The Ultimate Guide to CNC Laser Cutters

CNC (Computer Numerical Control) laser cutters have revolutionized the way we approach precision cutting, engraving, and design. Whether you’re working with wood, metal, plastic, or other materials, a CNC laser cutter offers unparalleled accuracy and versatility. This article explores everything you need to know about CNC laser cutters, their applications, benefits, and how they can transform your projects.

What is a CNC Laser Cutter?

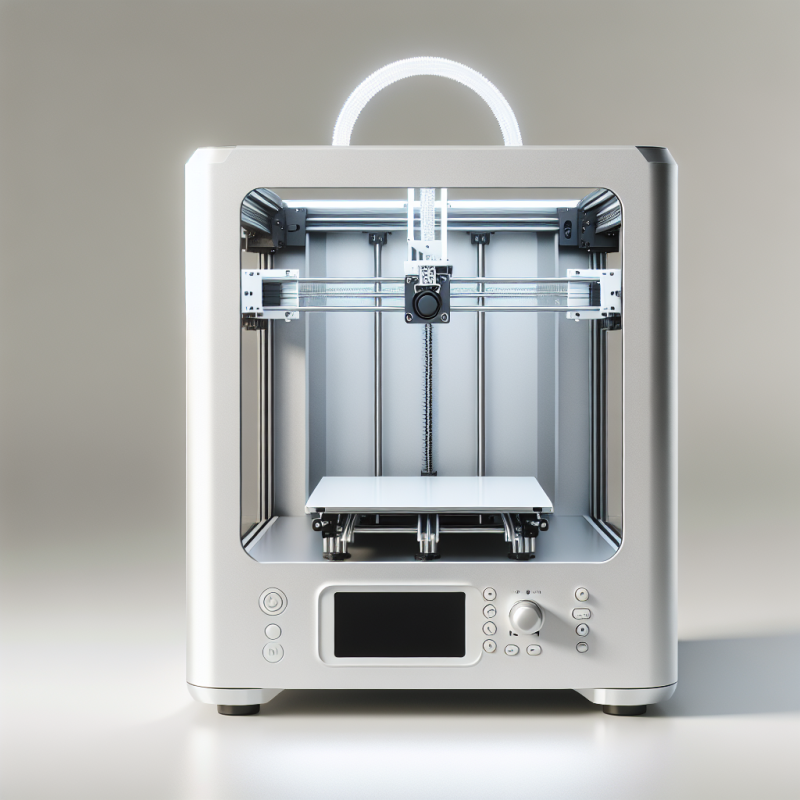

