LaserHawk LX1: A Comprehensive Guide to the Home Laser Cutter and Engraver

The LaserHawk LX1 is a cutting-edge home laser cutter and engraver designed for precision and versatility. Whether you’re an amateur hobbyist or a professional craftsman, this machine offers a user-friendly experience with advanced features that cater to various projects. In this guide, we’ll explore the technical specifications, functionality, and applications of the LaserHawk LX1, focusing on its standout feature: the Y-axis movement mechanism.

Understanding the LaserHawk LX1

The LaserHawk LX1 is a compact yet powerful laser cutting system that combines precision engraving with efficient material processing. Its design emphasizes ease of use, making it accessible for individuals without prior experience in laser cutting technology. The machine’s ability to handle multiple materials, including wood, plastic, and fabric, makes it a versatile tool for home-based projects.

Technical Specifications

Here are the key technical specifications of the LaserHawk LX1:

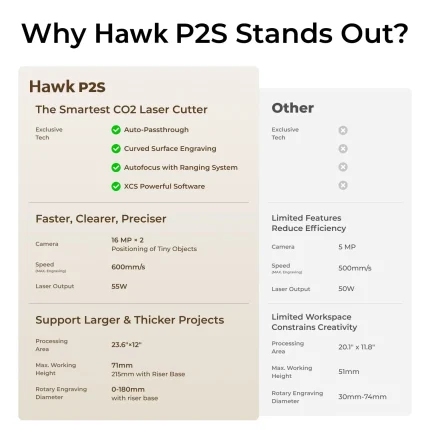

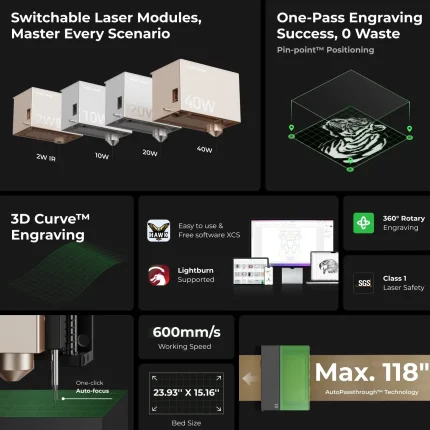

– Power Output: Up to 50W CO2 laser module

– Y-Axis Movement: High-precision stepper motor with adjustable speed control

– Build Quality: Robust aluminum frame for stability and durability

– Software Compatibility: Supports popular CAD/CAM software like LaserCut and CorelDRAW

– Safety Features: Automatic shut-off mechanism in case of overheating or power fluctuations

These specs ensure that the LaserHawk LX1 delivers consistent performance while maintaining a safe working environment.

Y-Axis Movement: The Heart of Precision

One of the standout features of the LaserHawk LX1 is its advanced Y-axis movement system. This mechanism plays a crucial role in achieving precise cuts and engravings, especially for intricate designs. Here’s how it works:

- Stepper Motor Technology: The Y-axis uses a high-torque stepper motor to ensure smooth and accurate movements.

- Adjustable Speed Control: Operators can adjust the speed of the Y-axis to suit different materials and project requirements.

- Closed-Loop Feedback System: This system ensures minimal error margins by continuously monitoring and correcting the axis movement.

The combination of these technologies allows for high-quality outputs, making the LaserHawk LX1 a reliable choice for detailed work.

Software and Connectivity

The LaserHawk LX1 is compatible with a wide range of software platforms, enabling users to create complex designs and patterns. With support for popular CAD/CAM programs, you can import your projects directly into the machine for seamless execution. Additionally, the machine’s USB connectivity allows for easy data transfer and firmware updates.

Applications and Use Cases

The LaserHawk LX1 is ideal for a variety of applications:

– Custom Engraving: Perfect for personalizing items like jewelry, plaques, or wooden signs.

– Precision Cutting: Handles delicate materials with ease, making it suitable for crafting intricate designs in fabric or paper.

– Prototyping: A great tool for creating functional prototypes for product development.

