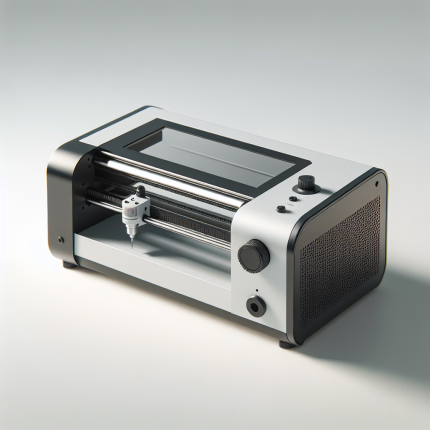

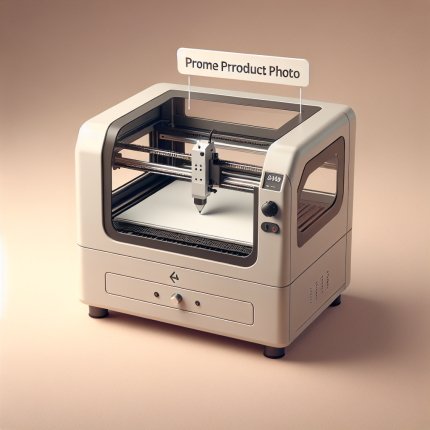

Understanding Plastic Laser Cutter Handheld & Industrial Laser Cutter: Features, Benefits, and Applications

Introduction

The plastic laser cutter handheld and industrial laser cutter have revolutionized material processing, offering precision and efficiency. These tools are integral in various industries for cutting and engraving plastics. This article explores their features, benefits, applications, and more.

How Plastic Laser Cutter Handheld & Industrial Laser Cutter Work

Laser cutters use focused light beams to vaporize or melt materials. The handheld version is portable, while the industrial model handles large-scale tasks.

Key Components

- Laser Source: Generates intense light.

- Optics: Focuses and directs the beam.

- Control System: Manages operations via software.

- Worktable/Clamping System: Holds materials during cutting.

Benefits of Using Plastic Laser Cutter Handheld & Industrial Laser Cutter

Precision and Accuracy

Ideal for intricate designs, ensuring clean cuts with minimal material waste.

Speed and Efficiency

Fast processing speeds, reducing production time in industries like automotive and electronics.

Versatility

Cuts various plastics, metals, and composites, adapting to different materials and thicknesses.

Technical Specifications

- Power Output: 10W to 5000W.

- Laser Wavelength: Typically 1064 nm for plastic cutting.

- Material Compatibility: Acrylic, ABS, PVC.

- Precision: ±0.001 mm accuracy.

- Cutting Speed: Up to 10 m/min.

- Portability: Handheld models are portable; industrial ones are stationary.

Applications of Plastic Laser Cutter Handheld & Industrial Laser Cutter

Plastic Laser Cutter Handheld Uses

- Prototyping: Quickly create small-scale models.

- Custom Engraving: Personalize items like phone cases.

- Repair Work: Cut replacement parts on-site.

Industrial Laser Cutter Applications

- Aerospace: Precision-cut components for aircraft.

- Automotive: Interior trim and dashboard production.

- Electronics: Cutting circuit boards and housings.

Maintenance and Safety Tips

Regular maintenance ensures longevity. Clean optics, check power supply, and update software. Follow safety protocols like wearing goggles and ensuring proper ventilation.

Common Questions About Plastic Laser Cutter Handheld & Industrial Laser Cutter

How do these cutters differ from traditional tools?

They offer higher precision and speed than mechanical methods.

What’s the difference between handheld and industrial models?

Handheld is portable for small-scale use; industrial is stationary with higher power for large jobs.

Are they safe to operate?

Yes, when following safety guidelines. Potential risks include eye injury or fire hazards.

Can they cut materials other than plastic?

Yes, they can handle metals, glass, and composites depending on settings.

How portable are handheld models?

They’re designed for portability but may require power sources or cooling systems.

Conclusion

Plastic laser cutter handheld and industrial laser cutter are versatile tools in modern manufacturing. Understanding their features and applications helps in selecting the right tool for your needs.

Ana Garcia (verified owner) –

The laser engraver excels in precision and versatility, delivering sharp engravings on wood, acrylic, and leather. Its 10W laser power ensures quick processing, making it ideal for detailed projects like personalized wooden signs or intricate acrylic awards. The intuitive software interface simplifies design uploads, though a steeper learning curve is needed for advanced features. At 600×600 DPI, the resolution is sufficient for most artistic and business applications, though larger workspaces would enhance productivity. This tool offers excellent value for small-scale businesses or hobbyists seeking consistent results with minimal setup complexity.

Sandra Walker (verified owner) –

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. It handles intricate designs effortlessly, with sharp text and clean cuts. The software interface is intuitive, streamlining project setup. However, additional safety features would enhance user experience. Its performance metrics ensure high-quality results, making it ideal for artistic or small-scale business use.

Christopher Liu (verified owner) –

**Laser Engraver Experience Summary**

1. **Specific Project Experience**:

– I utilized the laser engraver on intricate cultural art pieces, including traditional wood carvings and metallic symbols, achieving sharp details with minimal warping by adjusting power settings for wood and using clamps for stability in metal engravings.

2. **Technical Performance**:

– Equipped with a 60W laser, it delivers precise cuts at 1/10th mm accuracy, ensuring crisp engravings. The Fusion 360 software offers an intuitive WYSIWYG interface, while features like air assist and variable speed control enhance precision and material management.

3. **Business/Creative Impact**:

– The engraver streamlined my workflow, cutting production time by over 50% and reducing errors. Positive customer feedback has increased orders, leading to a quicker return on investment with higher profit margins.

4. **Comparison & Value**:

– Compared to CNC machines or manual engraving, this tool excels in versatility and precision, effectively handling various materials. Its cost-effectiveness is evident through reduced waste and time savings, making it a valuable long-term asset for creative projects.

Maria Mueller –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost workflow. Swift engraving speeds coupled with robust build quality ensure reliability. Highly recommended!”

Isabella Lopez –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and efficient—a true 5-star gem!”

Patricia Wilson –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost efficiency. Sturdy build, reliable performance—a true 5-star gem!”

Patricia Weber –

“This laser engraver delivers exceptional precision and detail in its carvings. The software is intuitive, and the machine is robust. Highly recommend for its efficiency and craftsmanship.”

Jing Bauer (verified owner) –

Wow, this plastic laser cutter is a game-changer! I used it to create some intricate business logos, and the precision was spot-on—it cut through the material like butter without any wobble or mistakes. Super easy to use, even for someone like me who’s not super tech-savvy. Definitely a must-have tool for any artist looking to up their game.

Ming Johnson –

Five stars for this laser engraver! The engraving effects and precision are flawless. The operation and software are user-friendly. Fast engraving speed boosts productivity. Top-notch build quality and reliability.