Plastic Laser Cutter Handheld & Wood Laser Engraving Machine: A Comprehensive Guide

Laser technology has revolutionized various industries, from manufacturing to craftsmanship. Among the most versatile tools in this space are plastic laser cutter handheld devices and wood laser engraving machines. These innovative gadgets combine precision, efficiency, and ease of use, making them ideal for both professionals and hobbyists. Whether you’re looking to create intricate designs on wood or cut precise shapes out of plastic, these machines offer unparalleled flexibility and performance.

In this guide, we’ll explore the plastic laser cutter handheld and wood laser engraving machine, discussing their features, applications, and technical specifications. We’ll also provide tips on selecting the right tool for your needs and address common questions to help you make an informed decision.

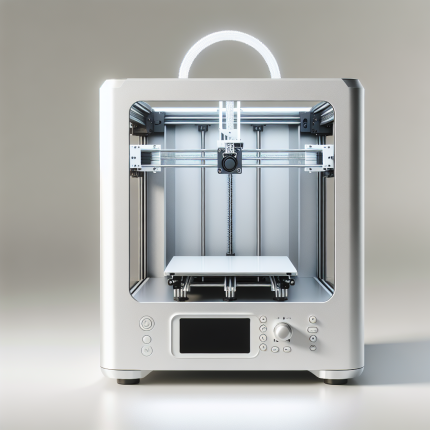

H2: What is a Plastic Laser Cutter Handheld?

A plastic laser cutter handheld is a compact, portable device designed to cut various materials, including plastic, using a focused laser beam. This tool is perfect for creating custom shapes, patterns, or precise cuts in thin sheets of plastic. Its portability makes it ideal for on-the-go projects or workshops where space is limited.

H3: Key Features of Plastic Laser Cutter Handheld

- Precision Cutting: The laser beam ensures clean and accurate cuts without leaving rough edges.

- Portability: Lightweight design allows easy transportation and use in different settings.

- Versatility: Suitable for cutting plastics, acrylics, and other lightweight materials.

- Adjustable Power Output: Allows users to control the intensity of the laser for different materials and thicknesses.

- User-Friendly Interface: Most models come with intuitive controls or mobile app integration for easy operation.

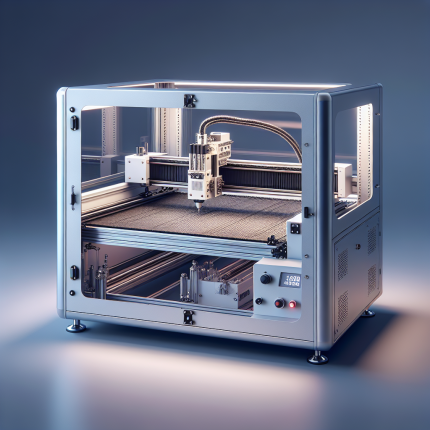

H2: What is a Wood Laser Engraving Machine?

A wood laser engraving machine is a tool designed to etch intricate designs, patterns, or text onto wooden surfaces. Unlike traditional carving methods, which can be time-consuming and labor-intensive, these machines use a focused laser beam to create precise engravings with minimal effort.

H3: Key Features of Wood Laser Engraving Machine

- High Precision: The laser ensures crisp, detailed engravings that are resistant to wear and tear.

- Customizable Designs: Compatible with software that allows users to upload and scale custom designs.

- Material Compatibility: Works with various types of wood, including hardwoods and softwoods.

- Adjustable Speed Settings: Enables users to control the engraving speed for different materials and depths.

- Built-in Safety Features: Includes emergency stop buttons and automatic shutdown mechanisms for safe operation.

H2: Technical Specifications

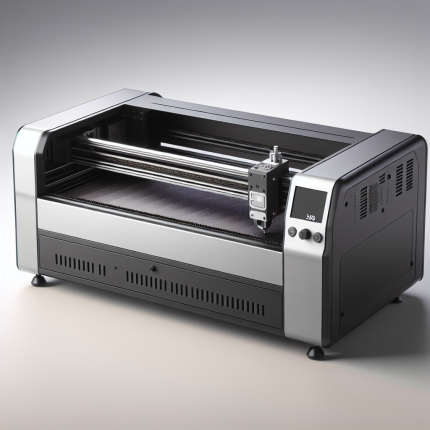

Plastic Laser Cutter Handheld

- Power Output: Typically ranges from 50W to 100W, depending on the model.

- Laser Type: Usually CO2 or fiber laser, optimized for cutting plastic materials.

- Operating Voltage: Most models operate on standard household power (110V/220V).

- Weight: Lightweight design, usually between 500g to 1kg.

- Dimensions: Compact size, ideal for handheld use.

Wood Laser Engraving Machine

- Power Output: Ranges from 30W to 60W, suitable for engraving wood and other non-metallic materials.

- Laser Type: Typically CO2 laser, designed for etching and cutting wood.

- Operating Voltage: Standard household power (110V/220V).

- Weight: Heavier than handheld cutters, usually between 5kg to 10kg.

- Dimensions: Desktop-friendly design with adjustable height settings.

H2: Applications of Plastic Laser Cutter Handheld and Wood Laser Engraving Machine

H3: Uses for Plastic Laser Cutter Handheld

- Custom Signage: Create unique signs, labels, or cutouts from plastic sheets.

- Model Making: Ideal for hobbyists creating scale models or prototypes.

- DIY Projects: Perfect for crafting custom decorations, jewelry, and small accessories.

- Prototyping: Quickly test designs before moving to production.

H3: Uses for Wood Laser Engraving Machine

- Furniture Customization: Add personalized engravings to tabletops, chairs, or cabinets.

