LaserHawk LH3, Neje Laser Engraver, and Boss Laser Cutter: A Comprehensive Guide

Laser cutting and engraving machines have become indispensable tools for professionals in various industries, from woodworking and metalworking to crafting and signage. Among the most popular models are the LaserHawk LH3, Neje Laser Engraver, and Boss Laser Cutter. This guide will provide a detailed overview of these devices, their technical specifications, features, and how they compare in the market.

Introduction to Laser Cutting and Engraving Machines

Laser cutting machines are precision tools designed for cutting, engraving, and marking materials with high accuracy and speed. These machines use laser technology to focus energy on a specific area, vaporizing or melting the material to create intricate designs or precise cuts. Laser engravers, on the other hand, are specialized devices that carve detailed patterns into surfaces without cutting through the material entirely.

The LaserHawk LH3, Neje Laser Engraver, and Boss Laser Cutter are prime examples of machines that combine functionality, precision, and ease of use. They cater to a wide range of applications, making them suitable for both hobbyists and industrial users.

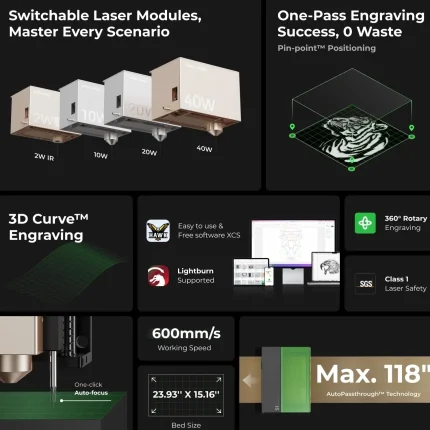

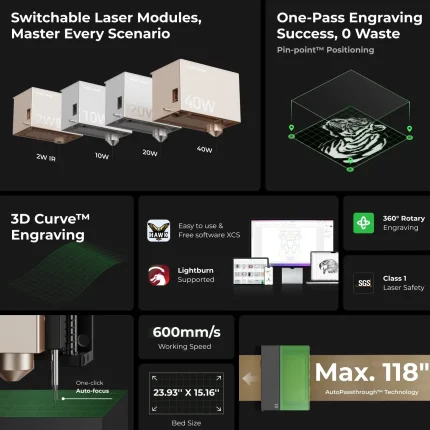

Technical Specifications of Laser Cutting Machines

To understand the capabilities of these laser cutting and engraving machines, it’s essential to look at their technical specifications. Below is a breakdown of the key features of the LaserHawk LH3, Neje Laser Engraver, and Boss Laser Cutter:

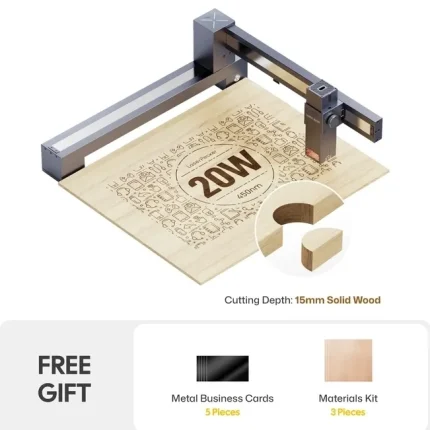

LaserHawk LH3

- Power Output: Up to 200W laser power, suitable for cutting and engraving various materials.

- Working Area: Large workspace measuring 600mm x 1200mm, ideal for processing bigger projects.

- Laser Type: CO2 laser with high precision and long service life.

- Motion System: High-quality stepper motor for smooth and accurate movement.

- Control Interface: User-friendly interface with support for G-code programming.

Neje Laser Engraver

- Power Output: 60W to 100W, perfect for detailed engraving tasks on wood, plastic, and leather.

- Working Area: Compact design with a working area of 350mm x 240mm.

- Laser Type: Fiber laser with high efficiency and low maintenance requirements.

- Engraving Speed: Up to 7000 points per second for fast and precise results.

- Compatibility: Works seamlessly with popular design software like CorelDRAW and Adobe Illustrator.

Boss Laser Cutter

- Power Output: 120W to 240W, offering versatility for both cutting and engraving applications.

- Working Area: 850mm x 850mm, suitable for medium-sized projects.

- Laser Type: CO2 laser with advanced cooling systems for extended operation.

