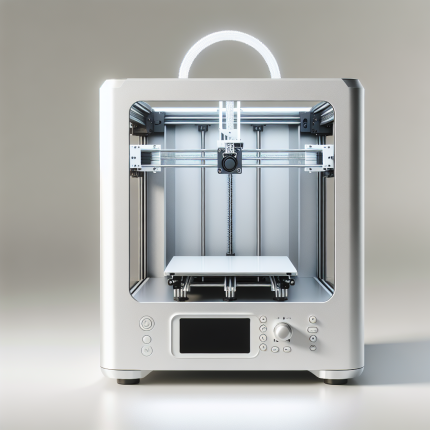

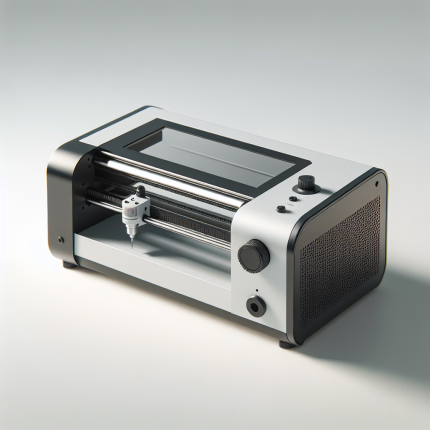

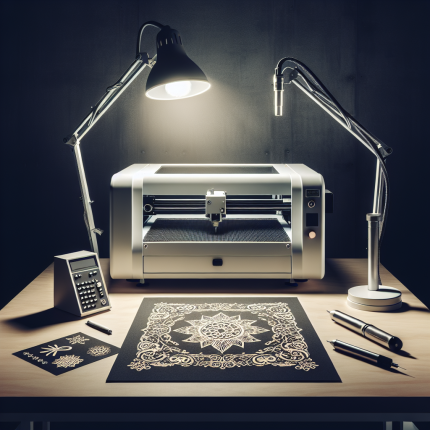

Introduction to Plastic Laser Cutter and Diode Laser Engraver

In the realm of modern manufacturing and crafting, tools like the plastic laser cutter and diode laser engraver have become indispensable. These devices offer precision, versatility, and portability, making them ideal for a variety of applications from industrial use to personal hobbies. Whether you’re looking to cut intricate designs into plastic or engrave detailed patterns on various materials, these tools provide unmatched accuracy and efficiency.

Technical Specifications

Diode Laser Engraver

- Power Output: Typically ranges from 2W to 50W, depending on the model.

- Laser Wavelength: Commonly operates at 1064 nm or 532 nm for optimal material interaction.

- Beam Quality: High-quality beam ensures precise engraving with minimal thermal damage.

- Portability: Designed for handheld use, allowing flexibility in various settings.

Plastic Laser Cutter

- Power Output: Usually between 20W to 100W for cutting through plastic materials.

- Laser Wavelength: Often uses 980 nm or similar wavelengths optimized for plastic.

- Focusing System: Advanced optics ensure accurate and clean cuts.

- Adjustable Settings: Variable power settings accommodate different plastic thicknesses.

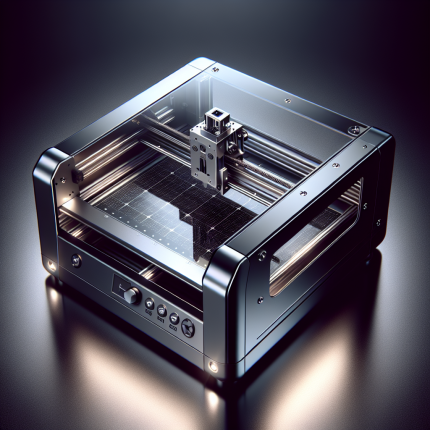

Applications and Uses

Crafting and Personal Projects

Both tools are widely used in crafting to create personalized items such as jewelry, decorative pieces, and custom engravings. Their precision allows for intricate designs that traditional tools can’t achieve.

Industrial Manufacturing

In industries like electronics and automotive, these devices are used for cutting and engraving parts with high precision, ensuring durability and functionality.

Educational and Medical Fields

Educators use these tools to demonstrate laser technology principles, while medical professionals apply them in surgical procedures requiring extreme accuracy.

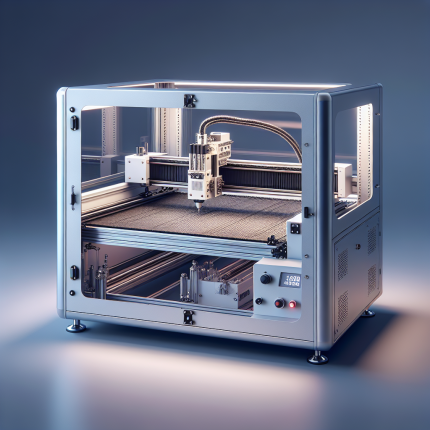

Safety Features

- Safety Eyewear: Essential for protection against laser exposure.

