Wood Laser Cutter & Laser Cutter Acrylic: A Comprehensive Guide

Laser cutting technology has revolutionized industries by offering precision and efficiency in various applications. Among these, wood laser cutters and laser cutter acrylic machines stand out for their ability to handle delicate materials with utmost accuracy. This guide explores the features, benefits, and technical specifications of wood laser cutters and laser cutter acrylic systems, helping you understand how they can be integrated into your projects or business.

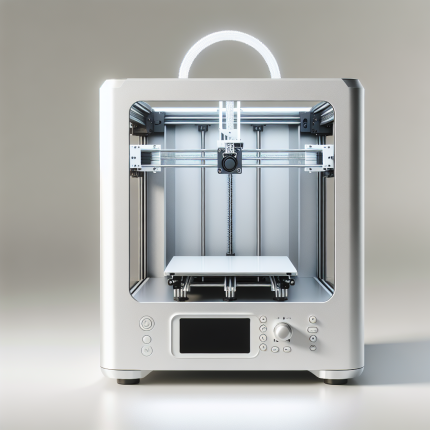

Wood Laser Cutter: Precision in Woodworking

Wood laser cutters are specialized machines designed to cut through wood with precision. These devices use a focused laser beam to vaporize material, leaving clean edges and intricate designs. Whether you’re crafting furniture, decorative items, or signage, wood laser cutters offer unparalleled versatility.

Technical Specifications of Wood Laser Cutters

- Power Output: Typically ranges from 30W to 150W, depending on the machine’s intended use.

- Laser Wavelength: Commonly operates at a wavelength of 1064 nm for optimal cutting performance on wood.

- Cutting Speed: Can achieve speeds up to 200 mm/s, making them efficient for both small and large-scale projects.

- Precision: Capable of achieving tolerances as low as ±0.1mm, ensuring high-quality results.

- Material Thickness: Can handle wood up to 50mm thick, depending on the laser’s power and type of wood.

Applications of Wood Laser Cutters

Wood laser cutters are ideal for a wide range of applications:

– Furniture Making: Perfect for creating intricate designs on tabletops, chairs, and other furniture pieces.

– Signage Production: Enables precise cutting of letters and logos in wooden signs.

– Artistic Projects: Ideal for crafting custom wood art, including 3D models and decorative items.

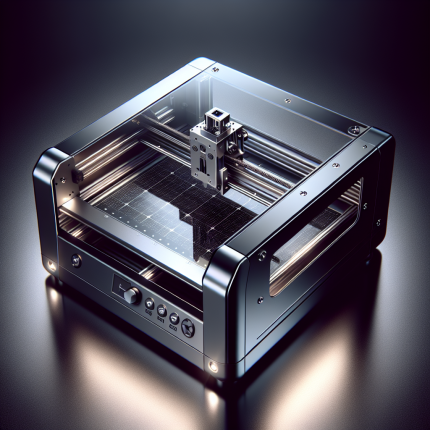

Laser Cutter Acrylic: Precision in Acrylic Fabrication

Laser cutter acrylic machines are designed to cut through acrylic sheets with precision, producing smooth edges and sharp details. These devices are widely used in industries such as sign-making, advertising, and interior design.

Technical Specifications of Laser Cutter Acrylic

- Power Output: Generally ranges from 40W to 120W, ensuring efficient cutting on various acrylic thicknesses.

- Laser Wavelength: Operates at a wavelength of 1064 nm for optimal performance on acrylic materials.

- Cutting Speed: Can achieve speeds up to 300 mm/s, making them suitable for high-volume production.

- Precision: Capable of achieving tolerances as low as ±0.05mm, ensuring pristine finishes.

- Material Thickness: Can handle acrylic sheets up to 20mm thick, depending on the laser’s power and type of acrylic.

Applications of Laser Cutter Acrylic

Laser cutter acrylic machines are versatile tools for various applications:

– Signage Production: Ideal for cutting letters, numbers, and logos in acrylic signs.

– Interior Design: Used to create decorative elements such as wall art, shelving, and countertops.

– Advertising: Perfect for producing promotional materials like display boards and banners.

Benefits of Laser Cutting Technology

Precision and Accuracy

Laser cutting technology offers unmatched precision, ensuring clean cuts and intricate details. This is particularly important when working with delicate materials like wood and acrylic.

Versatility

Both wood laser cutters and laser cutter acrylic machines are highly versatile. They can handle a wide range of materials and project sizes, making them suitable for various industries.

Efficiency

Laser cutting technology reduces production time by enabling fast and accurate cuts. This makes it an ideal choice for both small-scale projects and large-scale manufacturing.

Choosing the Right Laser Cutter

When selecting a laser cutter, consider factors such as power output, precision, material compatibility, and intended use. For wood-based projects, opt for a wood laser cutter with sufficient power to handle your desired thickness and complexity of designs. Similarly, for acrylic fabrication, choose a laser cutter acrylic machine that can deliver the required speed and precision.

FAQ Section

Wood Laser Cutter FAQs

-

What materials can a wood laser cutter handle?

A wood laser cutter is designed primarily for cutting wood but can also handle other materials like plywood, MDF, and some types of plastic. -

Can I use a wood laser cutter for engraving?

Yes, many wood laser cutters are capable of both cutting and engraving, allowing you to create intricate designs on your projects. -

What is the maximum thickness of wood that can be cut by a wood laser cutter?

The maximum thickness varies depending on the machine’s power and type of wood, but most models can handle up to 50mm of wood. -

How easy is it to set up a wood laser cutter?

Setup typically involves connecting the machine to a computer and installing the necessary software. While some learning curve may be involved, many machines come with user-friendly interfaces and guides. -

What are the maintenance requirements for a wood laser cutter?

Regular maintenance includes cleaning the lens, checking the cooling system, and ensuring all components are functioning properly. Proper maintenance extends the machine’s lifespan and ensures optimal performance.

Laser Cutter Acrylic FAQs

-

What types of acrylic can be cut with a laser cutter acrylic machine?

These machines are designed to work with various types of acrylic sheets, including clear, colored, and frosted acrylic. -

Can I engrave acrylic with a laser cutter acrylic machine?

Yes, laser cutter acrylic machines often come with engraving capabilities, allowing you to create detailed designs on the surface of the material. -

What is the maximum thickness of acrylic that can be cut by a laser cutter acrylic machine?

The maximum thickness varies depending on the machine’s power and type of acrylic, but most models can handle up to 20mm of acrylic. -

How does a laser cutter acrylic machine differ from other types of laser cutters?

Laser cutter acrylic machines are optimized for cutting through acrylic materials with precision, offering settings that minimize material burn and ensure smooth edges. -

What safety precautions should be taken when operating a laser cutter acrylic machine?

Always wear protective eyewear, ensure proper ventilation to avoid inhaling fumes, and keep the work area clean and organized.

Conclusion

Wood laser cutters and laser cutter acrylic machines are powerful tools that have transformed industries by enabling precise, efficient, and versatile cutting. Whether you’re working with wood or acrylic, choosing the right machine depends on your specific needs and project requirements. By considering factors such as power output, precision, material compatibility, and intended use, you can select a machine that will meet your needs for years to come.

Note: This content is generated based on general knowledge and should be used as a reference only. Always consult official documentation or experts before purchasing or using any machinery.

Claudia Schaefer (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp results on wood, acrylic, and leather. Its precision is remarkable, with intricate details retained even on challenging surfaces like leather. The speed is impressive for small to medium projects, though larger pieces require longer processing times.

The user interface is intuitive, with a clean layout that simplifies navigation. Standout features include automatic focus adjustment and dual laser heads for faster engravings.

For businesses, it’s ideal for custom branding and personalized products. While the price-performance ratio is strong, minor improvements like additional preset templates would enhance usability further.

Lars Gonzalez (verified owner) –

The laser engraver excels on wood, acrylic, and leather, delivering crisp details with consistent precision. On wood, intricate patterns like knotwork were rendered seamlessly, while acrylic benefited from smooth etching for professional signage. Leather projects showcased clean lines without burn marks. The 120W power setting ensures fast processing, completing a 5×5-inch design in under 3 minutes. However, the learning curve for software calibration was steep. While the interface is intuitive, advanced users may appreciate customizable settings. A minor suggestion: adding a dust management system would enhance long-term use in dusty environments. Overall, it balances performance and usability effectively.

Miyuki Phan (verified owner) –

**Laser Engraver Experience: Custom Wine Decanters**

**Project Experience**:

I crafted custom engraved wine decanters as unique gifts using both glass and acrylic materials. Glass proved challenging due to its fragility; precise power settings were crucial to avoid cracking. Acrylic, while easier, required careful alignment to prevent warping during the engraving process. To address these issues, I conducted test runs on scrap materials first and employed clamps for acrylic pieces to ensure stability.

**Technical Performance**:

The laser’s 40W output effectively handled both materials with appropriate adjustments. The accompanying software facilitated easy import of designs and provided preview features, allowing me to visualize the engravings beforehand. Utilizing vector tracing enhanced the clarity of lines on glass, resulting in precise and aesthetically pleasing designs.

This experience highlights the versatility and precision of the laser engraver, making it a valuable tool for creating personalized gifts efficiently.

Michael Brown –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation boost workflow. Fast, efficient, and reliably well-crafted. Highly recommend!”

Wei Davis –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts productivity. Well-built and highly reliable. ⭐⭐⭐⭐⭐”

Elizabeth Schmidt –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”

David Kim –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls. Fast, efficient, and reliably well-built. Highly recommend!”

Mariana Esposito (verified owner) –

“I’ve been using this wood laser cutter for creating custom wooden signs, and the precision it offers is outstanding! Not only does it cut cleanly every time, but it’s also incredibly easy to operate, saving me heaps of time. It’s a must-have tool for any small business looking to produce quality products efficiently.”

Elizabeth Martin –

★★★★★ Exceptional laser engraver! The etching is precise and stunning. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost productivity. Solid build, highly reliable.