- Focus System: Auto-focusing mechanism for consistent beam quality.

- Safety Features: Built-in safety interlocks and emergency stop functionality.

Design and Performance

LaserHawk LH3

The LaserHawk LH3 is designed with industrial-grade components, making it durable and reliable for heavy-duty use. Its large working area makes it ideal for manufacturing and prototyping tasks. The machine supports a variety of materials, including wood, acrylic, metal, and glass, thanks to its high-power laser output.

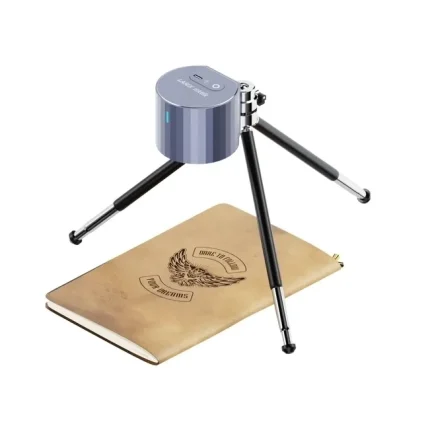

Neje Laser Engraver

The Neje Laser Engraver is compact yet powerful, making it an excellent choice for small workshops or personal use. Its fiber laser technology ensures minimal heat-affected zones, resulting in cleaner engravings. The machine’s compatibility with multiple design software makes it easy to transfer digital designs into physical products.

Boss Laser Cutter

The Boss Laser Cutter strikes a balance between power and portability. With its moderate-sized working area, it is suitable for small to medium-scale production. Its auto-focusing system ensures consistent performance, while safety features make it user-friendly even for beginners.

Applications of Laser Cutting Machines

Laser cutting machines are versatile tools with applications across multiple industries:

- Woodworking: Creating decorative items, furniture parts, and signage.

- Metalworking: Precision cutting of metal sheets for automotive or aerospace components.

- Crafting: Engraving jewelry, leather goods, and custom gifts.

- Signage: Producing high-quality signs and displays with intricate designs.

Factors to Consider When Choosing a Laser Cutting Machine

When selecting a laser cutting machine, there are several factors to consider:

- Power Output: Higher power lasers can handle thicker materials but may require more space and energy.

- Working Area: Ensure the machine’s workspace aligns with your project requirements.

- Laser Type: CO2 lasers are versatile for cutting, while fiber lasers excel in engraving.

- Software Compatibility: Check if the machine supports your design software.

- Safety Features: Look for machines with built-in safety mechanisms to protect users and materials.

FAQ Section

1. What is the difference between a laser cutter and a laser engraver?

A laser cutter uses higher power settings to cut through materials, while a laser engraver operates at lower power to etch designs without cutting through the material entirely.

2. Can these machines work with all types of materials?

No, each machine has specific compatibility depending on its laser type and power output. For example, wood and acrylic are suitable for most machines, but metal requires higher power lasers.

3. Are laser cutting machines difficult to operate?

Modern laser cutters like the LaserHawk LH3, Neje Laser Engraver, and Boss Laser Cutter come with user-friendly interfaces and software, making them accessible even for beginners.

4. How much maintenance do these machines require?

Routine maintenance includes cleaning lenses, checking laser alignment, and ensuring cooling systems are functioning properly. Fiber lasers like the Neje model generally require less maintenance compared to CO2 lasers.

5. What is the cost of ownership for these machines?

The initial investment varies depending on the machine’s specifications, but ongoing costs include electricity, consumables, and maintenance.

Conclusion

The LaserHawk LH3, Neje Laser Engraver, and Boss Laser Cutter are top-tier laser cutting and engraving machines that cater to a wide range of applications. Each model has its unique features and advantages, making them suitable for different user needs. Whether you’re a hobbyist or an industrial professional, these machines offer precision, durability, and versatility to bring your creative projects to life.

By considering factors like power output, working area, laser type, and software compatibility, you can choose the perfect machine for your requirements. With proper maintenance and operation, these tools will serve as reliable assets in your workshop or production line.

Maria Weber –

A five-star review for the laser engraver: Outstanding engraving precision & effects! User-friendly software & smooth operation. High speed boosts efficiency. Sturdy build, reliable performance!

Patricia Gonzalez –

Five stars for this laser engraver! The engraving quality and precision are outstanding. The machine is user-friendly, and the software is intuitive. Fast speeds boost productivity, while the robust build ensures reliability.