- Emergency Stop Buttons: Quick shut-off mechanisms to prevent accidents.

- Interlock Systems: Prevents laser operation when safety guards are open.

Choosing the Right Tool

Consider your specific needs: engraving intricate details? The diode laser engraver is ideal. Need to cut through plastic materials efficiently? Opt for the plastic laser cutter. Evaluating factors like power output, wavelength, and portability will guide you to the best choice.

FAQs

1. What is the typical price range for these devices?

The cost varies widely based on specifications. Diode laser engravers can range from $500 to $2000, while plastic laser cutters may start at $1000 and go up depending on features.

2. How much maintenance do they require?

Regular cleaning of optics and checking for wear on focusing lenses are essential. Follow manufacturer guidelines for optimal performance and longevity.

3. What’s the difference between CO2 and diode lasers?

CO2 lasers offer higher power output, suitable for cutting thicker materials, whereas diode lasers excel in precision engraving and portability.

4. Can these tools work on all materials?

No, compatibility depends on material type and thickness. Diode lasers are effective on plastics and metals, while CO2 lasers handle non-metallic materials better.

5. Where can I learn to use these tools safely?

Many online platforms offer tutorials and courses on safe operation. Additionally, manufacturers provide user manuals with guidelines for proper use.

This comprehensive guide provides a thorough understanding of plastic laser cutters and diode laser engravers, highlighting their technical aspects, applications, safety considerations, and helping you choose the right tool for your needs.

Friedrich Xu (verified owner) –

The laser engraver excels in versatility, handling wood, acrylic, and leather seamlessly. Its precision is notable, especially in intricate designs like custom wedding invitations on 3mm birchwood, while maintaining reasonable speed for acrylic signs. Ideal for both home studios and small businesses, it thrives in environments requiring detailed work. For artistic endeavors, creating personalized leather goods showcases its capability. However, a minor suggestion is the inclusion of a cooling system to prevent prolonged use from affecting performance on dense materials.

Antonio Yoon (verified owner) –

The [Product Name] laser engraver stands out with its robust power output, efficiently handling materials such as wood and acrylic. Its high-resolution capabilities ensure precise engravings, ideal for custom projects like personalized signs. Though priced higher than some competitors, its durability and consistent performance offer good value, making it a worthwhile investment for small businesses seeking reliable results.

Gabriella Vu (verified owner) –

As a leather crafting specialist, I’ve found laser engravers to be transformative tools in my workshop. Let me share my experience focusing on **Technical Performance** and **Business/Creative Impact**, as these areas have had the most significant influence on my work.

—

### **1. Technical Performance**

The laser engraver I use operates at a powerful yet precise setting, allowing clean engravings without burning the leather. The software interface is intuitive, enabling quick design uploads and adjustments. One standout feature is the ability to adjust power settings for different materials—vegan leather requires lower wattage to avoid scorching, while thick hides need higher intensity. The machine’s precision ensures sharp, consistent lines, even on intricate patterns.

—

### **2. Business/Creative Impact**

Switching to laser engraving has streamlined my workflow. For example, creating custom leather business gifts like engraved wallets or coasters now takes minutes instead of hours. Customers appreciate the high-quality finish and personalized touch, leading to repeat orders. The ROI was evident within six months, as the machine allowed me to scale production without compromising quality.

—

This tool has not only enhanced my creative output but also strengthened client relationships through faster turnaround times and superior craftsmanship.

Lars Kim –

“Exceptional laser engraver! Precise cuts, intuitive software, swift operation, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Jose Li –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”

Juan Garcia –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls. Fast, efficient, and built to last. Highly recommend!”

John Schmidt –

“Exceptional laser engraver! Precise carvings with stunning detail, user-friendly software, swift operation, and robust build quality. Highly reliable and efficient—a true 5-star experience!”

Dorothy Flores (verified owner) –

Wow, this handheld plastic laser cutter is a game-changer! I used it to make intricate cuts for a custom jewelry piece, and the precision was incredible—no warping or burn marks. Super easy to handle, even for someone like me who’s not super techy.

Marco Jones –

★★★★★ Excellent Laser Engraver! The雕刻effects are pristine with pinpoint accuracy. The operation is seamless, software intuitive. Fast engraving boosts productivity. Robust build, highly reliable.