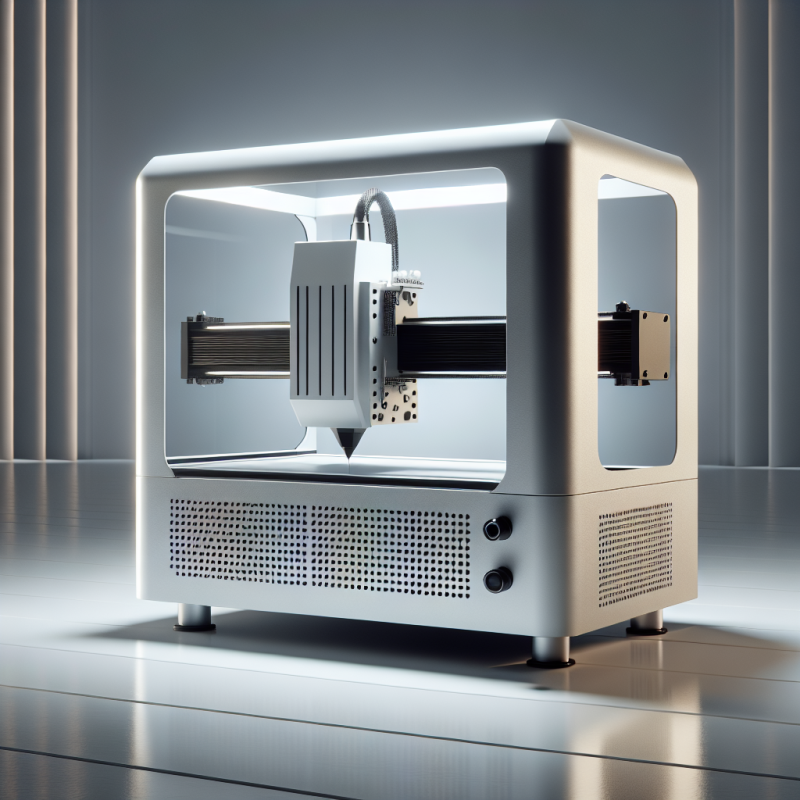

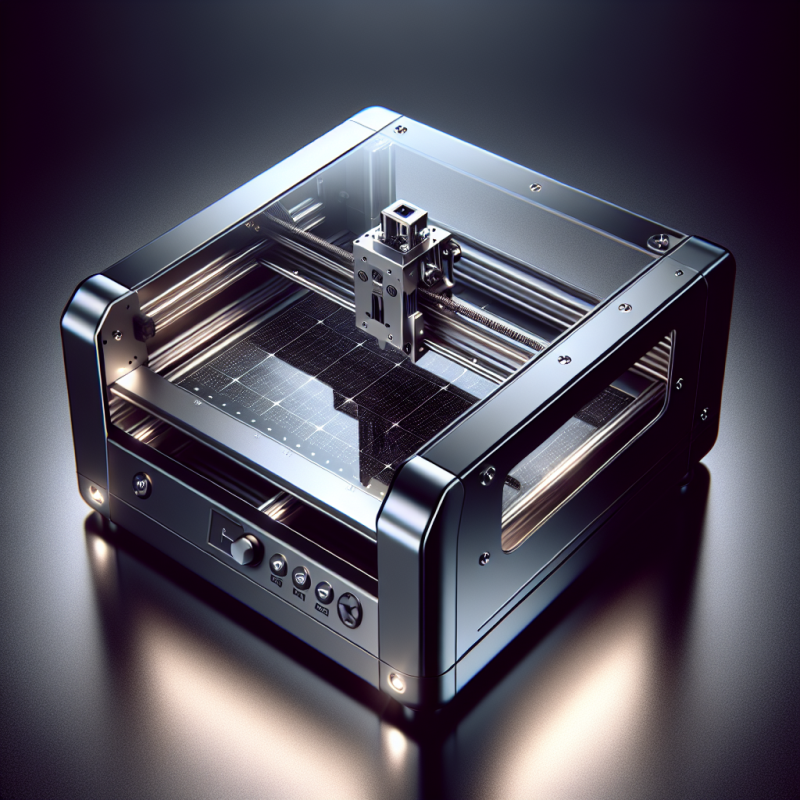

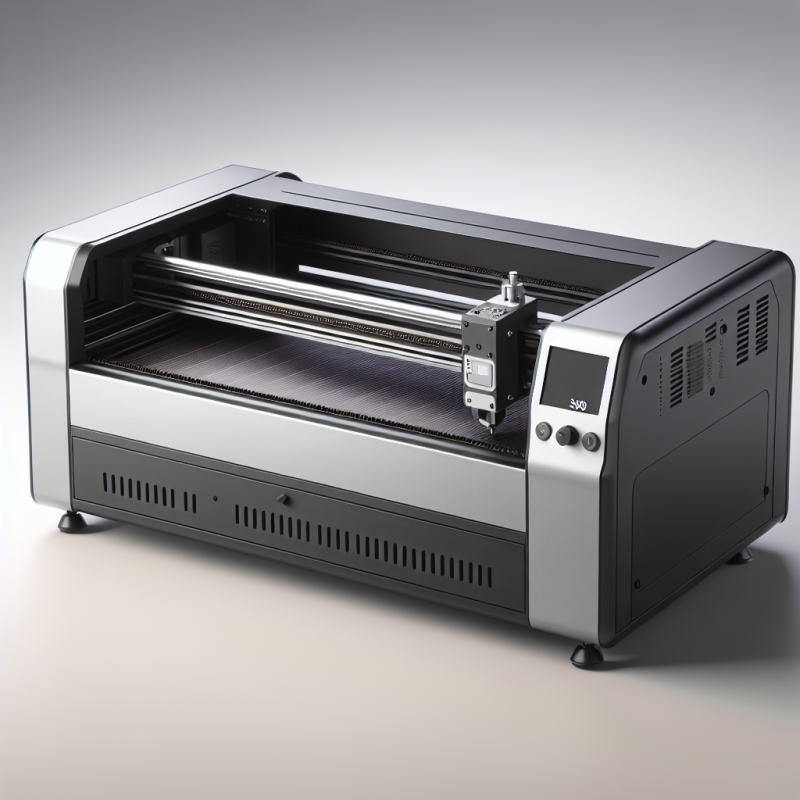

A CNC laser cutter is a machine that uses a focused laser beam to cut or engrave materials with high precision. Unlike traditional cutting methods, which often require manual operation and physical tools, a CNC laser cutter operates based on computer-generated designs. This allows for intricate patterns, complex shapes, and repeatable accuracy that would be difficult to achieve manually.

