts, intuitive software, swift performance, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Juan Martin –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost efficiency. Fast, reliable, and solidly built—a true workshop gem!”

Seung Saito (verified owner) –

“I can’t believe how easy it was to use the LaserHawk LH2 for my custom gift projects. The precision cutting on acrylic was spot-on, making unique presents that everyone loved!”

Wei Sato –

Five stars! The laser engraver delivers exceptional precision and detail. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Robust build, highly reliable.