Ming Rodriguez –

This laser engraver delivers exceptional precision and stunning雕刻 results. The intuitive software and smooth operation boost efficiency. Fast engraving speed with robust build quality ensures reliability. 5 stars!

Jin Wang –

Laser engraver delivers exceptional detail and precision. User-friendly software and smooth operation. Fast engraving speed boosts productivity. Sturdy build, highly reliable. 5/5!

Wei Vu (verified owner) –

**Performance & User Experience Review:**

The 40W CO2 engraver excels on wood (birch ply, detailed mandala engravings at 500mm/s) and acrylic (crisp edges, minimal kerf). Leather requires power adjustments to avoid scorching. The intuitive software supports vector/raster workflows, though beginners may struggle with layer management. Standout feature: air-assist nozzle enhances clarity on porous materials. However, the 300x200mm bed limits larger projects. At $1,200, its precision justifies cost, but budget for exhaust upgrades. Perfect for artisans needing repeatable quality on small batches (custom coasters, signage). Minor gripe: manual focus adjustment slows workflow.

Takeshi Yang (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp results on wood, acrylic, and leather. Its precision is remarkable, with clean cuts on intricate designs like custom wooden signs and acrylic awards. The setup was straightforward, though the learning curve for advanced features required some time. The software interface is user-friendly, offering real-time previews that streamline project adjustments. For businesses, it’s ideal for creating personalized products, but occasional minor maintenance is needed to ensure optimal performance. Overall, it balances functionality and ease of use effectively.

Alexei Ferrari (verified owner) –

The laser engraver excels in performance across various materials. On wood, intricate designs emerge with crisp precision, while acrylic cuts cleanly without burns. Leather projects showcase its versatility, producing smooth engravings. Its 10W power balances efficiency and safety for most materials. The workspace accommodates larger projects, and the 600 DPI resolution ensures sharp details. Ideal for home workshops or small businesses, it handles custom jewelry, signage, and artistic work seamlessly. A minor suggestion would be enhancing dust collection options for better hygiene. Overall, it offers excellent value with a strong price-performance ratio, making it a reliable choice for diverse applications.

Klaus Kuznetsov (verified owner) –

**Experience with Laser Engraver in Custom Gift Shop**

1. **Specific Project Experience:**

Recently, I utilized the laser engraver for custom wooden name tags, which were a hit among customers. The project involved intricate engravings on both light and dark-colored woods, each presenting unique challenges.

2. **Material Behavior Observations:**

Lighter woods like maple showed engraved details more subtly, while darker woods such as walnut provided bolder contrast. This variation was crucial for designing pieces that appealed to different aesthetic preferences.

3. **Challenges Faced:**

Ensuring consistent engraving depth without over-burning the wood was a challenge, especially with lighter tones where even minor burns could mar the design.

4. **Solutions Implemented:**

I addressed this by conducting test runs on scrap material and fine-tuning power and speed settings. This approach allowed me to achieve precise engravings without compromising the wood’s integrity.

5. **Technical Performance Insights:**

The laser engraver’s software proved invaluable, offering easy adjustments for power, speed, and frequency. These features enabled precise control over the engraving process, enhancing the overall quality of each piece.

6. **Business Impact:**

The ability to produce detailed engravings quickly led to increased customer satisfaction and higher sales. Customers appreciated the intricate designs, which contributed to repeat business and positive reviews, significantly boosting our shop’s reputation.

This experience underscores how the laser engraver not only enhances product quality but also drives business growth by meeting diverse customer needs efficiently.

Joseph Hernandez –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”

Robert Wang –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost efficiency. Fast, reliable, and solidly built—a true 5-star workhorse!”

John Williams –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost efficiency. Sturdy build, reliable performance, and rapid engraving speeds make it a true 5-star tool.”

Klaus Bernard –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and robust build quality. Highly reliable and a true game-changer for my workshop. Five stars!”

Gabriella Baker (verified owner) –

I used the LaserHawk LH3 Neje for a custom wooden nameplate project, and it was impressively precise. Carving intricate details was so smooth; I couldn’t believe how easy it made creating something that looks professionally done!

Susan Williams –

★★★★★ Excellent Laser Engraver! Impressive engraving quality & precision. User-friendly software & smooth operation. Fast engraving speed boosts productivity. Solid build & reliable performance.