The machine works by directing the laser beam across the material’s surface, melting, burning, or vaporizing the material to create precise cuts or engravings. The process is controlled by a computer program, which reads the design file and translates it into instructions for the laser cutter’s movements.

Why Choose a CNC Laser Cutter?

The advantages of using a CNC laser cutter are numerous, making it an essential tool for businesses and hobbyists alike. Here are some key benefits:

- Precision and Accuracy: CNC laser cutters can achieve tolerances down to thousandths of a millimeter, ensuring precise cuts every time.

- Versatility: They work with a wide range of materials, including wood, metal, plastic, glass, and more.

- Speed and Efficiency: Once programmed, the machine can execute tasks rapidly, reducing production time significantly.

- Cost-Effective: Minimal material waste and reduced labor costs make CNC laser cutting a cost-effective solution in the long run.

- Customization: Complex designs and patterns that would be challenging to create manually can be easily produced using computer-aided design (CAD) software.

Applications of CNC Laser Cutters

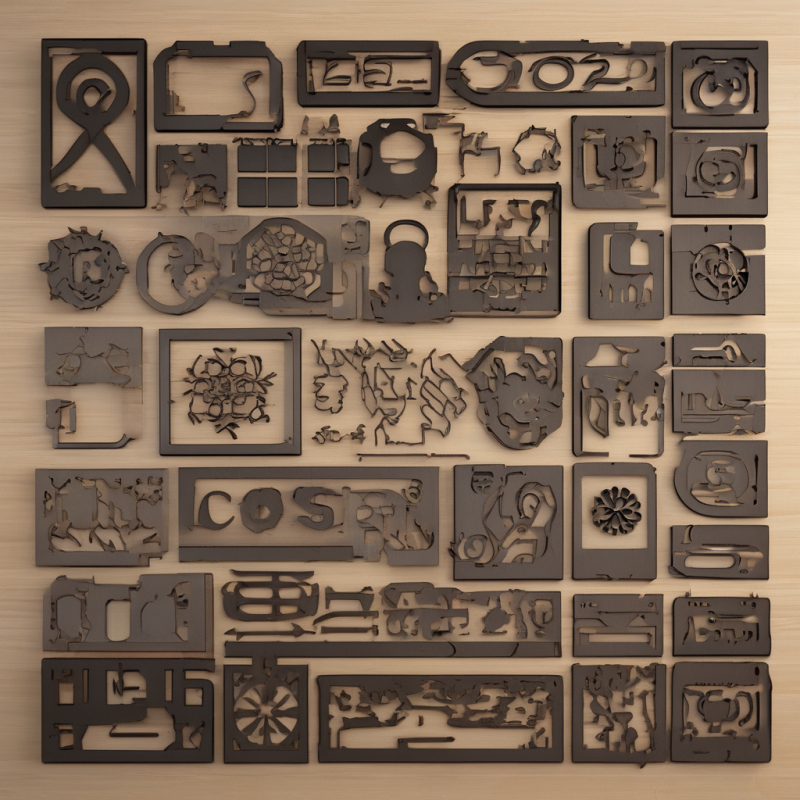

CNC laser cutters are used in various industries for a wide range of applications. Here are some common uses:

- Woodworking: Engraving logos, designs, or patterns on wooden products like furniture, signage, and decorative items.

- Metal Fabrication: Cutting metal sheets for automotive parts, machinery components, and architectural elements.

- Plastics: Shaping acrylics, polycarbonates, and other plastics for signs, displays, and prototypes.

- Glass and Ceramics: Engraving intricate designs on glassware, tiles, and ceramic products.

- Creative Design: Creating custom art pieces, jewelry, and decorative items with precision and detail.