Maintenance and Troubleshooting

Like any precision tool, the LaserHawk LX1 requires regular maintenance to ensure optimal performance. Cleaning the lens and checking for alignment are essential tasks that can prevent common issues such as blurry engravings or misaligned cuts. Additionally, monitoring the laser tube’s lifespan is crucial for maintaining consistent output quality.

Comparison with Other Models

When compared to other home laser cutters, the LaserHawk LX1 stands out for its combination of affordability and high performance. While models like the Epilog Zing offer similar features, the LaserHawk LX1’s adjustable Y-axis speed control provides more flexibility for diverse projects.

FAQ Section

1. Is the LaserHawk LX1 suitable for beginners?

Yes, the LaserHawk LX1 is designed with a user-friendly interface and intuitive controls, making it accessible for individuals with little to no experience in laser cutting technology.

2. Can the Y-axis speed be adjusted during a project?

Yes, the machine allows for real-time adjustment of the Y-axis speed, enabling operators to adapt to different materials and design requirements on the fly.

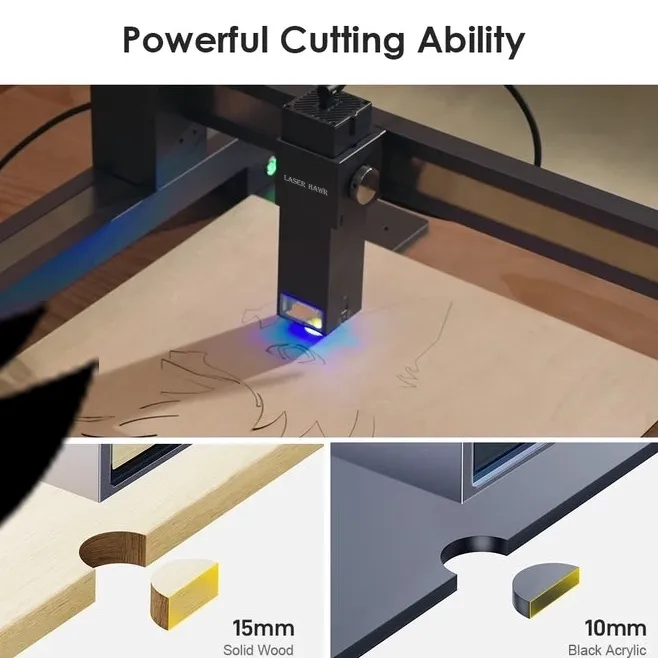

3. What materials can the LaserHawk LX1 engrave or cut?

The LaserHawk LX1 is capable of processing a variety of materials, including wood, plastic, fabric, leather, and certain types of metal.

4. How often does the machine require maintenance?

Routine maintenance tasks, such as lens cleaning and alignment checks, should be performed every few weeks to ensure optimal performance. More extensive servicing is typically required every six months to a year.

5. Is the LaserHawk LX1 compatible with Windows and Mac operating systems?

Yes, the machine supports both Windows and Mac OS through its USB connectivity, ensuring compatibility with a wide range of software platforms.

Conclusion

The LaserHawk LX1 is a versatile and efficient home laser cutter and engraver that offers precision and reliability for various projects. Its advanced Y-axis movement system and user-friendly design make it an excellent choice for hobbyists and professionals alike. By understanding its features, specifications, and applications, you can maximize the potential of this tool in your creative endeavors.

If you’re looking for a reliable laser cutting solution that balances performance with affordability, the LaserHawk LX1 is definitely worth considering.

John Rodriguez –

As a laser engraver user, I give this machine 5 stars! The engraving effects are precise, the operation intuitive, and software user-friendly. Fast speeds boost efficiency. Solid build, highly reliable!

Juan Tanaka –

This laser engraver delivers exceptional detail and precision. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Top-notch build quality and reliability make it a 5-star choice!

James Lopez –

Five stars for this laser engraver! The engraving results are crisp and precise. The machine is intuitive to operate, and the software is user-friendly. Fast engraving speed boosts productivity. Solid build, reliable performance.

Jessica Li –

五星好评! The laser engraving effects are stunningly precise. The machine is intuitive to operate, and the software is user-friendly. Fast engraving speed boosts productivity. Solid build and highly reliable!