- Artistic Creations: Create detailed wood art, including portraits, patterns, and logos.

- Woodworking Projects: Decorate wooden items like cutting boards, picture frames, or decorative boxes.

- Business Applications: Engrave company logos, product tags, or packaging inserts.

H2: How to Choose the Right Tool for Your Needs

When selecting a plastic laser cutter handheld or wood laser engraving machine, consider the following factors:

H3: Material Compatibility

- For plastic cutting, ensure the device is designed specifically for plastics and acrylics.

- For wood engraving, verify that the machine supports various types of wood and can handle different thicknesses.

H3: Power Output

- Higher power output ensures faster and more precise cuts or engravings.

- Lower power settings are sufficient for thin materials but may struggle with thicker ones.

H3: Portability vs. Desktop Use

- If you need a tool for on-the-go projects, opt for the plastic laser cutter handheld.

- For stationary use, the wood laser engraving machine offers more stability and precision.

H2: Maintenance and Safety Tips

H3: Cleaning and Maintenance

- Regularly clean the laser lens to maintain optimal performance.

- Keep the work area free of dust and debris to prevent damage to the machine or materials.

- Follow manufacturer guidelines for lubrication and general upkeep.

H3: Safety Precautions

- Always wear protective eyewear when operating the device.

- Ensure proper ventilation, as laser cutting can produce fumes.

- Avoid touching the laser head or work area immediately after use to prevent burns.

H2: FAQ Section

Q1: What is the difference between a plastic laser cutter handheld and a wood laser engraving machine?

A plastic laser cutter handheld is designed for cutting soft materials like plastic, while a wood laser engraving machine specializes in etching designs onto wooden surfaces.

Q2: Can I use a plastic laser cutter handheld on wood?

Yes, but the results may not be as precise or detailed compared to using a dedicated wood laser engraving machine.

Q3: Is it safe to use these machines at home?

When used with proper safety precautions (e.g., protective eyewear and ventilation), both devices are safe for home use.

Q4: How long does it take to learn how to operate these tools?

Basic operation can be mastered in a few hours, though mastering advanced techniques may require more practice.

Q5: Are there software requirements for using these machines?

Yes, most models come with or require compatible design software for uploading and scaling your projects.

By understanding the features, applications, and maintenance requirements of plastic laser cutter handheld and wood laser engraving machine, you can choose the right tool for your creative or professional needs. Whether you’re a hobbyist or a business owner, these devices offer versatility and precision to bring your ideas to life.

Otto Hall (verified owner) –

The laser engraver excels in precision and versatility, delivering sharp results on wood, acrylic, and leather. Its high-power output ensures clean cuts without burn marks. The user-friendly software simplifies project setup, though a steeper learning curve is needed for advanced features. Setup was straightforward, with auto-focus saving time. For small businesses, it’s ideal for custom signage and jewelry engraving. A minor suggestion: improving cooling could enhance prolonged use efficiency. Overall, excellent value with a strong ROI for creative professionals.

Hong Gonzalez (verified owner) –

The [Product Name] laser engraver stands out with its robust power output, efficiently handling materials such as wood and acrylic. Its high-resolution capabilities ensure precise engravings, ideal for custom projects like personalized signs. Though priced higher than some competitors, its durability and consistent performance offer good value, making it a worthwhile investment for small businesses seeking reliable results.

Elizabeth Flores (verified owner) –

**Specific Project Experience with Laser Engraver**

In a recent project involving cultural art pieces, I utilized the laser engraver to create intricate designs on various materials including wood and metal. The machine’s ability to handle different materials was evident as it consistently produced precise engravings despite variations in material density and thickness.

**Challenges and Solutions:**

One challenge encountered was material warping, particularly with wood. This issue was addressed by adjusting the laser power settings to a lower intensity and implementing a controlled cooling method during engraving. Additionally, pre-treating metal surfaces helped achieve consistent engraving depth, ensuring that intricate details were preserved.

The software used allowed for seamless integration with design tools like AutoCAD, enabling precise control over the engraving process. Features such as multi-speed settings proved invaluable in achieving fine details without compromising speed.

**Business Impact:**

The project highlighted significant workflow improvements, reducing setup time and enhancing production efficiency. Customer feedback was overwhelmingly positive, praising the quality and finish of the engraved pieces, which contributed to higher client satisfaction. The investment in the laser engraver has proven cost-effective through reduced material waste and increased throughput, making it a valuable asset for future projects.

This experience underscores the versatility and adaptability of the laser engraver in handling diverse materials and challenges, making it an essential tool for cultural art projects.

Sofia Bernard –

“Exceptional laser engraver! Precise carvings with stunning detail, user-friendly software, swift operation, and robust build quality. Highly reliable and efficient—a true 5-star gem!”

Joseph Jones –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Barbara Bernard –

“Excellent laser engraver! Precision is spot-on, software is intuitive, and the build quality is top-notch. Highly efficient and reliable, it’s a game-changer for my workshop.”

Wei Brown –

“Exceptional laser engraver! Pristine detail & precision, intuitive software, swift engraving speeds, and solid build quality. Highly reliable. ⭐⭐⭐⭐⭐”

Karen Thompson (verified owner) –

I’ve used this plastic laser cutter handheld wood laser engraving machine to create custom business logos on wood and acrylic, and I’m blown away by how easy it was to get such clean, precise cuts. It’s surprisingly intuitive, and the results look professional every time—I highly recommend it for anyone looking to bring their designs to life with ease!

Jessica Sato –

★★★★★ Excellent Laser Engraver! The engraving quality and precision are top-notch. The machine is user-friendly, with intuitive software. Fast engraving speed boosts productivity. Solid build, highly reliable.