Choosing the Right CNC Laser Cutter

When selecting a CNC laser cutter, it’s essential to consider your specific needs and budget. Here are some factors to keep in mind:

- Type of Material: Determine the types of materials you’ll be working with, as different lasers are suited for different substrates.

- Cutting Capacity: Consider the size and thickness of the materials you’ll need to cut. Larger machines can handle bigger projects but may require more space and investment.

- Budget: CNC laser cutters vary in price, so set a budget that aligns with your needs and expected return on investment.

- Add-On Features: Look for additional features like touchscreens, network connectivity, or integrated CAD software to enhance functionality.

If you’re looking for a reliable CNC laser cutter, the from Engraver Cutter Laser is an excellent choice. It offers precision, versatility, and ease of use, making it ideal for both small-scale projects and industrial applications.

Tips for Using a CNC Laser Cutter

To get the most out of your CNC laser cutter, follow these tips:

- Start with Simple Designs: Begin with basic shapes and patterns to familiarize yourself with the machine’s capabilities.

- Use Proper Safety Gear: Always wear protective eyewear, gloves, and ensure adequate ventilation when operating a laser cutter.

- Maintain Your Machine: Regularly clean and inspect your laser cutter to ensure optimal performance and longevity.

- Experiment with Materials: Test different materials to understand how the laser interacts with them and achieve desired results.

Frequently Asked Questions

Here are answers to some common questions about CNC laser cutters:

- Can I use a CNC laser cutter for both cutting and engraving? Yes, most CNC laser cutters can perform both functions depending on the settings and power levels used.

- What materials are not suitable for laser cutting? Some materials, like certain types of metal with reflective surfaces or highly conductive materials, may not be compatible. Always check compatibility before using a new material.

- How much training is needed to operate a CNC laser cutter? While some knowledge of CAD software and basic machining principles is helpful, many machines come with user-friendly interfaces that make them accessible even to beginners.

Conclusion

A CNC laser cutter is a powerful tool that can revolutionize your manufacturing or creative processes. Its precision, versatility, and efficiency make it an invaluable asset for businesses and hobbyists alike. If you’re ready to take your projects to the next level, consider investing in a high-quality CNC laser cutter like the from Engraver Cutter Laser.

Remember to always prioritize safety and experimentation when using your machine, and don’t hesitate to explore the vast possibilities that CNC laser cutting offers. Happy creating!

CNC Laser Cutter: A Comprehensive Guide

—

A CNC laser cutter is a revolutionary tool that combines precision, versatility, and efficiency for both industrial and creative applications. Here’s an in-depth overview of its features, benefits, applications, and considerations.

Key Benefits of CNC Laser Cutters:

1. **Precision and Accuracy:** Achieve tolerances down to thousandths of a millimeter.

2. **Versatility:** Works with various materials like wood, metal, plastic, glass, and ceramics.

3. **Speed and Efficiency:** Rapid execution of tasks once programmed.

4. **Cost-Effective:** Reduces material waste and labor costs.

5. **Customization:** Easily produce complex designs using CAD software.

Applications:

– **Woodworking:** Engraving logos and decorative items.

– **Metal Fabrication:** Cutting sheets for automotive parts and machinery.

– **Plastics:** Shaping acrylics for signs and displays.

– **Glass and Ceramics:** Engraving intricate designs.

– **Creative Design:** Crafting custom art, jewelry, and decorations.

Choosing the Right CNC Laser Cutter:

– Consider material type, cutting capacity, budget, and additional features like touchscreens or integrated software.

– The from Engraver Cutter Laser is a top choice for its precision and versatility.

Tips for Using CNC Laser Cutters:

1. Start with simple designs to familiarize yourself.

2. Use protective gear: eyewear, gloves, and ensure proper ventilation.

3. Regularly maintain the machine for optimal performance.

4. Experiment with different materials to understand their interaction with the laser.

Common Questions:

– **Q:** Can it perform both cutting and engraving?

– **A:** Yes, depending on settings and power levels.

– **Q:** What materials are not suitable?

– **A:** Reflective metals or conductive materials may not be compatible.

– **Q:** How much training is needed?

– **A:** Basic knowledge of CAD helps, but user-friendly interfaces make it accessible.

Conclusion:

Investing in a high-quality CNC laser cutter like the from Engraver Cutter Laser can elevate your projects. Prioritize safety and experimentation to unlock its full potential.

—

Happy creating!