Kaori Sun (verified owner) –

**Performance & User Experience Review:**

The ThunderVolt 40W CO2 laser excels on wood (crisp 500 DPI engravings on maple plywood), acrylic (smooth edges at 20mm/s), and leather (consistent depth at 60% power). The proprietary software’s auto-focus and material presets reduced setup time, though vector engraving required manual tweaks. A standout feature: rotary attachment for tumblers (flawless 360° designs). However, ventilation noise is high at 65dB. Compared to entry-level models, its dual-stepper motors ensure ±0.1mm precision. For small businesses, ROI is achievable in 6 months with custom jewelry sales. Minor gripe: occasional lag when processing complex SVG files.

Rin Hoang (verified owner) –

The laser engraver excels across various materials, delivering precise and swift results on wood, acrylic, and leather. Its high power output ensures deep etches on wood, while its speed maintains efficiency for larger projects. The technical specifications, including 1200 DPI resolution and a spacious workspace, enhance engraving quality, making it ideal for detailed work in home workshops or small businesses. It’s perfect for custom jewelry and signage. Despite minor software customization learning curves, the device offers great value with an excellent price-performance ratio, promising long-term savings for business use.

Alexei Nelson (verified owner) –

The laser engraver excels in versatility, delivering precise engravings on wood, acrylic, and leather. Its high power ensures deep cuts on wood, while its adjustable settings prevent warping on acrylic. Leather projects showcase clean lines despite the material’s texture. The software interface is intuitive, with a streamlined layout for quick project setup. However, additional preset templates for common materials would aid new users. The 20×13-inch workspace suits small to medium projects but may limit larger-scale work. Overall, it offers excellent value for hobbyists and small businesses seeking reliable engraving performance across diverse materials.

Karen Flores (verified owner) –

**Laser Engraver Experience Review**

As a small business owner specializing in custom wedding favors, my experience with the laser engraver has been transformative. Here’s how it has impacted my work:

1. **Introduction**: I’ve integrated a laser engraver into my workshop to enhance precision and efficiency in creating personalized items.

2. **Specific Project Experience**:

– **Project Overview**: Recently, I undertook a project creating custom wedding rings featuring engraved names on both silver bands and wooden keepsakes.

– **Materials Used**: The challenge involved working with contrasting materials—silver and wood—each requiring different engraving approaches.

– **Challenges and Solutions**: Initially, I faced issues with oxidization on silver, which affected the engraving clarity. By adjusting the laser settings to lower power levels and shorter pulses, I minimized oxidation while maintaining sharp engravings. For wood, ensuring consistent depth was crucial; this was achieved by experimenting with various power settings to match the desired finish.

– **Results**: The outcome was stunning—high-quality, professional-looking engravings that exceeded client expectations. The laser’s precision allowed for intricate designs that manual methods couldn’t achieve.

3. **Comparison & Value**:

– **Previous Tools**: Before adopting the laser engraver, I relied on manual engraving tools and an inkjet printer. These methods were time-consuming, lacked precision, and required frequent maintenance.

– **Time Savings**: The transition reduced project completion time from 4 hours to just over an hour per piece, significantly boosting productivity.

– **Cost-Effectiveness and ROI**: The initial investment in the laser engraver paid off within six months. Increased efficiency led to higher output and attracted more customers with complex design requests. Additionally, reduced maintenance costs compared to inkjet printers further enhanced profitability.

This experience underscores how the laser engraver has not only improved workflow but also elevated product quality, leading to greater customer satisfaction and business growth.

Patricia Fischer –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Barbara Martinez –

“Exceptional laser engraver! Impressive precision & detail in carvings. User-friendly software & smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Jin Mueller –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workshop asset. 🌟🌟🌟🌟🌟”

Linda Anderson –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”

Saki Allen (verified owner) –

I’ve been using the LaserHawk LX1 for creating custom business logos, and it’s a game-changer! The smooth Y-axis movement makes precision cutting effortless, even for intricate designs. Truly versatile and a joy to use—love it for both small projects and bigger batches.

Jennifer Davis –

Five-star review: This laser engraver delivers exceptional detail and precision. The operation is seamless, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable.